Fatigue test clamp for bulkhead typical angular connecting pieces and using method

A technology for fatigue testing and connecting parts, which is applied in the direction of aircraft component testing, workpiece clamping devices, manufacturing tools, etc. It can solve problems such as slippage, camber deformation, and disappearance of clamping force, so as to reduce labor intensity, compact components, and facilitate loading and unloading. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

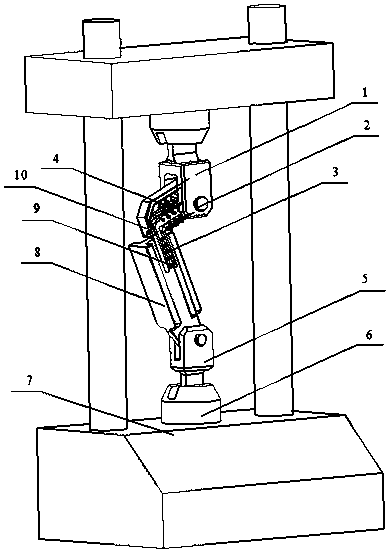

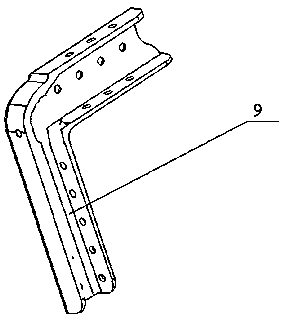

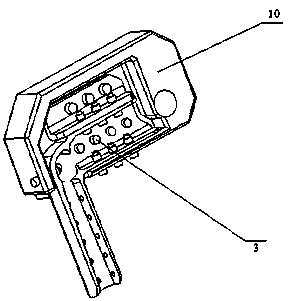

[0038] Such as Figure 1~8 Shown: A fatigue test fixture for typical angled connectors of bulkheads, including a fixed box body 10, a side plate 4, a lever 8 and a loading mechanism. The fixed box body 10 and the lever 8 are vertically connected (in an L-shape) The fixed box body 10 is fixedly connected from bottom to top with the horizontal part of the angle connecting piece 9 and the side plate 4, the side plate 4 includes a bottom surface and a side surface, one side of the horizontal part of the angle connecting piece 9 and the fixed box The side surface of the body 10 is fixedly connected, the other side of the horizontal part of the angle connector 9 is fixedly connected to the side surface of the side plate 4, and the bottom surface of the side plate 4 is fixedly connected to the bottom surface of the fixed box body 10; the lever 8 is provided with a groove, The vertical part of the angle connecting piece 9 is fixed in the groove; one side of the vertical part of the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com