Welding system and welding method for friction stir welding

A technology of friction stir welding and welding system, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as poor mechanical properties of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

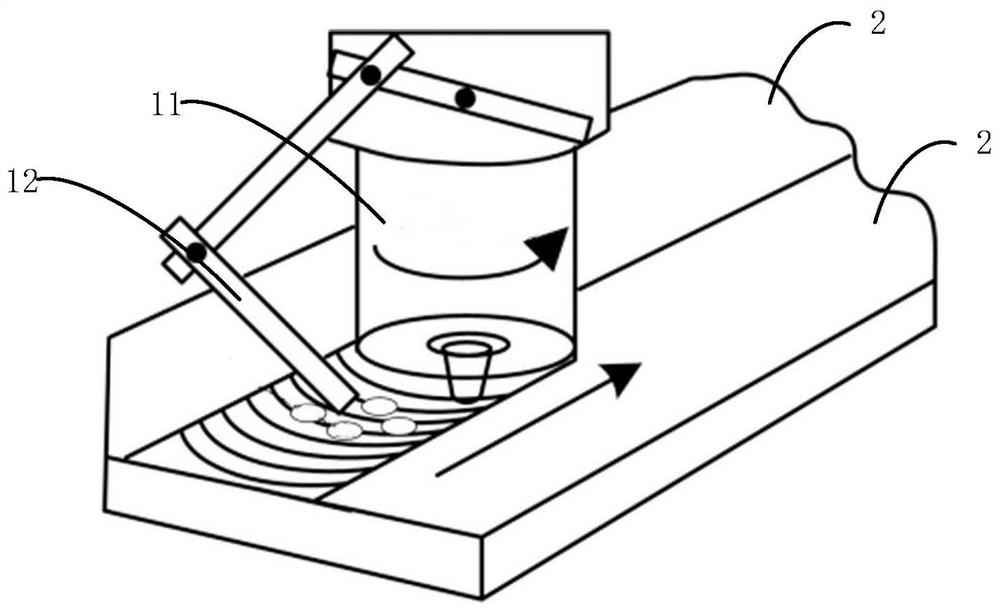

[0021]figure 1A schematic diagram of a welding system for stirring friction welding according to the embodiment of the present application.

[0022]Such asfigure 1As shown, the welding system of stirring friction welding of the present invention, including:

[0023]The stirring head 11 is used to weld both the bonded base material 2 to form weld;

[0024]The cooling device is used to cool the weld during welding.

[0025]The welding system of the stirring friction welding is carried out in the agitating head, and the cooling device is lowered by the weld to prevent or reduce the weld to form an intermetallic compound at the weld by cooling. However, there is less distribution of crispy phase, and the mechanical properties of the weld joint are high.

[0026]Among them, iffigure 1As shown, the arrow on the stirring head represents the direction of rotation of the stirovery head, and the arrow on the base material to be welded represents the welding direction.

[0027]In implementation, the welding sys...

Embodiment 2

[0064]The welding method of stirring friction welding in the present application embodiment, using an example of stirring friction welding system, including the following steps:

[0065]While welding at the stirring head, cooling is performed at the weld.

[0066]The welding method of stirring friction welding is carried out in the agitating head, and the weld is cooled when the blender is welded to form a weld. Avoid or reduce the formation of intermetallic compounds at a weld by cooling, thereby having a small distribution of brittle phase, and the mechanical properties of the weld joint are high.

[0067]In the implementation, the step of cooling the weld when the blender to be welded is formed, and the weld is used to cool the weld, including:

[0068]Get the perceived temperature of the temperature sensor, transmit the perceptual temperature of the temperature sensor to the cooling device;

[0069]According to the perceptual temperature of the temperature sensor, the cooling device controls t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com