Automobile heating wire bending experiment equipment

An experimental equipment, heating wire technology, applied in the direction of using a stable bending force to test the strength of the material, using the repeated force/pulse force to test the strength of the material, and a measuring device, etc. To achieve the effect of reducing data discreteness and test data authenticity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

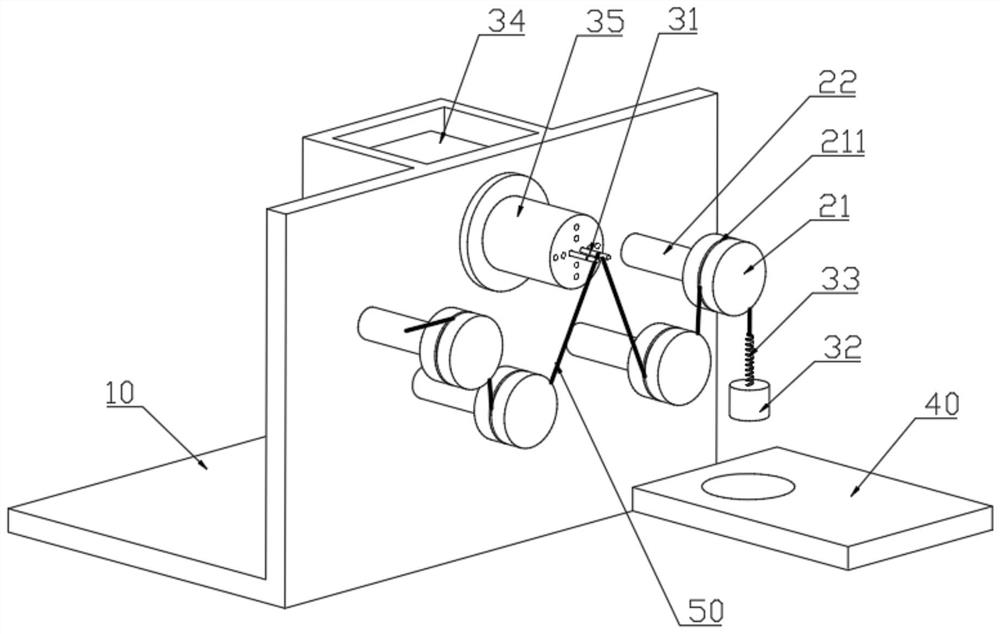

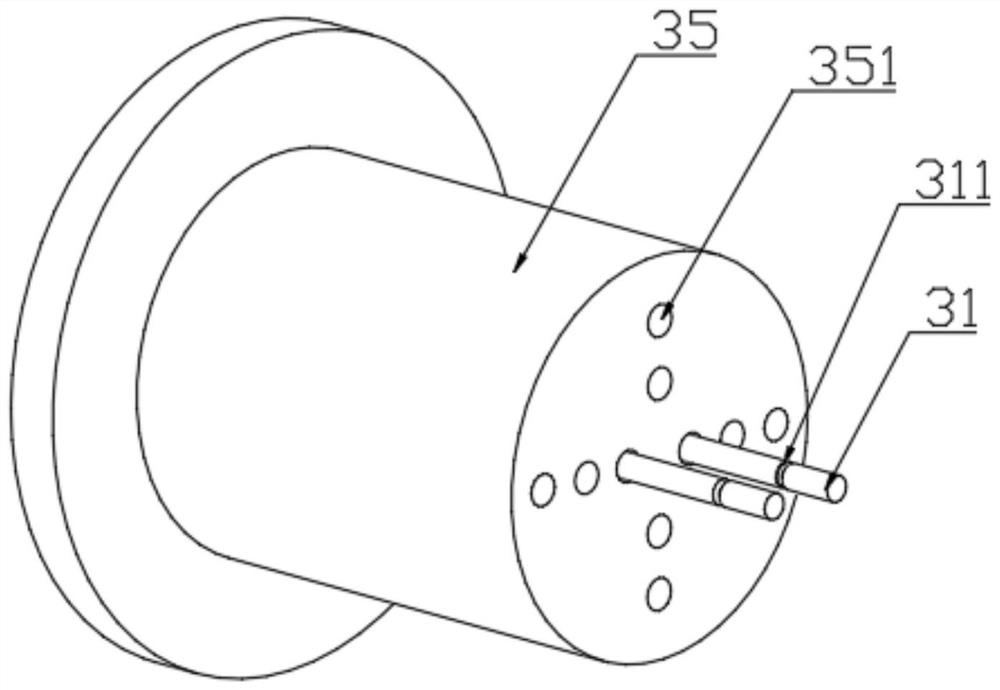

[0032] see Figure 1 to Figure 3 , a kind of automobile heating wire bending experiment equipment of the present embodiment, comprises mounting base 10, four sets of guide components, bending components, induction plate 40;

