Test cake pressing device for concrete hollow block raw material experiment

A hollow block, experimental technology, used in manufacturing tools, ceramic molding machines, molding conveyors, etc., can solve the problems of unstable operation, affecting the accuracy of detection, affecting the pressing effect of pressing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

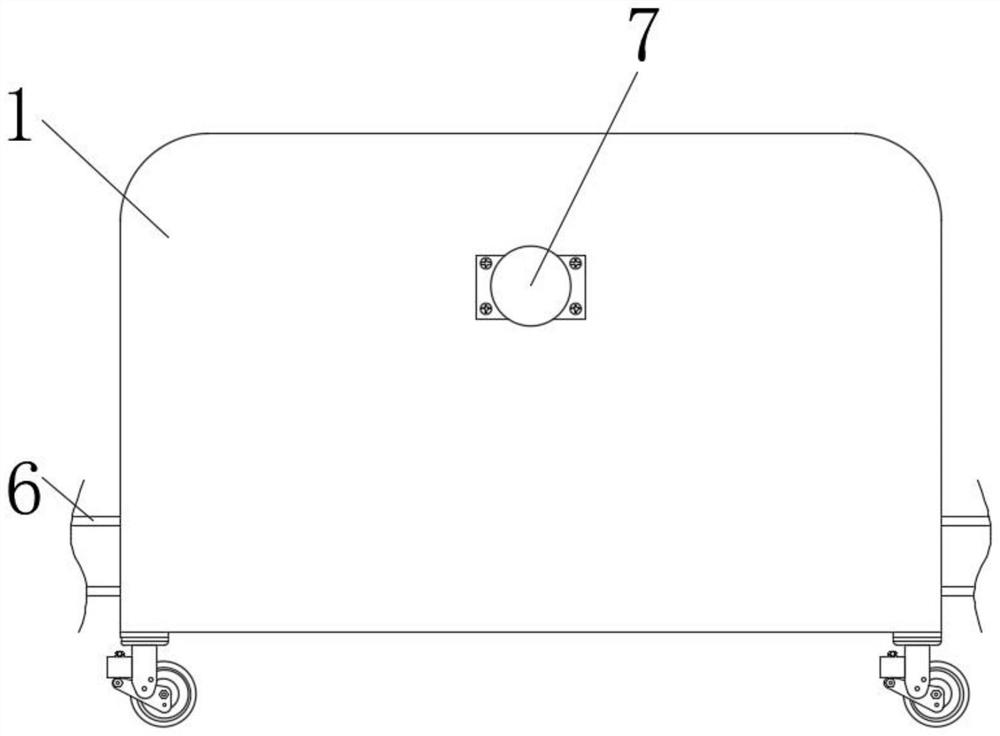

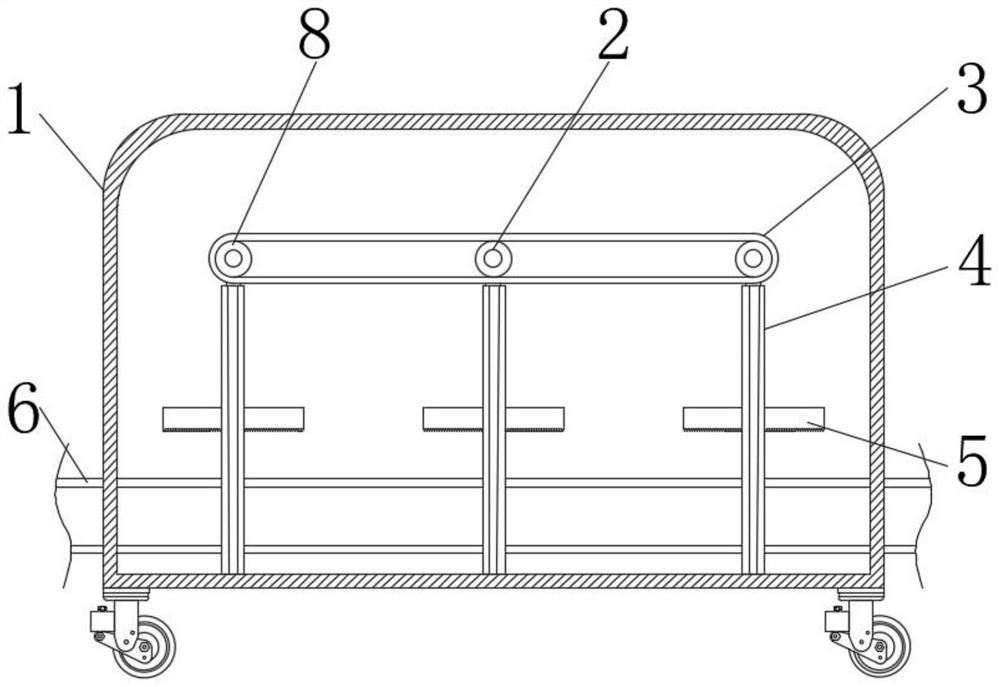

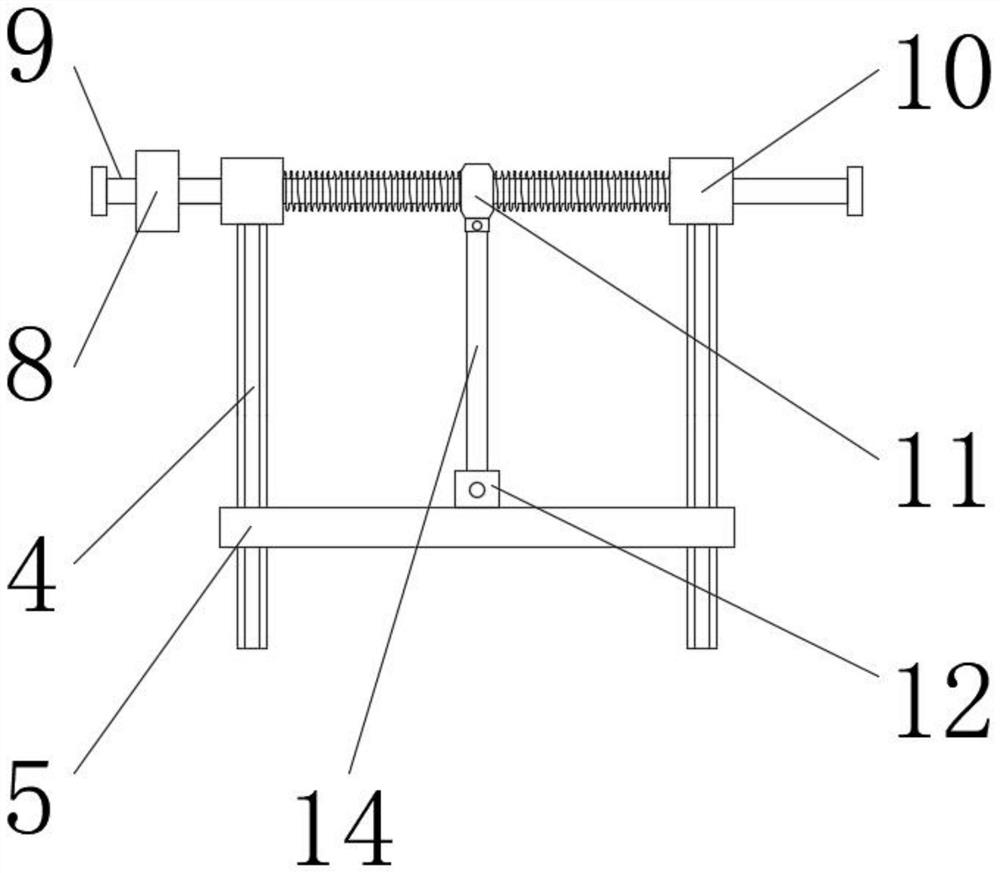

[0026] Such as Figure 1-4 As shown, the embodiment of the present invention provides a test cake pressing device for concrete hollow block raw meal experiment, which includes a processing box body 1, a mounting bearing 2, a material conveyor belt 6 and a servo motor 7, and the inside of the processing box body 1 is provided with multiple A transmission mechanism, a plurality of transmission mechanisms are arranged sequentially from left to right, the transmission mechanism includes a transmission threaded rod 9, the two ends of the transmission threaded rod 9 are rotatably connected with the inner side wall of the processing box body 1 through bearings, and the outer side of the transmission threaded rod 9 The positions near both sides of the surface are all rotatably provided with connecting and fixing cylinders 10, and the bottoms of the two connecting and fixing cylinders 10 are all fixedly connected with fixed installation frames 4, and the ends of the two fixed installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com