Plastic raw material extrusion granulating device for chemical engineering

A technology for plastics and raw materials, applied in the field of extruding and granulating equipment for chemical plastic raw materials, can solve the problems of inconvenient use, different sizes of cutting particles, and inconvenient material receiving operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

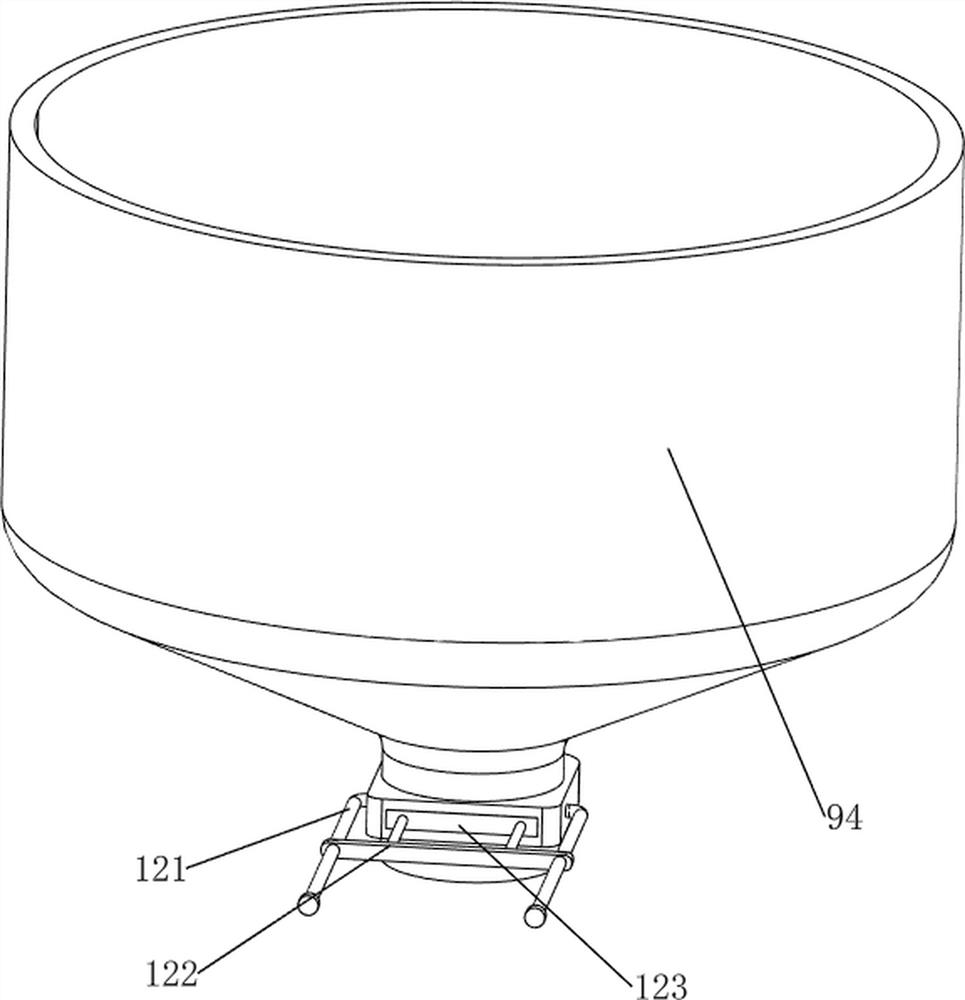

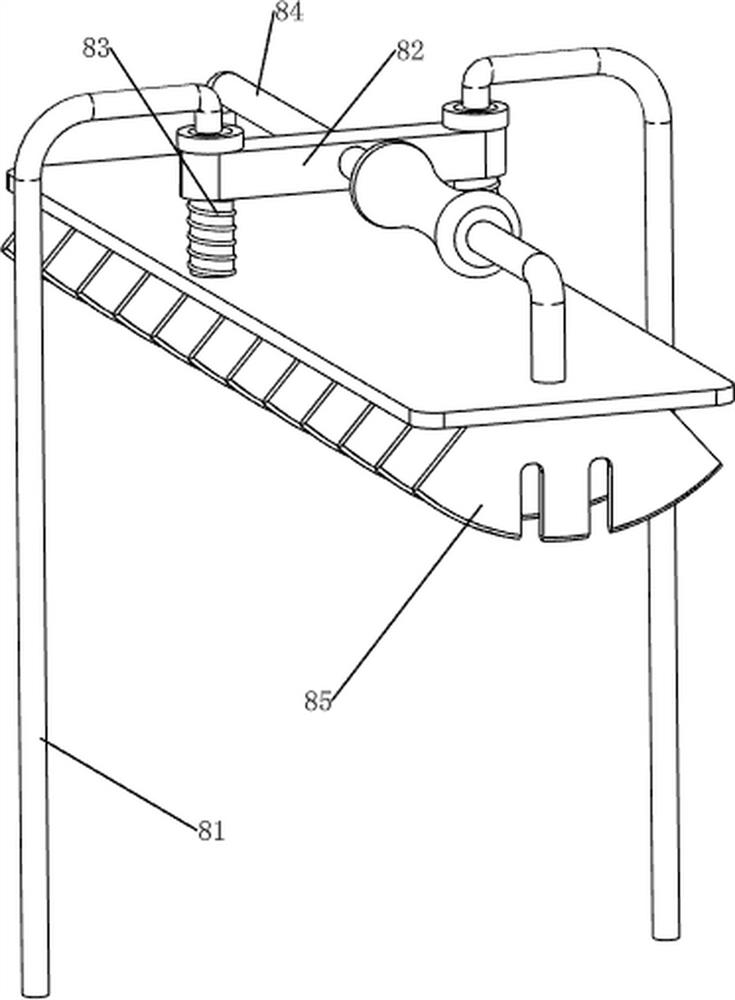

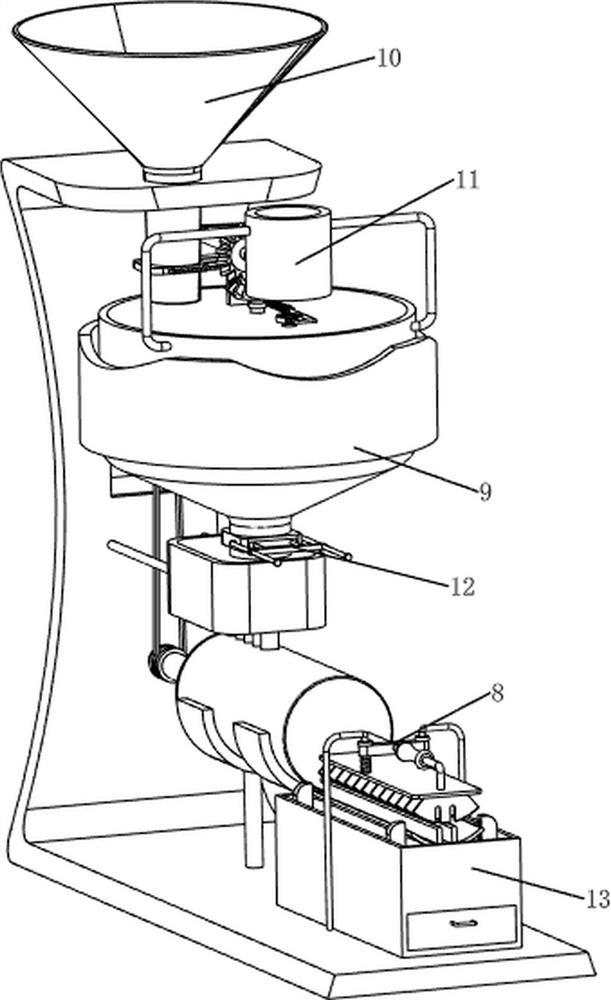

[0031] A kind of extruding granulation device of plastic raw material for chemical industry, such as Figure 1-6 As shown, it includes base plate 1, motor 2, first support rod 3, stirring shell 4, squeeze wheel 5, first rotating rod 6, first belt assembly 7, sovereign cutting 8 and stirring mechanism 9, the rear wall of base plate 1 A motor 2 is installed in the middle and upper part, a first support rod 3 is symmetrically arranged on the middle and rear part of the inner bottom of the bottom plate 1, a stirring shell 4 is arranged between the tops of the two first support rods 3, and a stirring shell 4 is rotated inside the stirring shell 4. Extrusion wheel 5, the rear end of extrusion wheel 5 is provided with a first rotating rod 6, the first belt assembly 7 is connected between the rear part of the first rotating rod 6 and the middle part of the output shaft of the motor 2, the upper middle front part of the inner bottom of the bottom plate 1 A sovereign cutting 8 is provid...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 7-10 As shown, a feeding mechanism 10 is also included, and the feeding mechanism 10 includes a loading hopper 101, a first baffle plate 102, a third support rod 103, a second spring 104, a first material baffle plate 105, and a second fixed plate 106 , the fourth rotating rod 107, the cam 108 and the third belt assembly 109, the upper rear side of the bottom plate 1 is provided with an upper hopper 101, the bottom opening of the upper hopper 101 is connected with the top of the loading hopper 93, and the lower part of the upper hopper 101 is provided with a first stop Plate 102, the front and rear sides of the first baffle plate 102 are symmetrically provided with third support rods 103, the first baffle plate 102 and the two third support rods 103 are slidingly provided with a first material blocking plate 105, and the third support rods 103 is surrounded by a second spring 104, the left and right ends of the second spring 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com