[0033] Specifically, each group of guide components is arranged on the mounting seat 10;

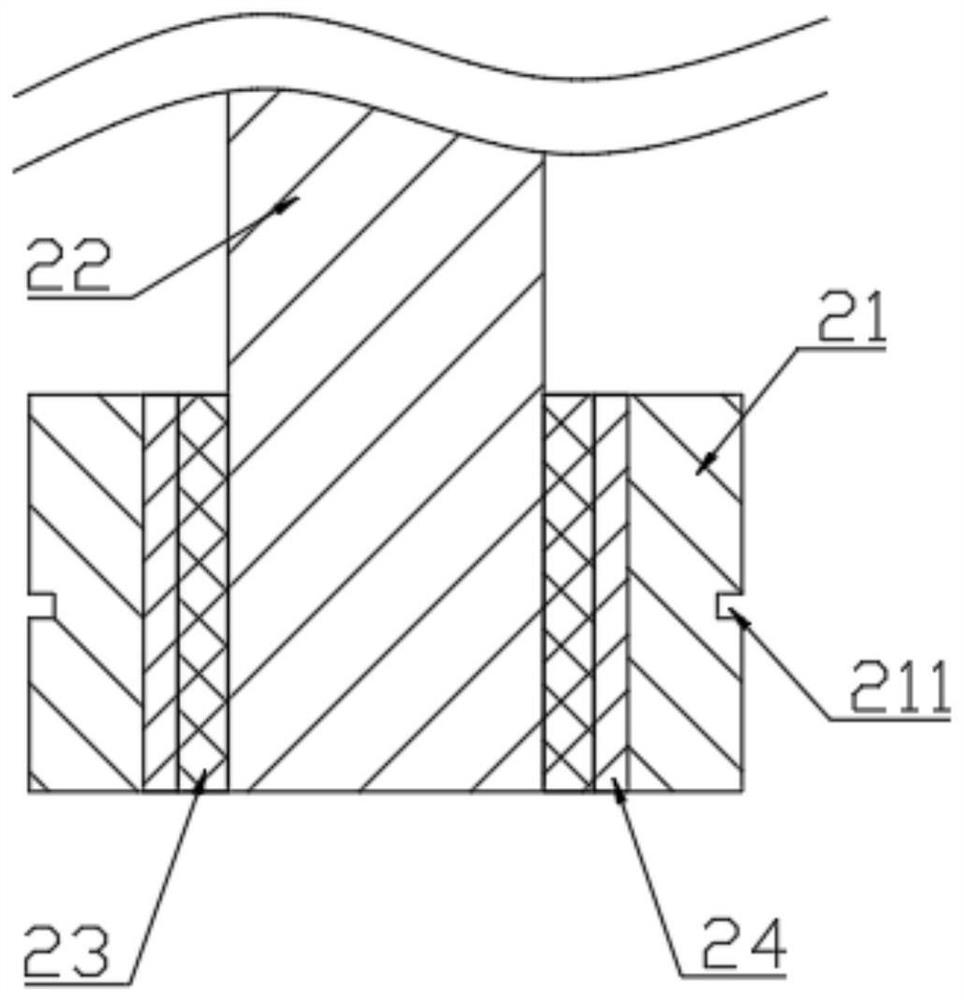

[0034] More specifically, the guide assembly includes guide rollers 21; the guide rollers 21 are rotatably arranged on the mounting base 10; the sides of each guide roller 21 are provided with second wire grooves 211 around their circumference;

[0035] More specifically, the guide assembly also includes a fixed shaft 22; the fixed shaft 22 is threadedly connected to the mounting base 10; the guide roller 21 is rotatably arranged on the fixed shaft 22;

[0036] More specifically, the guide assembly also includes a bearing 23 and a bearing bush 24; the bearing 23 is sleeved on the fixed shaft 22; the bearing bush 24 is sleeved outside the bearing 23, and the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com