A valve device with the functions of high-pressure low-speed oil injection and high-pressure high-speed oil discharge

A high-speed, valve device technology, applied in the direction of non-mechanical drive clutches, clutches, fluid-driven clutches, etc., can solve the problems of difficult design and processing of rotary seals, and the inability to realize oil filling and draining of rotary seals, so as to reduce design and processing effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

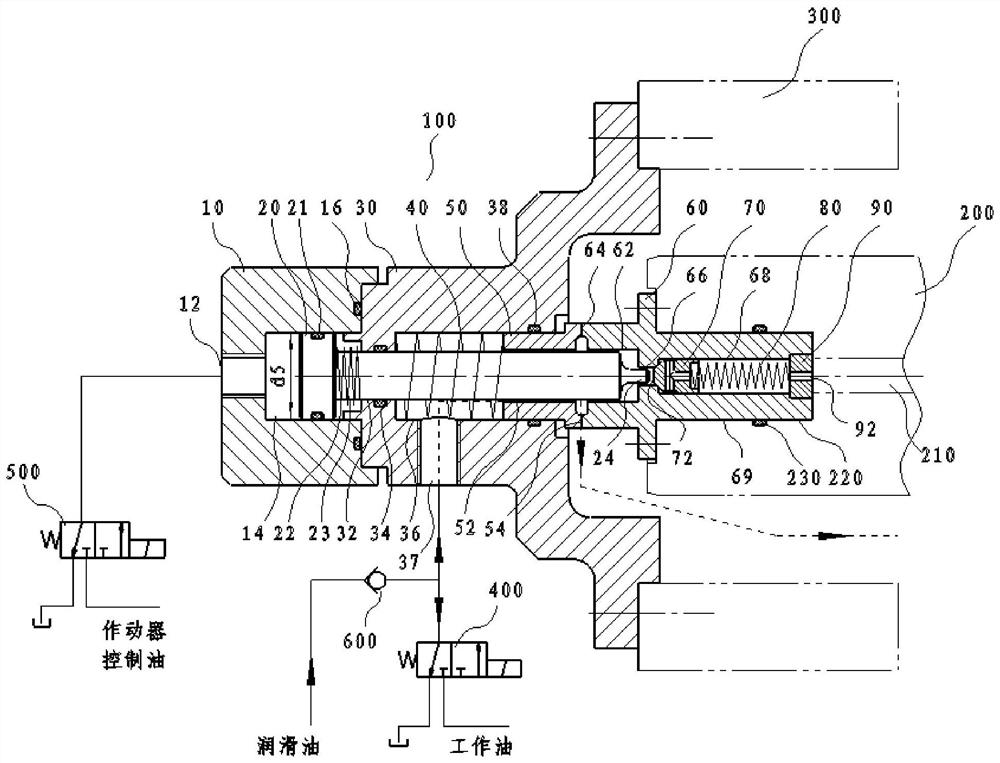

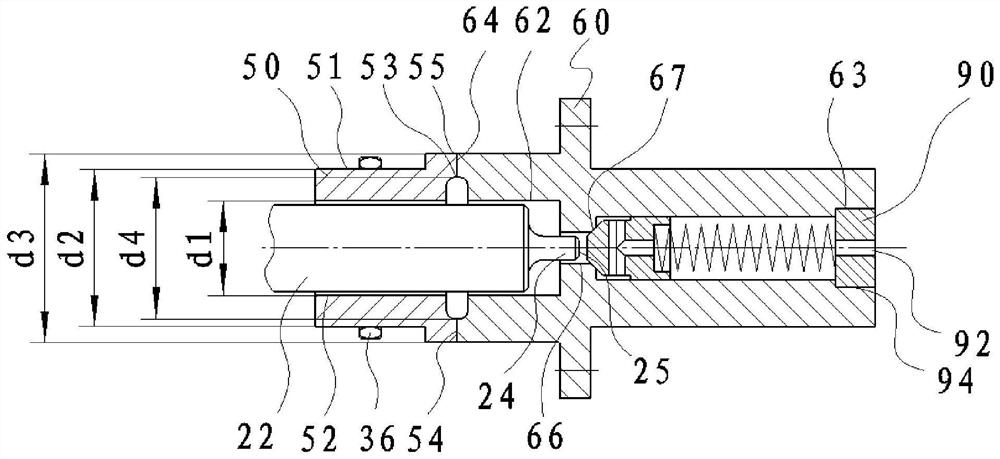

[0024] combine Figure 1-8 , the friction clutch rotary cylinder with micro-leakage or zero-leakage characteristics is rigidly installed on the connecting shaft 200, the connecting shaft 200 is supported on the support housing 300 through bearings, and the connecting shaft 200 rotates with the rotary cylinder. The core of the connecting shaft 200 is an oil passage 210, and the oil passage 210 communicates with the rotary oil cylinder. At the end of the connecting shaft 200, the actuator cylinder 10, the piston 20, the piston rod 23, the ejector rod 24, the adapter plate 30, the sealing spring, the rotary sealing static ring, the one-way valve body 60, the one-way valve core 70, The one-way valve spring 80 and the one-way valve spring baffle 90 are concentrically arranged and mechanically connected in sequence.

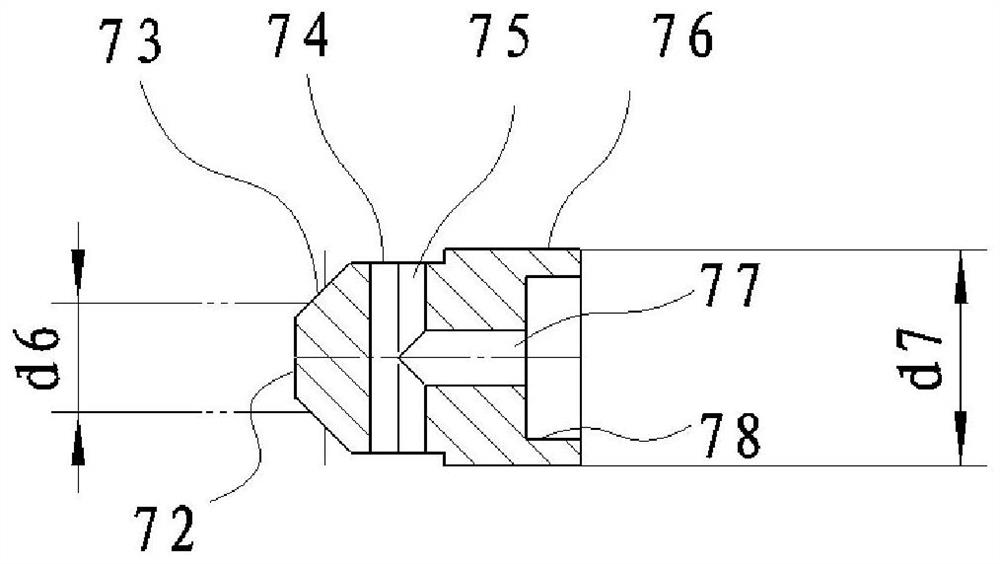

[0025] The one-way valve mounting hole 220 formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com