Prefabricated cabin door with double-sealing structure

A double-sealing and hatch technology, which is applied in the direction of sealing devices, windows/doors, building components, etc., can solve the problems of rainwater and dust entering and not being able to be effectively discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

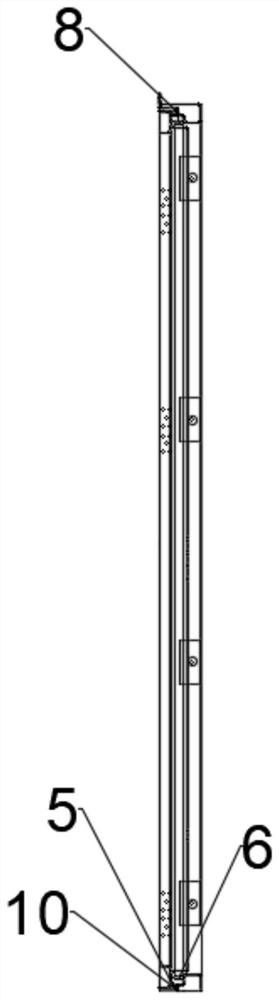

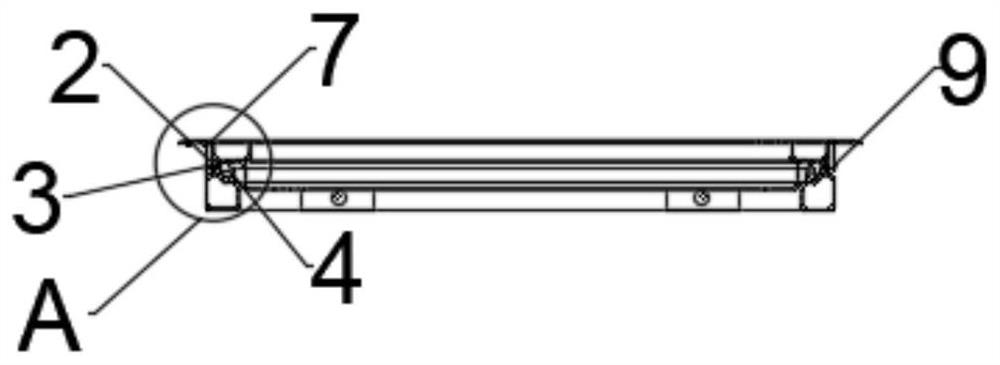

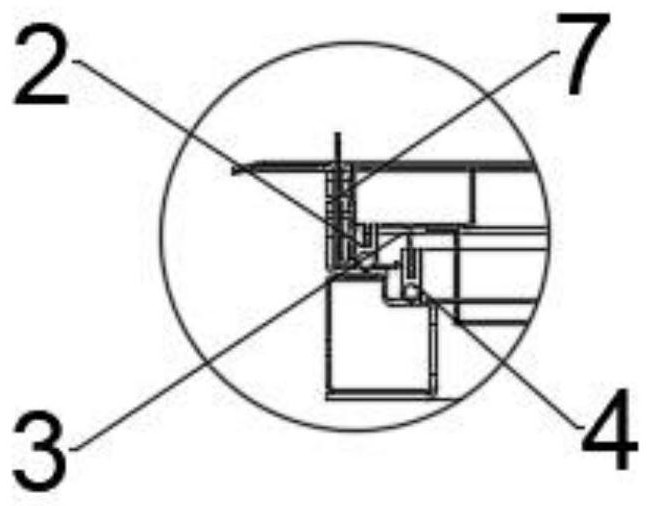

[0026] Such as Figure 1-4 As shown, this embodiment provides a prefabricated hatch with a double-seal structure, including: a hatch body 1, the hatch body 1 is arranged in the door frame, one side of the hatch body 1 is hinged in the door frame, and the door frame is provided with a ring setting There are a first sealing ring and a second sealing ring, the second sealing ring is arranged in the first sealing ring, and the corners of the first sealing ring and the second sealing ring are connected by a U-shaped flow guide groove 3 .

[0027] This application provides a prefabricated hatch with a double-seal structure, with double-layer sealing rings to protect the cabin from the impact of outdoor sand, dust or water layer by layer; when the hatch is closed, there will be sand or dust in the gap between the two sides of the hatch. Water enters and is discharged from the bottom of the door through the diversion groove 3, improving the protection level of the prefabricated cabin....

Embodiment 2

[0029] Such as Figure 1-4 As shown, this embodiment provides a prefabricated hatch with a double-seal structure, including: a hatch body 1, the hatch body 1 is arranged in the door frame, one side of the hatch body 1 is hinged in the door frame, and the door frame is provided with a ring setting There are a first sealing ring and a second sealing ring, the second sealing ring is arranged in the first sealing ring, and the corners of the first sealing ring and the second sealing ring are connected by a U-shaped flow guide groove 3 .

[0030] This application provides a prefabricated hatch with a double-seal structure, with double-layer sealing rings to protect the cabin from the impact of outdoor sand, dust or water layer by layer; when the hatch is closed, there will be sand or dust in the gap between the two sides of the hatch. Water enters and is discharged from the bottom of the door through the diversion groove 3, improving the protection level of the prefabricated cabin....

Embodiment 3

[0033] Such as Figure 1-4 As shown, this embodiment provides a prefabricated hatch with a double-seal structure, including: a hatch body 1, the hatch body 1 is arranged in the door frame, one side of the hatch body 1 is hinged in the door frame, and the door frame is provided with a ring setting There are a first sealing ring and a second sealing ring, the second sealing ring is arranged in the first sealing ring, and the corners of the first sealing ring and the second sealing ring are connected by a U-shaped flow guide groove 3 .

[0034] This application provides a prefabricated hatch with a double-seal structure, with double-layer sealing rings to protect the cabin from the impact of outdoor sand, dust or water layer by layer; when the hatch is closed, there will be sand or dust in the gap between the two sides of the hatch. Water enters and is discharged from the bottom of the door through the diversion groove 3, improving the protection level of the prefabricated cabin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com