Ablation-resistant polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and composite materials, which is applied in the field of ablation-resistant materials, can solve the problems of easy ablation, high cost, and high production cost, and achieve good ablation resistance, good fluidity, and improved processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples, wherein the terms used in the examples are to describe specific embodiments, and do not constitute limitations to the protection scope of the present invention, wherein the raw materials used are A common commercially available product, so no specific restrictions on its source are required.

[0034] Basic embodiment

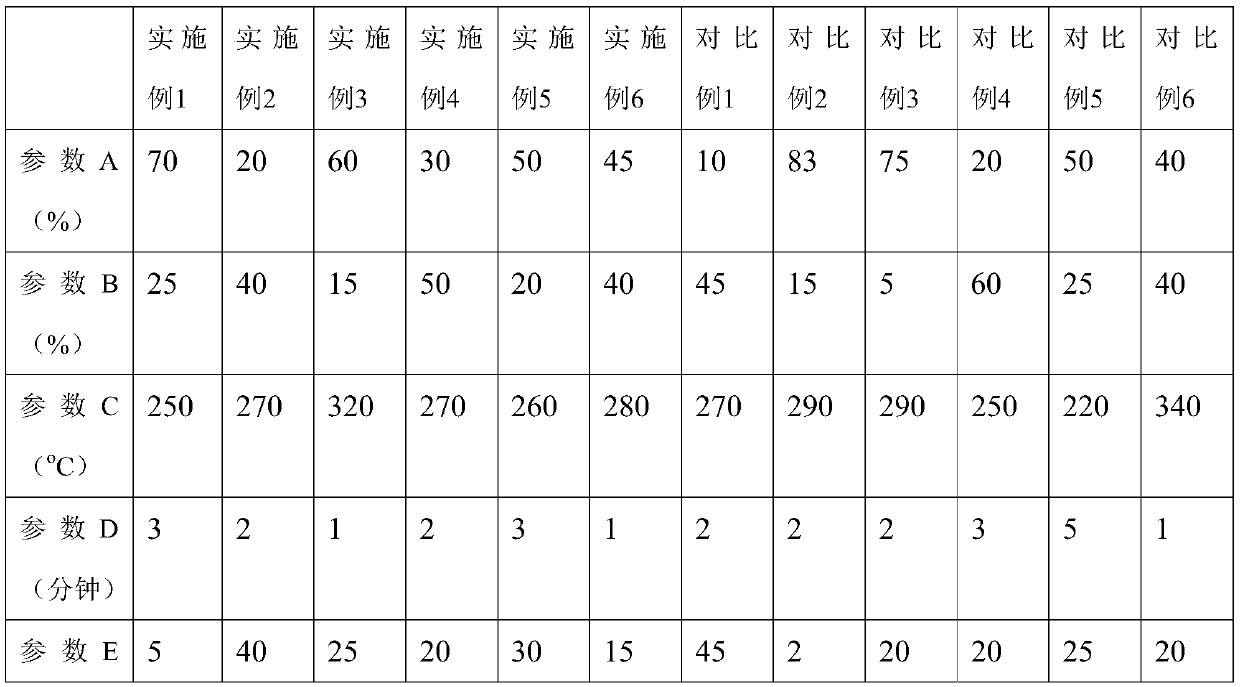

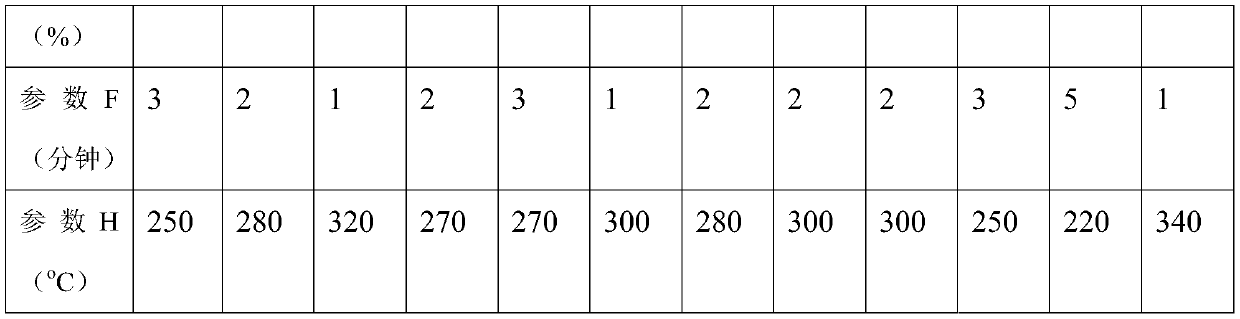

[0035] Different values of parameters in the basic embodiment constitute different specific embodiments, for example: parameters A, B, C, D, E, F, H, as shown in Table 1.

[0036] An ablation-resistant polyphenylene sulfide composite material and a preparation method thereof, wherein the polyphenylene sulfide composite material includes the following raw materials: polyphenylene sulfide resin, alkali-free long glass fiber and poly-m-xylylene adipamide;

[0037] The preparation method of the ablation-resistant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com