Width-adjustable vehicle cabin and vehicle cabin verification platform thereof

A cabin and width technology, applied in the field of the cabin and its cabin verification platform, can solve the problems of high test costs, large gaps in the cabin environment, and data accuracy to be verified, and achieves guaranteed accuracy and strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

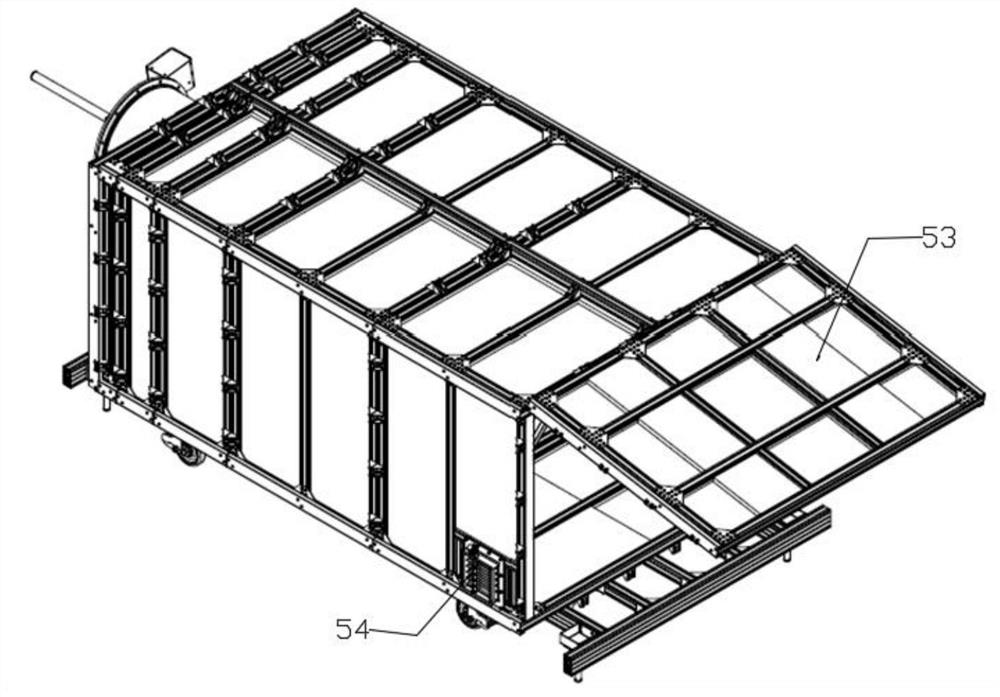

[0053] The vehicle cabin with adjustable width includes a head compartment assembly part 9, at least two vehicle compartment assembly parts 10, between any two vehicle compartment assembly parts 10, and between any one vehicle compartment assembly part 10 and the vehicle head compartment assembly part 9 can all be sealed and connected to each other, the cabin assembly part 10 at the front is sealed by the head cabin assembly part 9, and the cabin assembly part 10 at the rear is sealed by a replaceable tail end wall 11 to form the entire relatively sealed cabin;

[0054] The vehicle cabin assembly part 10 includes two upper and lower basic cabin frameworks 26, vehicle cabin adjustable plates 30 covering the upper and lower two basic cabin frameworks 26, and two sets of panels arranged between the two basic cabin frameworks 26. The opposite side wall assembly, the side wall assembly is in sealing contact with the cabin adjustable plate 30, when the relative position of the two si...

Embodiment 2

[0070] This embodiment optimizes the cabin air pressure regulating assembly 54 of the first embodiment.

