Composite lithium membrane and lithium ion battery pole piece of diaphragm and preparation method thereof

A lithium-ion battery and lithium-composite technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as difficulty in engineering realization, complicated manufacturing process, and impact on energy density, and achieve improved winding Efficiency, reduced capacity loss, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

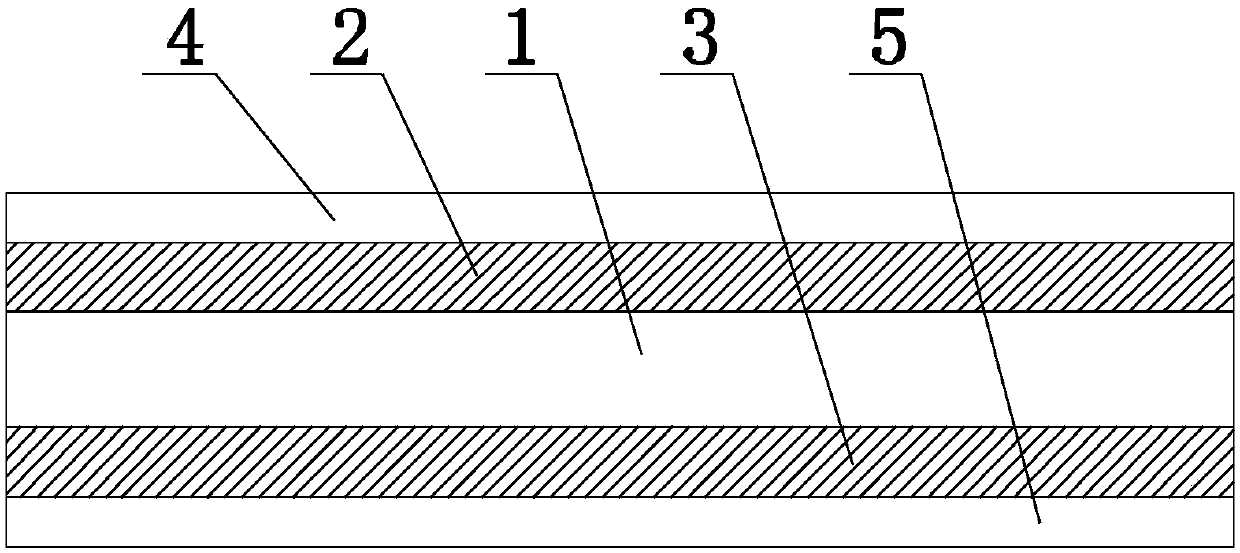

[0024] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a lithium-ion battery pole piece of a composite lithium membrane and diaphragm proposed by the present invention.

[0025] refer to figure 1 , a lithium-ion battery pole piece of a composite lithium film and diaphragm proposed by the present invention, comprising: a pole piece substrate 1, a first lithium film 2, a second lithium film 3, a first diaphragm 4, and a second diaphragm 5;

[0026] The first lithium film 2 and the second lithium film 3 are respectively covered on both sides of the pole piece substrate 1, the first diaphragm 4 is located on the side of the first lithium film 2 away from the pole piece substrate 1 and covers the first lithium film 2, and the second The diaphragm 5 is located on the side of the second lithium film 3 away from the pole piece base 1 and covers the second lithium film 3 .

[0027] In this example, the lithium-ion battery pole piece of the proposed compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com