Rotation drive device

A technology of a rotary drive device and a rotary mechanism, which is applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems of falling, insufficient adsorption force, substrate falling, etc., and achieve the effect of suppressing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

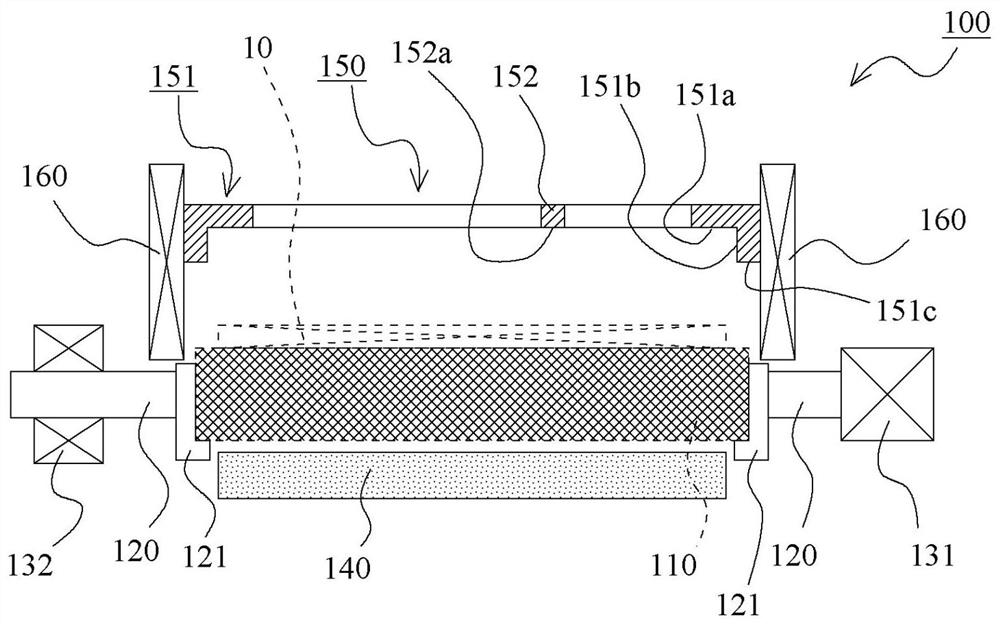

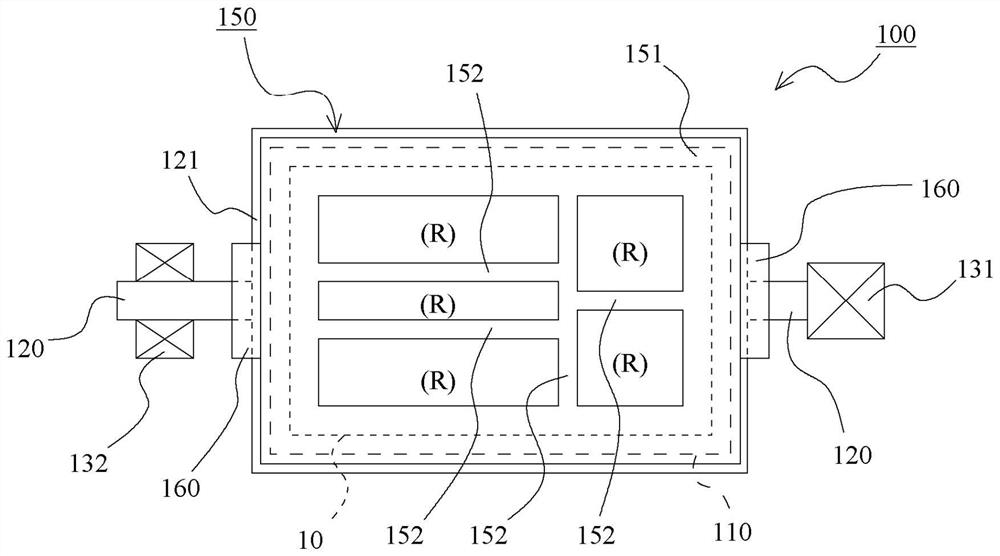

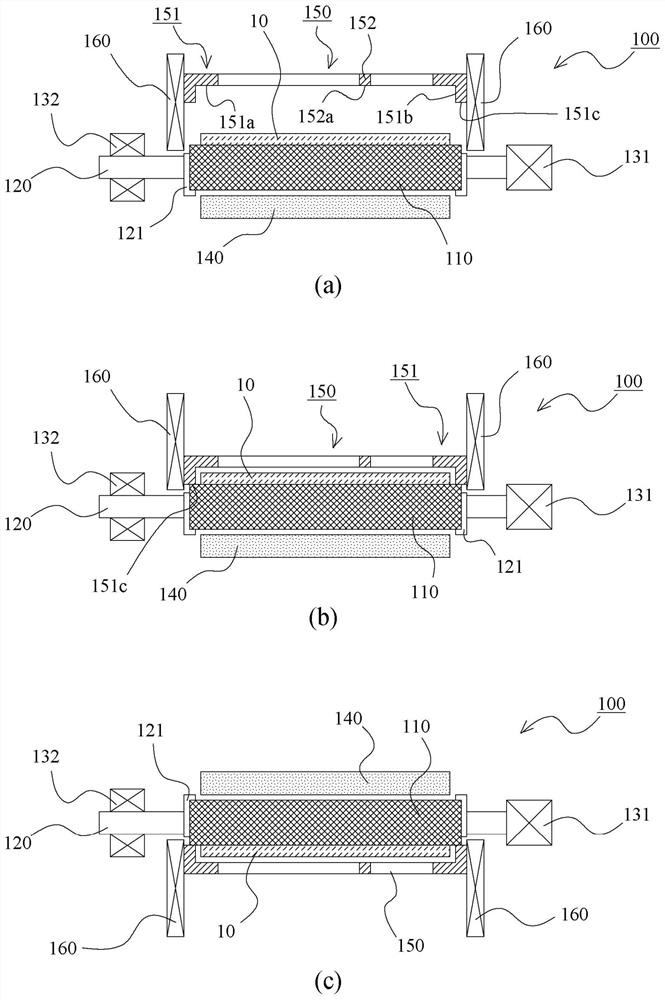

[0050] refer to Figure 1 to Figure 5 , the rotary driving device of Embodiment 1 of the present invention will be described. figure 1 It is a schematic configuration diagram of the rotary drive device according to the first embodiment of the present invention, and schematically shows the main configuration of the device when the device is viewed from the front. In addition, in order to facilitate understanding of the characteristics of each structure, the cross-section shows a part of the structure. figure 2 It is a schematic configuration diagram of the rotary drive device according to the first embodiment of the present invention, and schematically shows the main configuration of the device when the device is viewed from above. In addition, in order to facilitate the understanding of the arrangement relationship of the respective structures, some structures are shown in perspective with dotted lines. Moreover, in figure 1 and figure 2 In FIG. 2 , the carrier portion (...

Embodiment 2

[0073] Figure 6 and Figure 7 Example 2 of the present invention is shown. In the above-mentioned first embodiment, the structure in which a gap is ensured over the entire area between the substrate and the second facing surface of the outer peripheral frame portion in the state where the substrate is held by the carrier portion is shown, but in this embodiment , shows a structure in which a part of the gap is removed. The other basic structures and functions are the same as those in Embodiment 1, and therefore the same structural parts are assigned the same reference numerals and their descriptions are omitted.

[0074] Figure 6 It is a schematic configuration diagram of the rotary drive device according to the second embodiment of the present invention, and schematically shows the main configuration of the device when the device is viewed from above. In addition, in order to facilitate understanding of the arrangement relationship of each structure, some structures are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com