Underground pipeline detection robot

A technology for detection of underground pipelines and pipelines, applied in the direction of supporting machines, pipe components, special pipes, etc., can solve problems such as robot detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

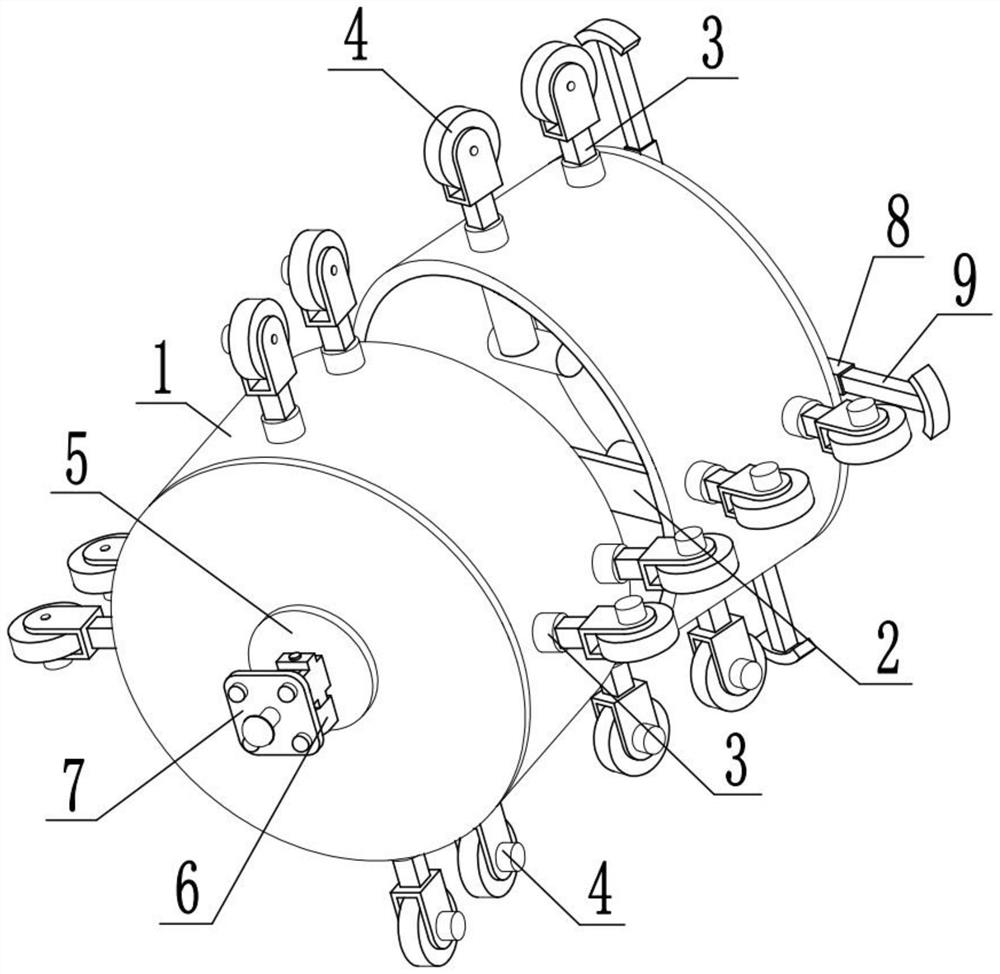

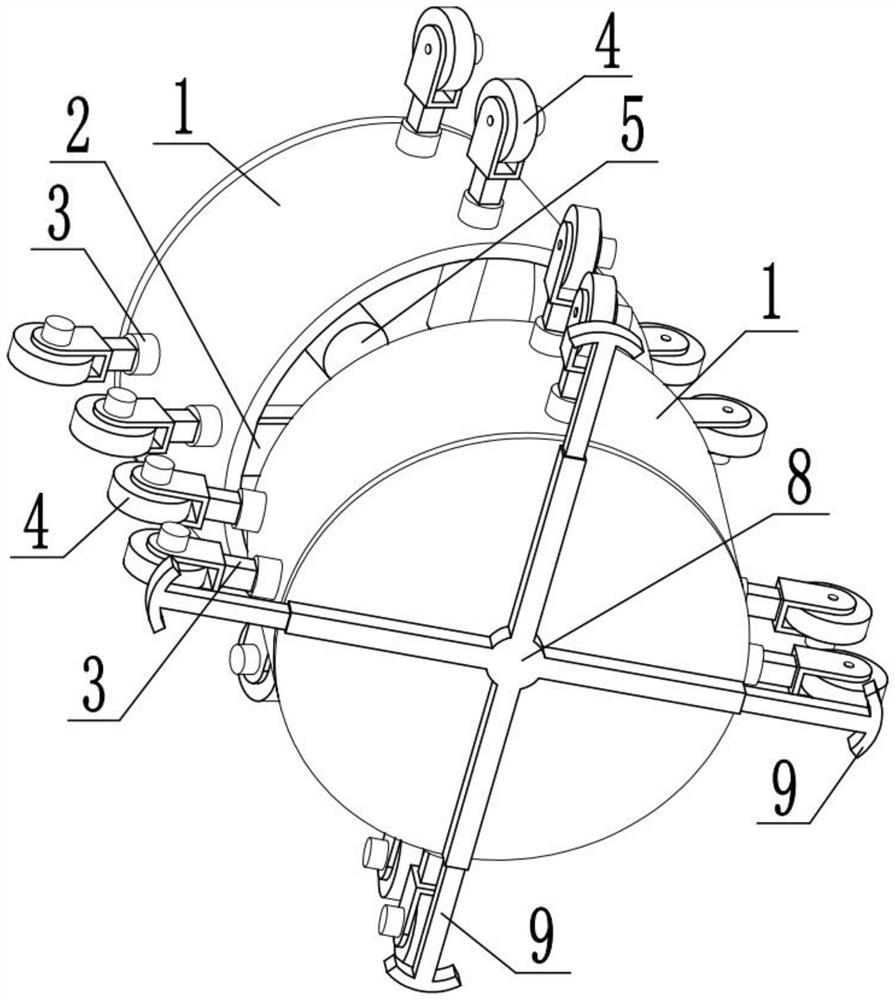

[0034] Combine below Figure 1-12This embodiment is described. The present invention relates to the technical field of underground pipelines, more specifically, an underground pipeline inspection robot, which includes a mobile bearing cavity member 1, a connecting hinge device 2, a telescopic bearing leg device 3, a moving roller member 4, and a detection bearing plate device. 5. Pipeline detection device 6, adjusting power device 7, dust removal power component 8 and telescopic dust removal device 9, place the device in the underground pipe, and a plurality of moving wheels 4-2 are in contact with the inner wall of the pipe, and start a plurality of motors I4- 3 Drive the moving wheel 4-2 to rotate, and drive the device to move in the pipeline. When the device encounters a bend, the two detection cavities 1-1 can be rotated by using the hinged seat 2-2 and the hinged plate 2-4 Finally, the two detection cavities 1-1 can pass through the bend, and the inner wall of the pipelin...

specific Embodiment approach 2

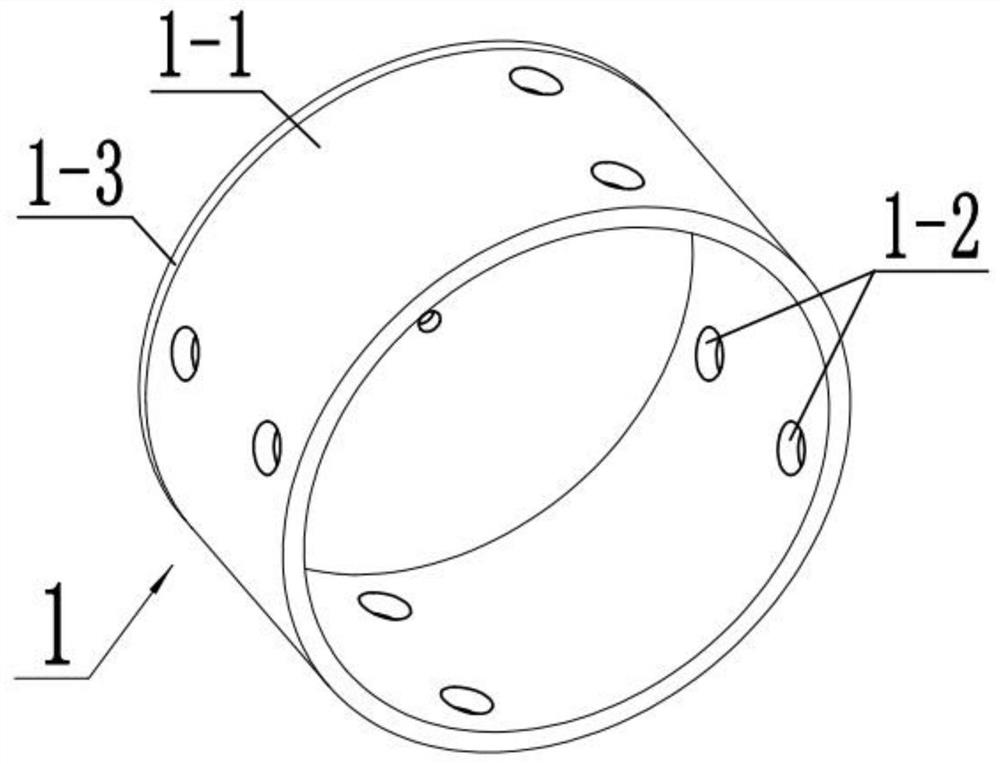

[0037] Combine below Figure 1-12 This embodiment will be described. This embodiment will further explain Embodiment 1. The mobile bearing chamber component 1 includes a detection cavity 1-1, a fixed socket 1-2, and an end side plate 1-3. The detection cavity 1-1 Playing the role of