Wear-resistant ceramic ring surface fine grinding equipment and fine grinding method for electrical equipment

A technology for wear-resistant ceramics and electrical equipment, which is applied in metal processing equipment, chemical instruments and methods, grinding/polishing equipment, etc., and can solve the problem of incomplete grinding of details of wear-resistant ceramic rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

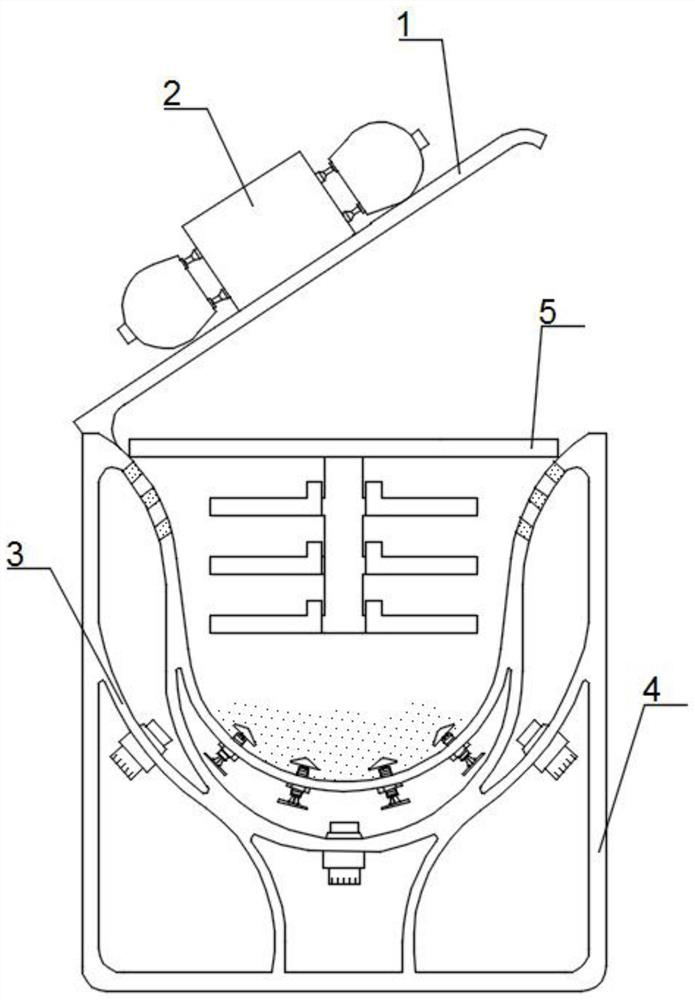

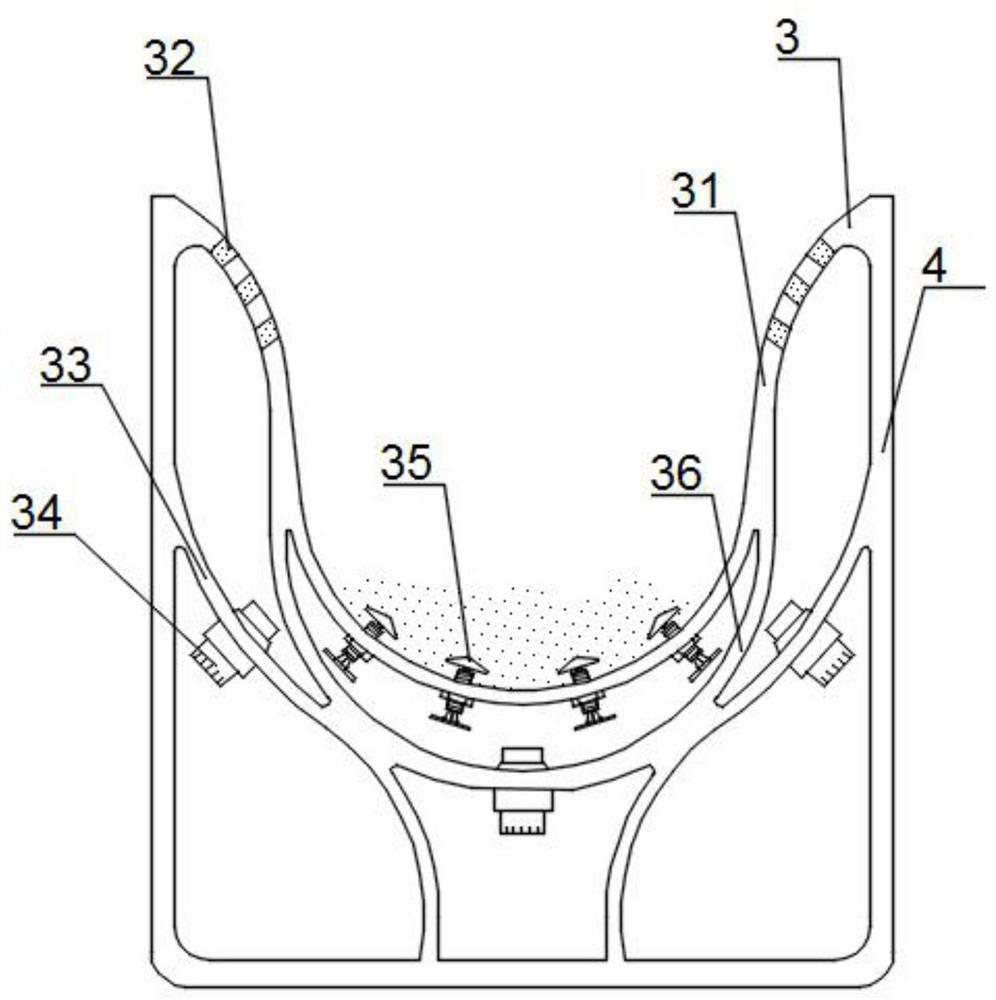

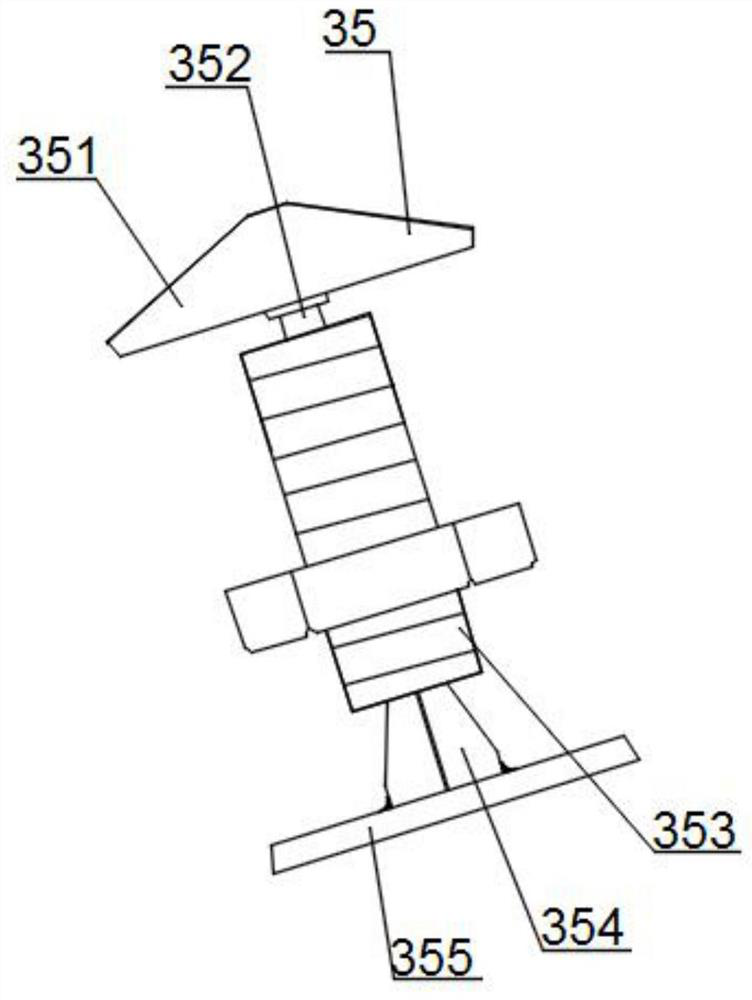

[0034] such as Figure 1-9 As shown, the wear-resistant ceramic ring surface grinding equipment for electrical equipment includes a container 4 and a top cover 1, the top cover 1 is arranged above the container 4, and the top cover 1 is rotatably connected to the container 4; The top end of the top cover 1 is connected with the filter assembly 2 through, the container 4 is provided with a hooking assembly 5, and a fine grinding assembly 3 is integrally formed under the hooking assembly 5 in the container 4; The refining assembly 3 comprises a U-shaped container 31, which is fixed at the port in the container 4, and the surface of the U-shaped container 31 is provided with air holes 32 in an annular distribution pattern near the junction. A bowl-shaped container 36 is fixed at the bottom of the U-shaped container 31, a cavity is arranged between the bowl-shaped container 36 and the U-shaped container 31, and a plurality of spray structures 35 are arranged in the cavity at the wall o...

Embodiment 2

