Cable fault detection equipment

A technology for cable fault detection equipment, which is applied to the fault location, components of electrical measuring instruments, fault detection by pulse reflection method, etc. It can solve the problems of inconvenient replacement of internal modules and inability to realize comprehensive cable fault detection, etc. To achieve the effect of convenient post-analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

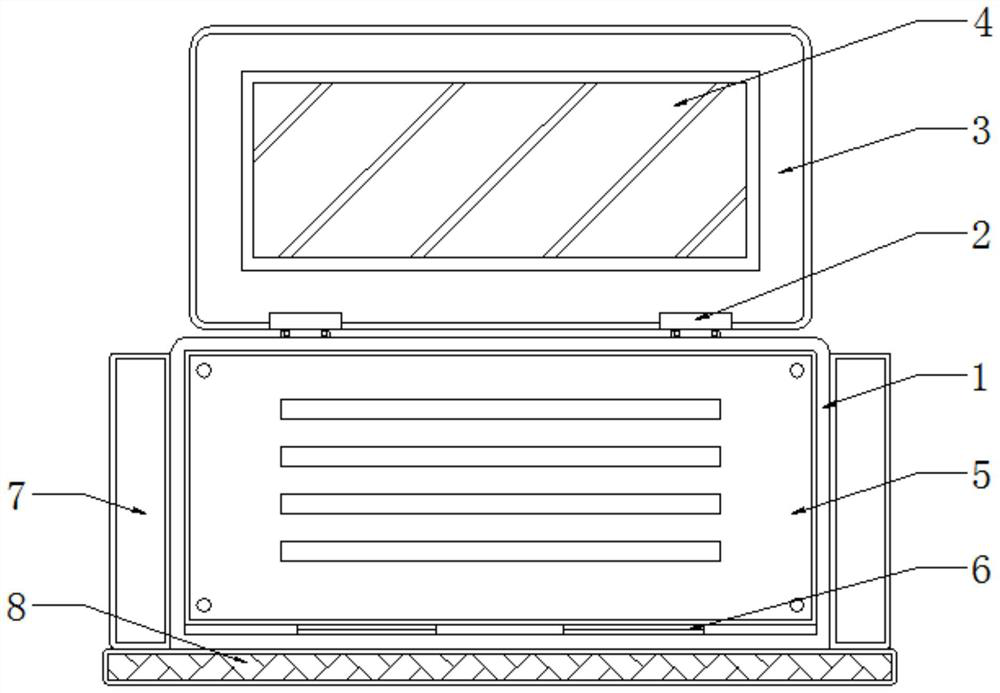

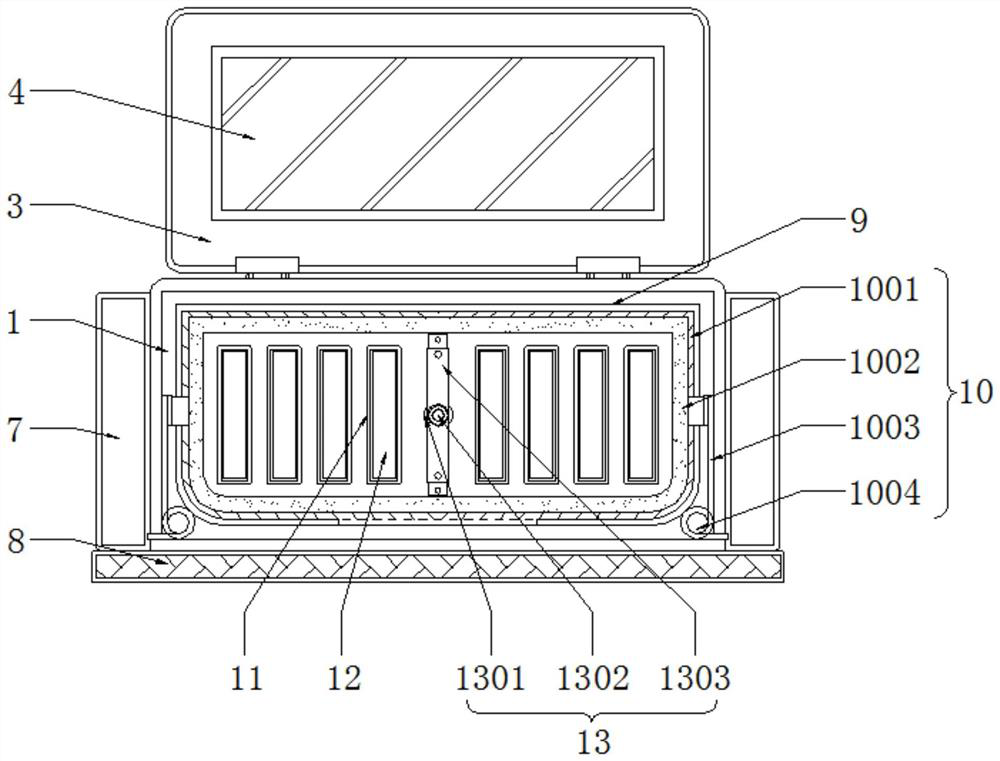

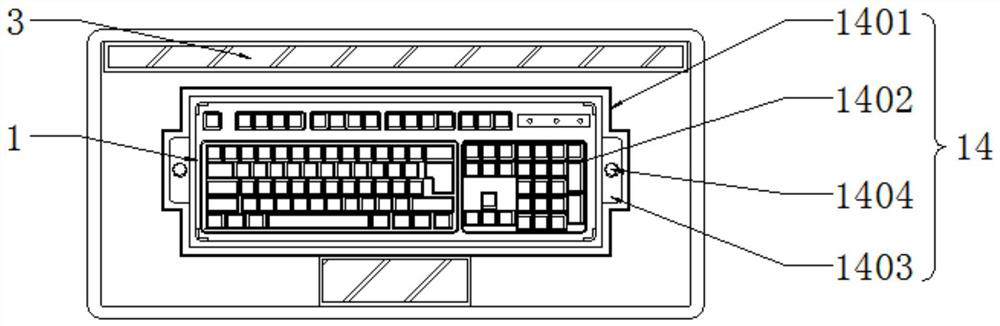

[0032] see Figure 1 to Figure 5 , the present invention provides a technical solution: a cable fault detection device, comprising a device body 1 and a plug slot 11, an upper cover 3 is installed above the equipment body 1 through a hinge 2, and a display is installed on the inner side of the middle of the upper cover 3 Screen 4, an installation frame 9 is arranged on the front inner side of the equipment body 1, and a protective assembly 10 is arranged on the inner side of the installation frame 9. The protective assembly 10 includes a rubber layer 1001, a flexible airbag layer 1002, an inflation tube 1003 and a micro air pump 1004, and the rubber The inner side of the layer 1001 is fixed with a flexible airbag layer 1002 , an inflatable tube 1003 is connected to the outer middle side of the flexible airbag layer 1002 , and a micro air pump 1004 is installed at the lower end of the inflatable tube 1003 , and the insertion slot 11 is opened inside the installation frame 9 . ,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap