Chemical raw material crushing and grinding device

A grinding device and chemical raw material technology, applied in the direction of drying gas arrangement, dryer, grain processing, etc., can solve the problems of slowing down the production efficiency of the factory, easy occurrence of continuous wires, sticking, and lower qualified rate of raw materials, so as to avoid The effect of grinding is not good, easy to dry, and convenient to grind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

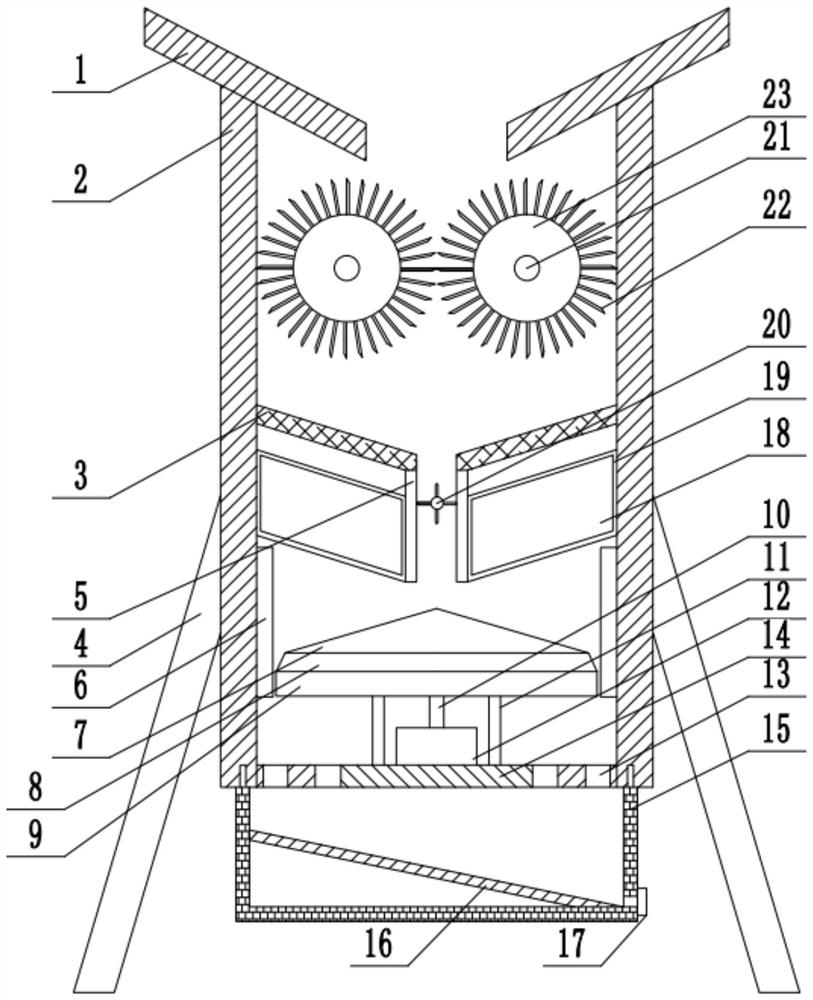

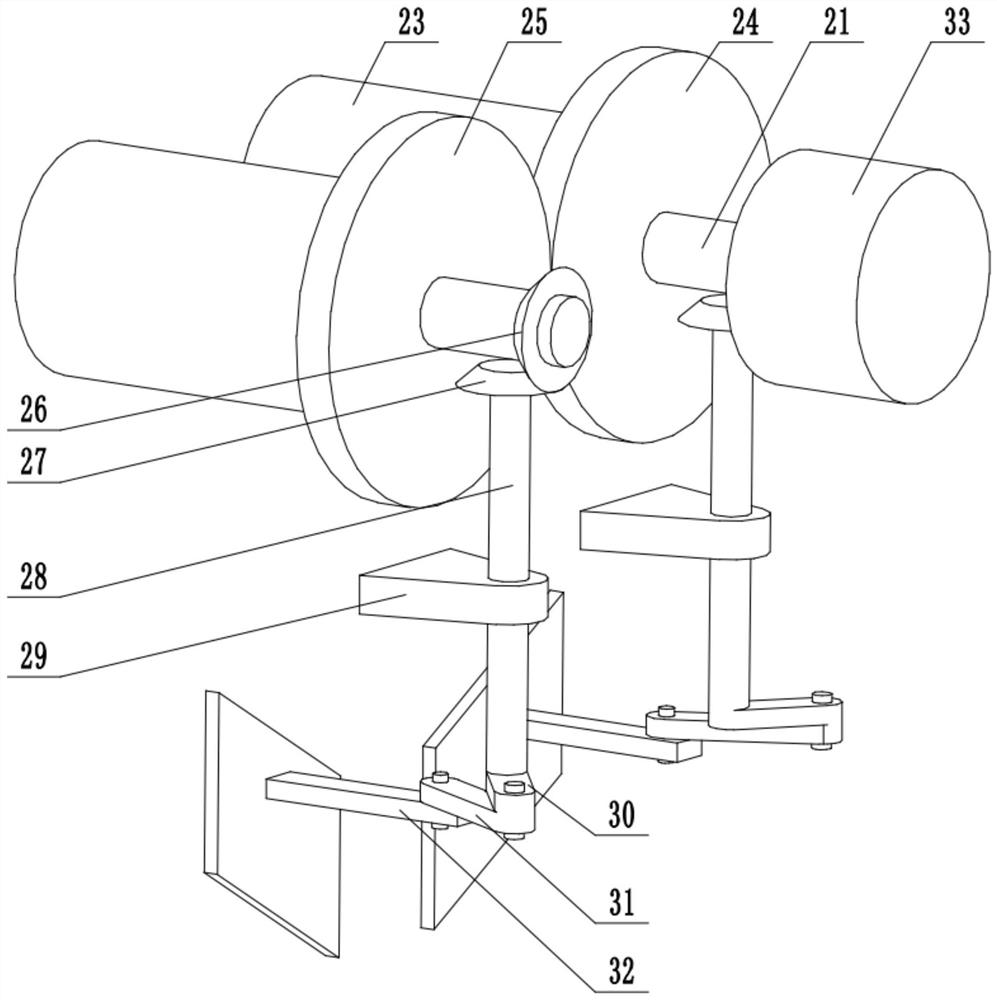

[0026] refer to Figure 1~3 , in an embodiment of the present invention, a chemical raw material crushing and grinding device includes a frame 2, a feed plate 1 is installed on the upper end of the frame 2, and a cutting device is installed on the upper part of the frame 2, and symmetrically arranged in the middle of the frame 2. The ventilation heating plate 3 is provided with a blowing device on the frame 2 located at the lower end of the ventilation heating plate 3, and the blowing device and the cutting device are connected by a transmission device, and a second motor 33 is installed on one side of the transmission device, and the bottom of the frame 2 Grinding cylinder 6 is installed on the