[0040] such as Figure 1 、 5 And 6, the hanging assembly 5 comprises a hanging plate 51, a hanging rod 52, a limiting structure 53 and a hanging ring 54, the hanging plate 51 is arranged above the refining assembly 3 at the port of the container 4, and the hanging plate 51 is hung to the refining assembly 3; Three hanging rings 54 are arranged below the hanging plate 51, hanging rods 52 are arranged between the hanging rings 54 at vertical positions, the hanging rods 52 are connected with the hanging plate 51, and the three hanging rings 54 are fixed to the hanging rods 52 at equal intervals; The end of the hanging ring 54 is connected with a vertical limiting head, four limiting structures 53 are arranged at the hanging ring 54, and the limiting structures 53 are sleeved at the hanging ring 54; The limiting structure 53 includes a button 531, a sleeve 532, an elastic piece 533 and a Y-shaped thin plate 534. The sleeve 532 is sleeved at the hanging ring 54, and the elastic piece 53...

Embodiment 3

[0044] such as Figure 1 、 78 and 9, the filter assembly 2 comprises a magnetic impeller 21, an exhaust pipe 22, a peeling plate 23, an impact structure 24 and an air bag 25, wherein the exhaust pipe 22 penetrates and is fixed to the top end of the top cover 1, and the exhaust pipe 22 is transversely provided with the magnetic impeller 21, both ends of which are inserted into the wall of the exhaust pipe 22, and the magnetic impeller 21 is rotatably connected into the exhaust pipe 22; The magnetic impeller 21 is provided with a peeling disk 23, and the peeling disk 23 is sleeved at the magnetic impeller 21; The left and right sides of the row tube 22 are provided with air bags 25, and the inner side of the air bags 25 is symmetrically connected with an impact structure 24, and the impact structure 24 penetrates into the row tube 22; The nozzle of the impact structure 24 points to the peeling plate 23; The impact structure 24 includes an air pipe 241, a piston 242, a sleeve plate 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com