Welding software module in welding device

A welding software and welding device technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of poor stability, excessive dust, affecting the operator to view the display content of the display, etc., to avoid the influence of dust, stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

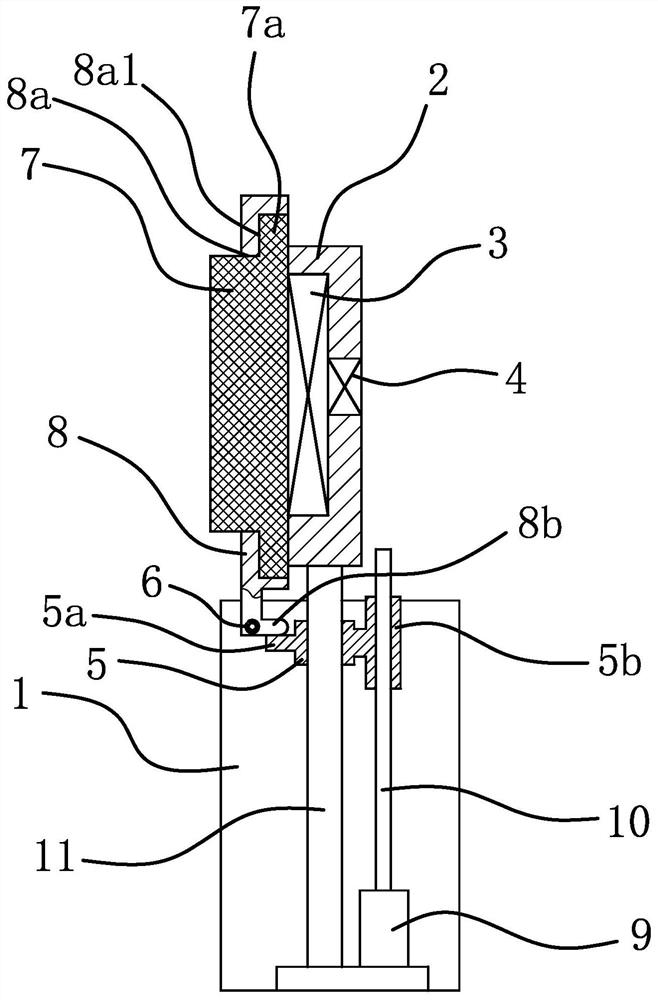

[0026]Such asfigure 1As shown, the welding device includes a frame 1 and a welding software module connected to the rack 1.

[0027]The welding software module in this welding device includes a substrate 2, a display screen 3, and a receiver 4 for receiving the welding process information. The substrate 2 is fixed to the rack 1 by the link 11, and the display screen 3 is inherently in the substrate. On the side of the 2nd side, the receiver 4 is inherently connected to the other side of the substrate 2, and the receiver 4 is connected to the display screen 3 and the display screen 3 can display the welding process information received at the receiver 4, and the link 11 is also The connection with the slider 5 that can be translated, has a driving member capable of driving the slider 5, and the frame 1 hinges the cover plate 8, the cover 8 and the hinged portion of the frame 1 have twists The spring 6 is a tendency to carry on the substrate 2 and hold the display screen 3 in the elastic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap