A high reflectivity powder quantitative screening equipment

A screening equipment and high reflectivity technology, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve the problems of labor and time consuming, the screen is not stable enough, agglomeration, etc., and achieves easy removal and labor saving. , the effect of improving the screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

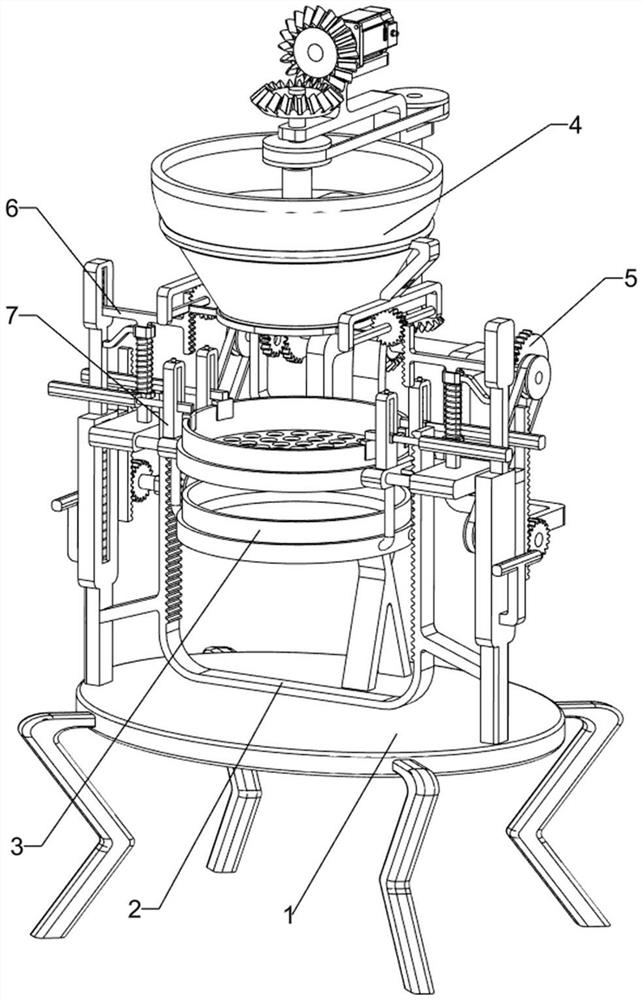

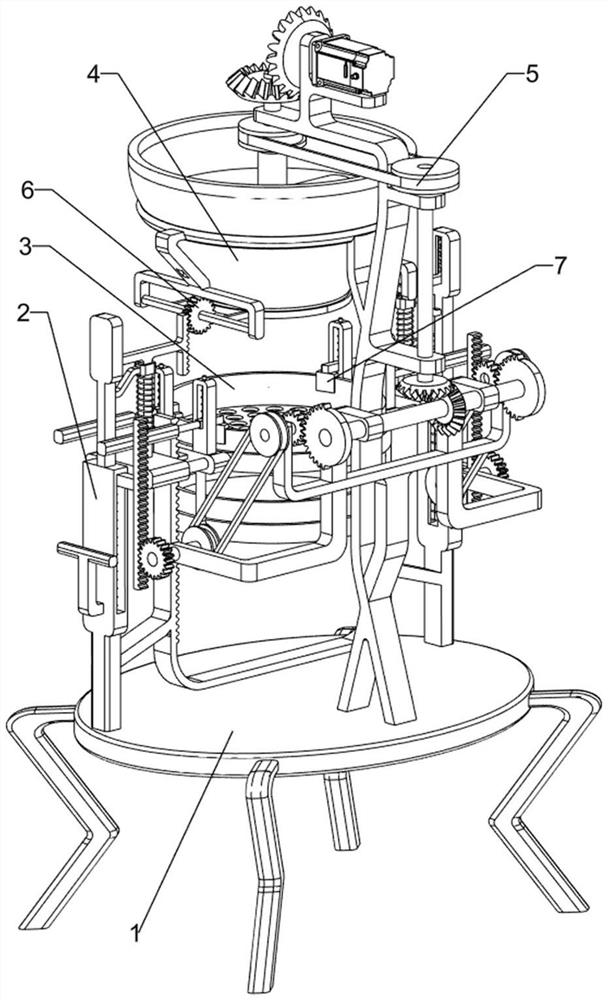

[0029] A high reflectance powder quantitative screening equipment, such as figure 1 , figure 2 and image 3 As shown, there is a base 1, the screening assembly 2, and the placing assembly 3, and the upper portion of the base 1 is provided with a screening assembly 2, and the upper portion of the screening assembly 2 is provided 3.

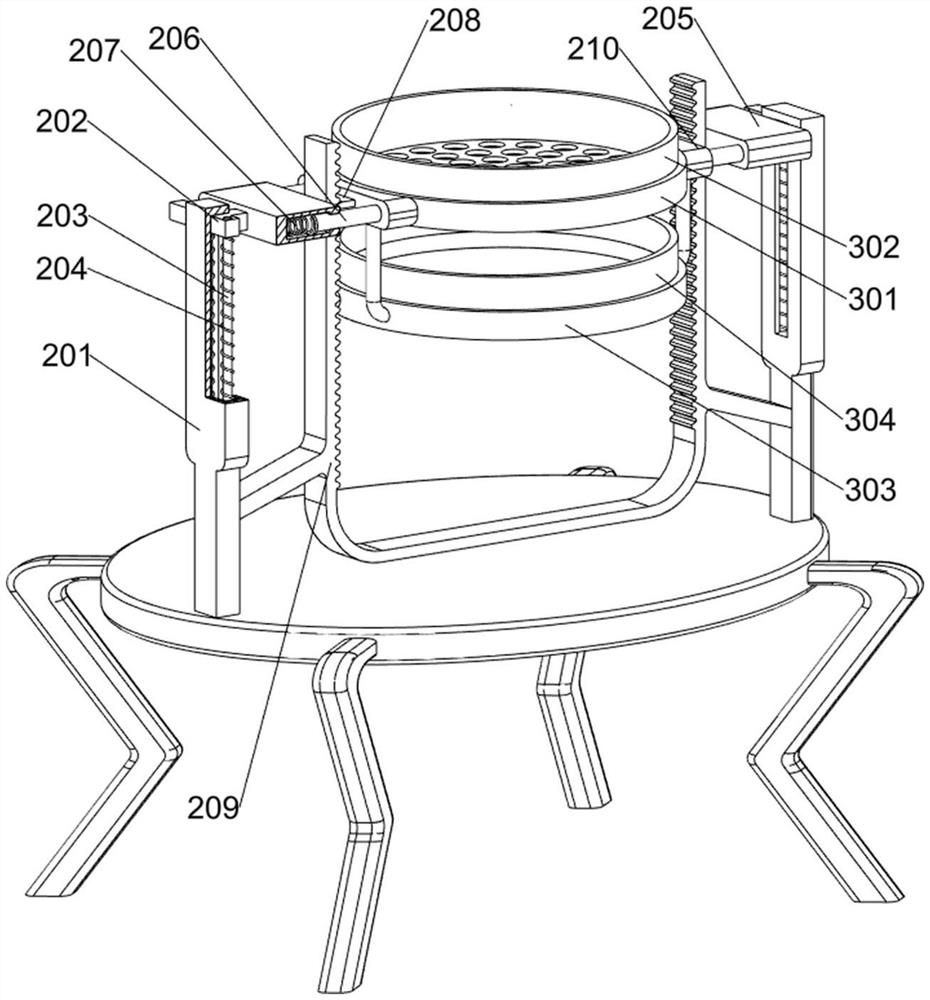

[0030]The screening assembly 2 includes a support slot 201, a slider 202, a first guide rod 203, a first spring 204, a first support slot 205, a first slider 206, a second spring 207, a block 208, a first tooth The strip 209 and the pump 210, the upper left side of the base 1 are connected to the upper left and right sides of the upper and lower sides of the support slot rod 201, and there is a first guide rod 203, and the two first guides are connected. Between the rod 203, the sliding block is connected to the slider 202, and the lower side of the slider 202 and the support slots 201 are connected to the first spring 204, and the first spring 204 is i...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it is also included, and the stirring assembly 4 is further included, the stirring assembly 4 includes a support frame 401, a servo motor 402, a first cone gear set 403, a stirring blade 404, a stirring frame 405, a support rod 406, a baffle 407, and a rotating shaft 408. The upper portion of the base 1 is connected to the support frame 401, and the upper portion of the upper front side of the support frame 401 is mounted, and the upper front side rotation of the support frame 401 is connected to the rotation shaft 408, the upper side and the servo motor 402 output the axis. A first cone gear set 403 is connected between the side, the central portion and the lower portion of the rotation shaft 408 are connected to the front side of the support frame 401, and the agitation frame 405 is attached to the front side of the support frame 401, and the stirring frame 405 is located outside the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com