Method for extracting goaf gas through top plate high-position comb-shaped drill holes

A high-level, comb-shaped technology, which is applied in the field of goaf gas extraction by high-level comb-shaped drilling on the roof, can solve problems such as potential safety hazards, unevenness, and waste of financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

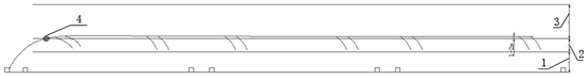

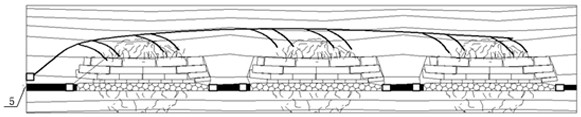

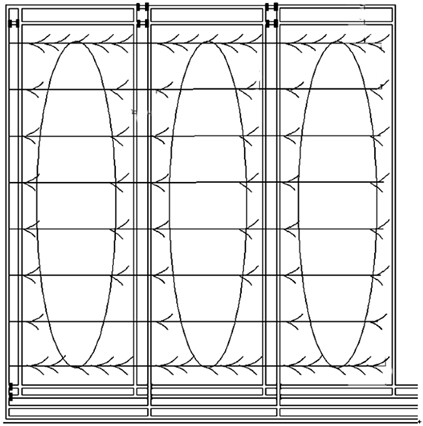

[0021] The layout of high-level comb-shaped drilling holes on the roof is as follows: Figure 1-Figure 3 As shown, this method mainly consists of the location of the drill hole (both sides of the roadway in the mining area or the roadway along the channel), the direction of the drill hole (along the stratum inclination), the layout of the horizontal section of the main hole (in the curved subsidence zone), the main hole Length (covering two or more coal mining faces), main hole spacing (60-80m), branch hole horizon (middle and lower part of coal seam roof fissure zone), branch hole spacing, branch hole length (covering both sides of the main hole 10- 20m range), the position of the end hole of the branch hole (located within the "O" ring) and other 9 parts.

[0022] The specific construction of high-level comb-shaped drilling on the roof is divided into the following steps, as follows: Figure 1-Figure 3 Shown:

[0023] In the first step, the borehole tracking design method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com