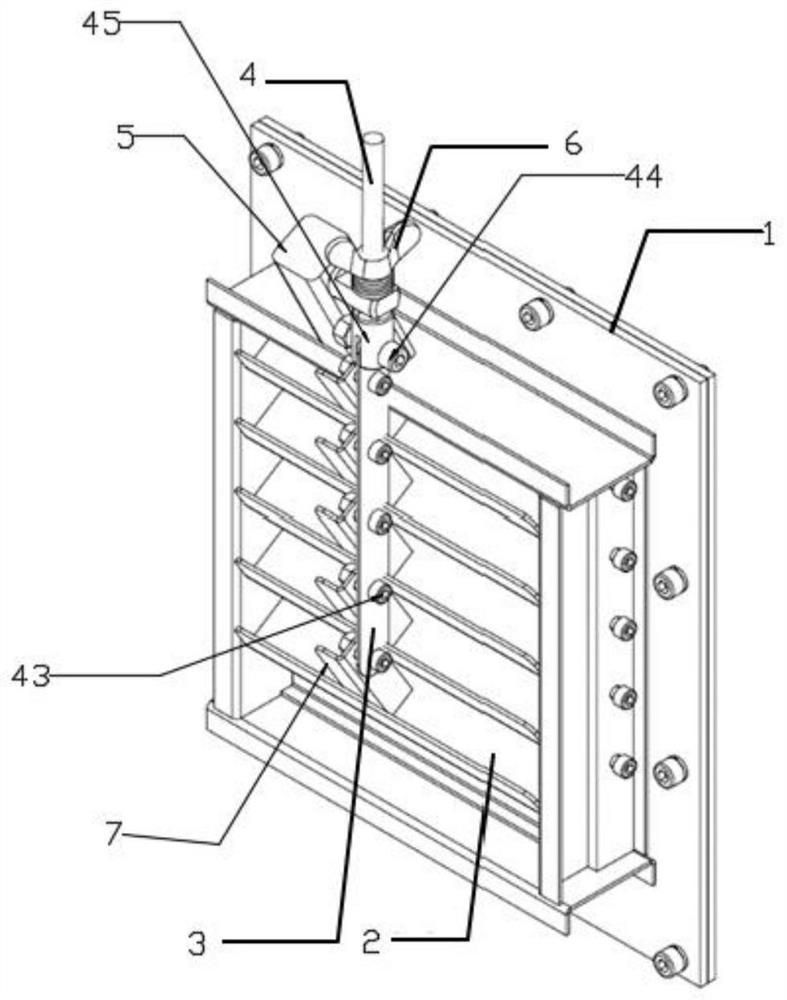

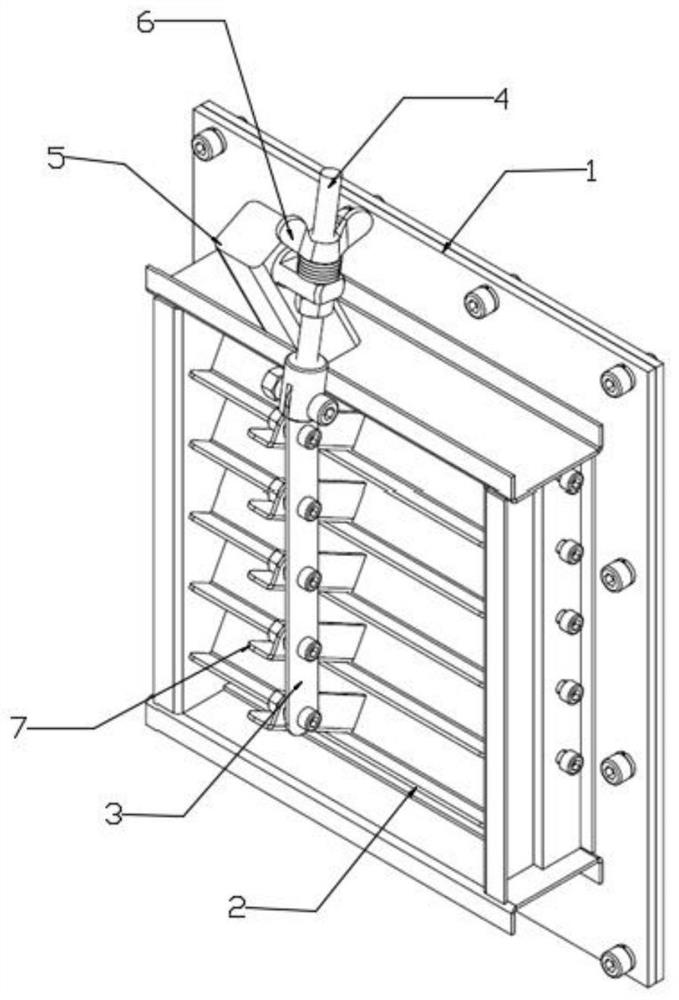

[0071] Preferably, the cabin air pressure adjustment assembly 54 includes a louver positioning frame 1, a louver leaf 2 sequentially installed on the window of the louver positioning frame 1, and an opening and closing angle for adjusting the louver leaf 2. the adjustment mechanism;

[0072]Wherein, the adjustment mechanism includes a louver opening connecting plate 3, an adjusting rod 4 whose one end is rotatably connected to the end of the louver opening connecting plate 3, a mounting seat 5 fixed on the louver positioning frame 1, and the same The shaft is fixedly sleeved on the outside of the adjustment rod 4 and the knob 6 is threadedly connected with the mounting seat 5, and a connecting body 7 is fixedly mounted on each louver leaf 2, and the connecting body 7 is rotatably connected to the On the shutter opening connecting plate 3.

[0073] The louver positioning ...

Embodiment 3

[0077] This embodiment optimizes the replaceable end wall 11 of Embodiment 1.

[0078] The replaceable end wall 11 is made up of two replaceable end walls, one of which is equipped with the continuously variable volume cylinder assembly 17 described in Embodiment 2, and the other end wall except Assemble steplessly variable volume cylinder assembly 17, also seal is equipped with the air pressure regulating device with cabin.

[0079] The continuously variable volume cylinder assembly 17 can fine-tune the volume in the cabin to make the simulated vehicle more accurate. The continuously variable volume cylinder assembly 17 is assembled directly above the air flow channel box 8 .

[0080] When simulating the car door test, select the tail end wall of assembling the stepless variable volume cylinder assembly 17 and the air pressure regulating device for the cabin for use;

[0081] Preferably, the continuously variable volume cylinder assembly 17 includes a cylinder body 19 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com