Treatment method of acid-containing tail gas of chlorohydrination reaction

A treatment method and chlorohydrin technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of low economic efficiency, high investment in equipment and equipment, and treatment methods need to be improved. The overall investment of the device is small and the effect of reducing the investment cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

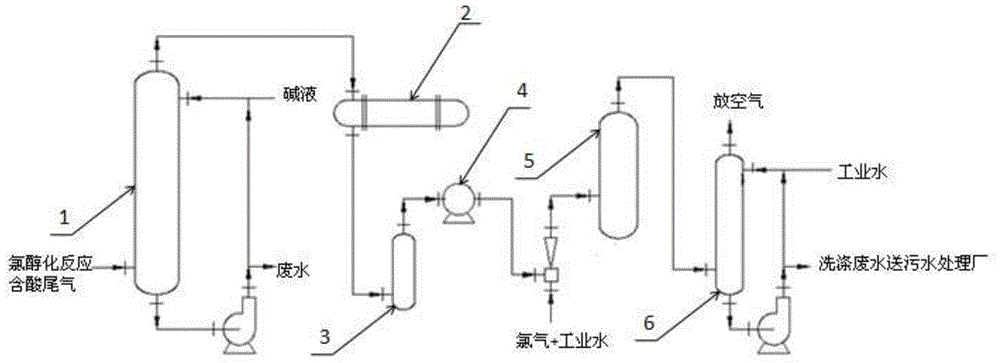

[0030] A treatment method for acid-containing tail gas of chlorohydrinization reaction in the production process of propylene oxide, comprising the steps of:

[0031] The acid-containing tail gas of the chlorohydrinization reaction (hydrogen chloride 15mol%, residual chlorine 6mol%, nitrogen 20mol%, propylene 16mol%) first passes through the alkali washing tower 1, and the material of the alkali washing tower 1 is FRP. The pump circulates the lye continuously, and the outlet of the circulating pump is set for pH detection. When the pH value of the liquid at the outlet of the pump is detected to be 7-8, the lye is replenished; after hydrogen chloride and residual chlorine are removed, the tail gas mainly contains propylene and nitrogen (nitrogen 40mol%, propylene 33mol%,), after circulating gas cooler 2 and gas-liquid separator 3 cooling, separation, gas phase component (propylene 44mol%), enters circulating gas blower 4 and carries out boosting to 200kPag, then with chlorine an...

Embodiment 2

[0033] A treatment method for acid-containing tail gas of chlorohydrinization reaction in the production process of propylene oxide, comprising the steps of:

[0034] Chloroalcoholization reaction acid-containing tail gas (hydrogen chloride 15mol%, residual chlorine 6mol%, nitrogen 20mol%, propylene 16mol%) first passes through the alkali washing tower 1, the material of the alkali washing tower 1 is carbon steel, the alkali liquor in the tower is excessive, and the tower bottom is set The circulating pump circulates the lye continuously, and the outlet of the circulating pump is set for pH detection. When the pH value of the liquid at the outlet of the pump is detected to be 7-8, the lye is replenished; after removing hydrogen chloride and residual chlorine, the tail gas mainly contains propylene, nitrogen ( Nitrogen 40mol%, propylene 33mol%), after circulating gas cooler 2 and gas-liquid separator 3 cooling, separation, gas phase component (propylene 44mol%), enters circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com