Hydraulic anchoring test device and method

A test device, anchoring technology, applied in earthwork drilling, wellbore/well components, measurement, etc., can solve the problem of how to test the sealing performance, etc., to achieve easy implementation, promote more effective implementation, broad development space and application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The examples given below are specific descriptions of the present invention, and it is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention.

[0032] The descriptions referring to "first", "second", "third", "fourth", "fifth", etc. in the present invention are for descriptive purposes only, and shall not be construed as indicating or implying their relative importance or The number of technical characteristics indicated is implied. Thus, a feature defined as "first", "second", "third", "fourth", "fifth" may explicitly or implicitly include at least one of such feature.

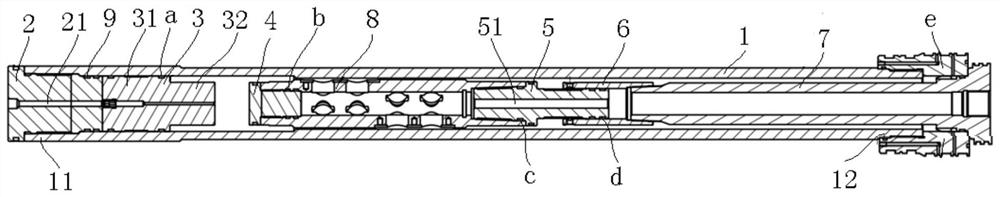

[0033] figure 1 An embodiment of a hydraulic anchoring test device among numerous embodiments of the present invention is shown as an example. The hydraulic anchoring test device includes a test casing 1 , a plug 2 , a piston 3 , a blocking member 4 , a telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com