Zoning, grading and synchronous tensioning construction method for double-layer spoke type closed cable net

A synchronous tensioning and spoke-type technology, applied in building components, special structures, buildings, etc., can solve the problems of low construction technical requirements, long site occupation period, and difficulty in product protection, so as to reduce the amount of aerial work and save money. Cost, effect of improving construction efficiency and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

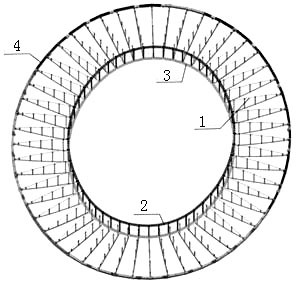

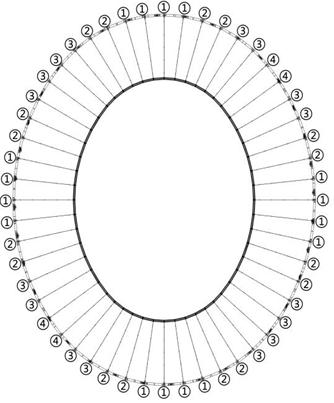

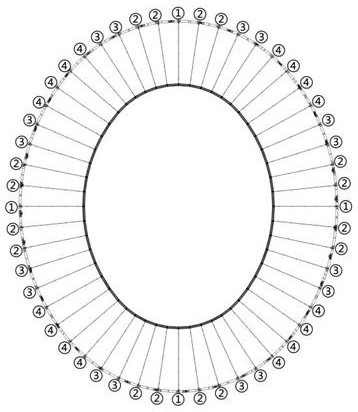

[0026] Such as Figure 1-Figure 3 Shown: Taking the double-layer spoke cable net structure of a stadium as an example, the structure is composed of 52 radial cable trusses 1, upper ring cables 2, and lower ring cables 3. According to the principle of symmetrical distribution, it is divided into 4 lifting and stretching batches. The specific implementation steps are as follows:

[0027] Step 1. Set up ring cables and radial cables to lay tire frame

[0028] Use the total station to locate the position of the cableway and lay the tire frame.

[0029] Step 2, hoop cable and upper and lower radial cable laying

[0030] When the cable body is laid, the hoisting machinery and the special cable reel are used to carry out the cable laying construction.

[0031] Step 3. Assemble the cable clip and lifting tool at low altitude

[0032] Install the ring cable clamp and the radial cable clamp according to the cable clamp marking line on the cable body, and use a torque wrench to perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com