A hydraulic brake system

A technology of hydraulic brake and frame, applied in the field of hydraulic brake system, can solve the problems of serious tire wear and braking distance, easy twisting of the handle, inconvenient use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

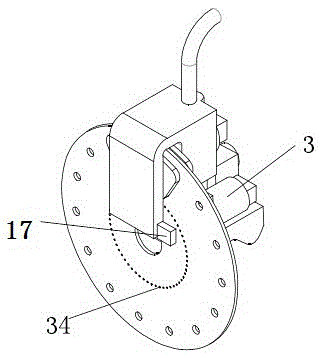

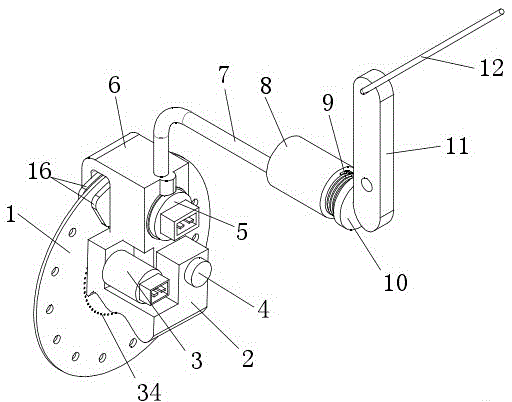

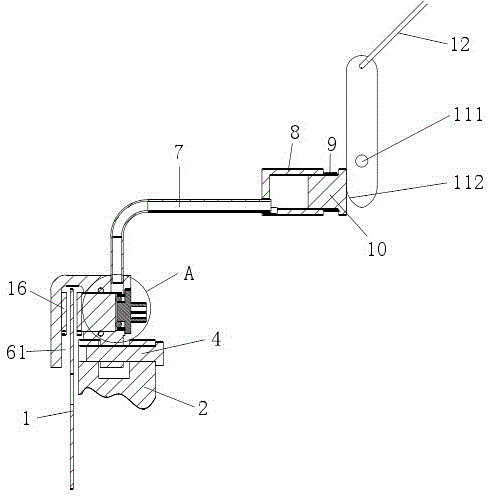

[0036] A hydraulic brake system, comprising a brake disc 1, a brake mechanism for braking the brake disc 1, and a drive mechanism for driving the brake mechanism, the drive mechanism includes a cable 12, a drive rocker arm 11 And the pressure oil cylinder 8, the upper end of the driving rocker arm 11 is connected with the drag cable 12, the lower end side is against the pressure piston 10 of the pressure oil cylinder 8, and the lower end side of the driving rocker arm is against the rear end of the pressure piston. The brake mechanism includes a brake caliper body 6 fixed on the vehicle frame 2, a friction plate 16 arranged on the brake caliper body 6, a mechanism for driving the friction plate 16 arranged in the brake caliper body 6 The hydraulic cylinder and the electromagnet 5 used to control the reciprocating movement of the brake piston 15 in the brake cylinder and the trigger device used to control the power on and off of the electromagnet, the pressure cylinder 8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com