Knife rest of pencil sharpener

A pen sharpener and knife holder technology, applied in the field of stationery, can solve the problems of being thin, sharp and long, so as to withstand consumption, waste of resources, inconvenient use, etc. short length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

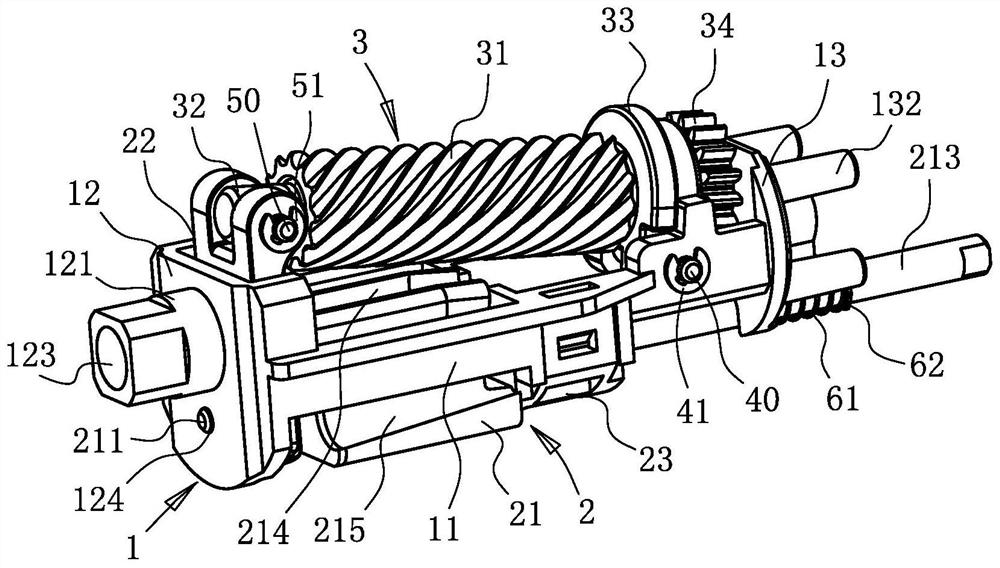

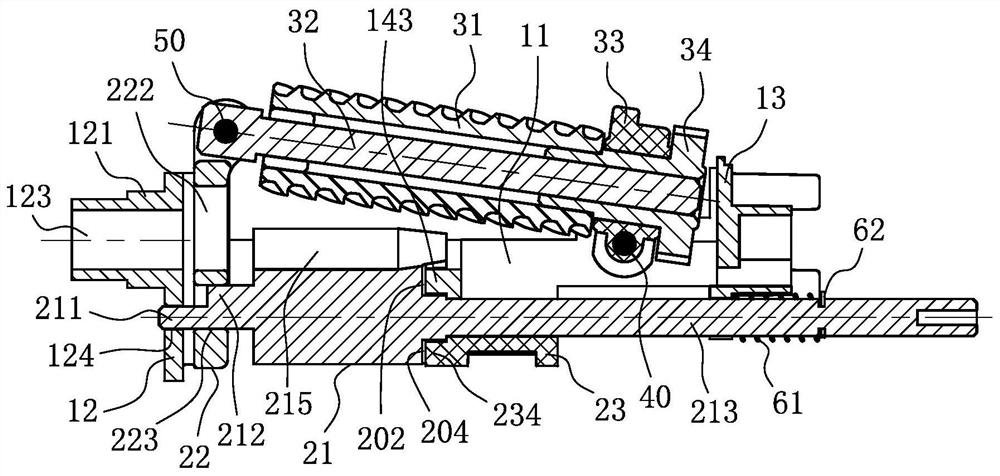

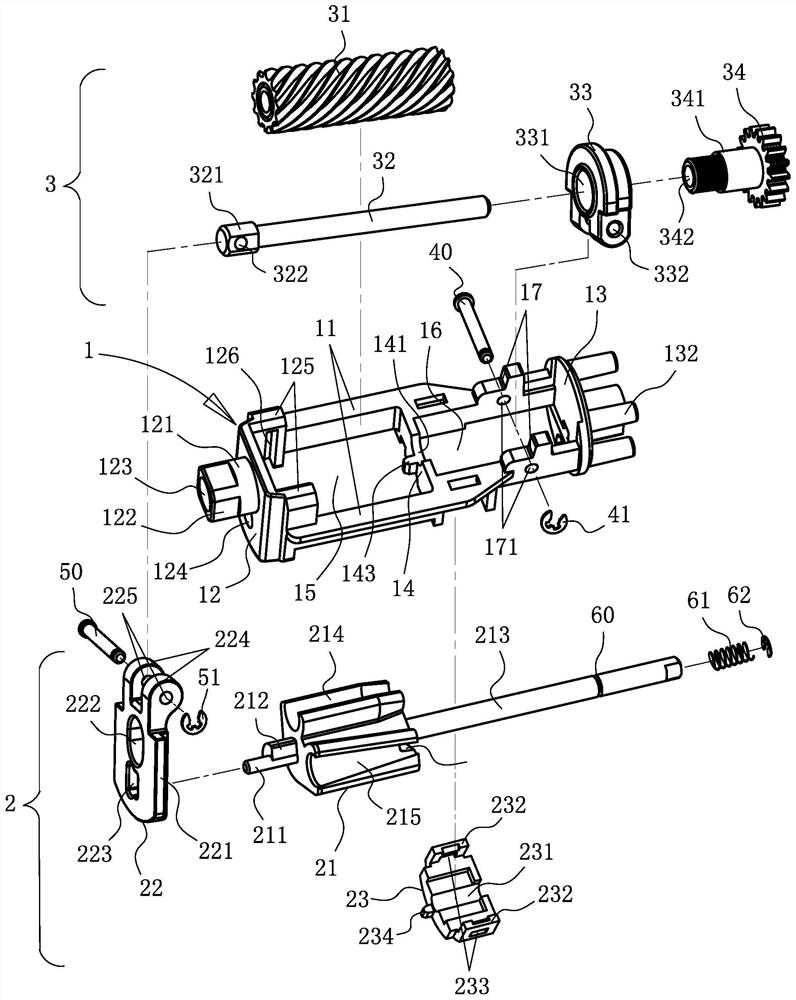

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0035] see Figure 1 to Figure 7 As shown, a knife holder for a pencil sharpener includes a knife holder seat 1, a pen holder assembly 2, and a hob assembly 3. It is characterized in that: the knife holder seat 1 includes two parallel symmetrical The support beams 11, the front ends of the two support beams 11 are provided with a front baffle plate 12, the rear ends of the two support beams 11 are provided with a rear baffle plate 13, and the middle part of the two support beams 11 is provided with a partition plate 14, and the front side surface of the partition plate 14 Between the inner surface of the front baffle 12 and the two side surfaces of the two support beams 11, a front inner cavity 15 is formed, which is straight up and down. A rear inner cavity 16 is formed between the surfaces of both sides; the axial width of the rear inner ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com