inner side, and base plate 14 is installed on the lower end of frame 2, hollow grooves 13 are provided on both sides of base plate 14, and a grinding device is fixed in the middle part of the upper end of base plate 14, and a material receiving device is installed on the lower end of ba...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a blanking plate 5 is installed at the lower end of the ventilation heating plate 3, and a blanking plate 5 is installed on the frame 2 in the middle of the blanking plate 5. There is a feeding wheel 20, which is used to make the device to be ground fall at a constant speed, so as to ensure the uniformity of the ground particles.

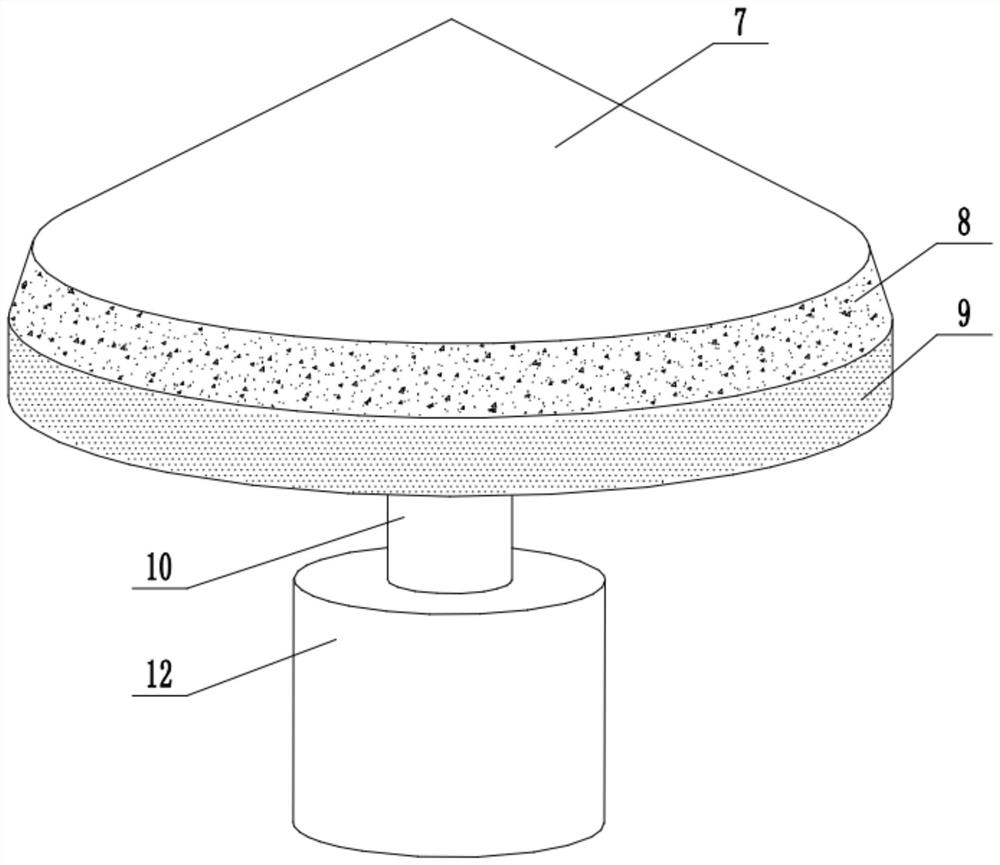

[0031]The working principle of the present invention is: the first motor 12 drives the output shaft 10 to rotate, the output shaft 10 drives the grinding and crushing block 9 to rotate, the grinding and crushing block 9 drives the upper grinding block 8 to rotate, and cooperates with the grinding cylinder 6 to grind the raw material into powder, while the second motor 33 drives the rotation shaft 21 on one side to rotate, and the rotation direction of the rotation shaft 21 on both sides is reversed by the meshing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com