bearing connection, the detection cavity 1-1 is uniformly provided with a plurality of fixed jacks 1-2, and the plurality of fixed jacks 1-2 can provide a fixed space for a plurality of round and square sliding chambers 3-1, The outer end of the detection cavity 1-1 is fixedly connected with the end side plate 1-3, and the end side plate 1-3 acts as a space for carrying and fixing. 1 to realize the rotation of the device, ensure that the device can pass through the bend of the pipeline, and realize the detection of the curved pipeline. The two detection cavities 1-1 are fixedly connected with battery packs, and the two battery packs can be It can be disassembled and can be recharged and recycled. ...

specific Embodiment approach 3

[0039] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the connection hinge device 2 includes a fixed plate I2-1, a hinge seat 2-2, a fixed plate II2-3 and a hinged plate 2-4, A hinged seat 2-2 is fixedly connected to the fixed plate I2-1, and a hinged plate 2-4 is fixedly connected to the fixed plate II2-3. The hinged seat 2-2 and the hinged plate 2-4 are connected through a hinge, and the fixed plate I2-1 and the fixed plate II2-3 are fixedly connected to the inner ends of the two detection cavities 1-1 respectively. When the device encounters a curved pipe, the two detection cavities 1-1 need to have a certain angle. The hinged connection between the hinged seat 2-2 and the hinged plate 2-4 realizes the rotation between the two detection cavities 1-1, and finally there will be an angle between the two detection cavities 1-1, so that the device can pass through the Bent pipes to realize the detection of curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com