Sand acid low-position waste heat recovery method and recovery system thereof

A waste heat recovery, low-level technology, applied in the field of sand acid low-level waste heat recovery method and its recovery system, can solve problems such as insufficient heat utilization, achieve the effects of less heat waste, increase dilution heat, and increase steam production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

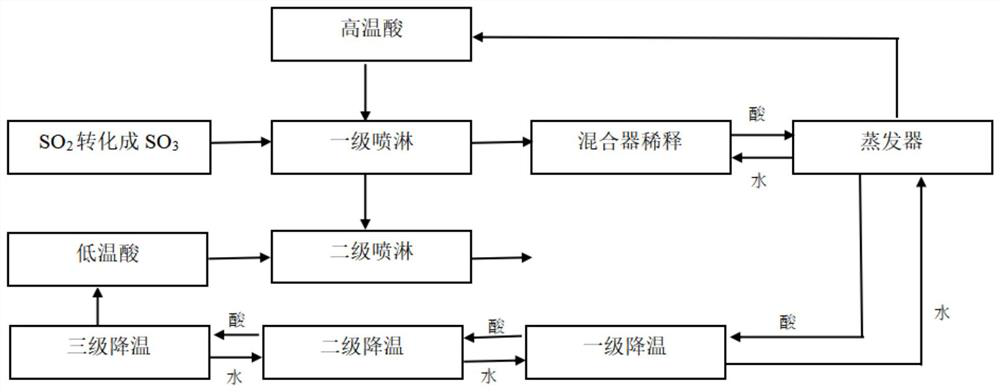

[0034] This embodiment processes SO according to the following steps 2 converted to SO 3 After the gas:

[0035] (1) SO 2 converted to SO 3 Afterwards, two-stage spraying was used to absorb SO 3 , the primary spray uses high-temperature acid with a mass fraction of 99.3% and 200°C, and the secondary spray uses low-temperature acid with a mass fraction of 98.5% and 70°C;

[0036] (2) The high-temperature acid with a mass percentage of not less than 99.5% output by the primary spray tower is passed into the mixer and diluted with water to obtain high-temperature acid at about 260°C;

[0037] (3) The high-temperature acid diluted with water is sent to the evaporator, where it exchanges heat with the water in the evaporator to generate steam. The temperature of the high-temperature acid after heat exchange is 200°C. According to the concentration and the liquid level of each circulation tank, part of it is sent back to the first stage Spraying, part of which is cooled down st...

Embodiment 2

[0044] This embodiment processes SO according to the following steps 2 converted to SO 3 After the gas:

[0045] (1) SO 2 converted to SO 3 Afterwards, two-stage spraying was used to absorb SO 3 , the primary spray uses high-temperature acid with a mass fraction of 99.3% and 200°C, and the secondary spray uses low-temperature acid with a mass fraction of 98.5% and 70°C;

[0046] (2) The high-temperature acid with a mass percentage of not less than 99.5% output by the primary spray tower is passed into the mixer and diluted with water to obtain high-temperature acid at about 260°C;

[0047] (3) The high-temperature acid diluted with water is sent to the evaporator, where it exchanges heat with the water in the evaporator to generate steam. The temperature of the high-temperature acid after heat exchange is 200°C. According to the concentration and the liquid level of each circulation tank, part of it is sent back to the first stage Spraying, a part of the temperature is grad...

Embodiment 3

[0050] This embodiment processes SO according to the following steps 2 converted to SO 3 After the gas:

[0051] (1) SO 2 converted to SO 3 Afterwards, two-stage spraying was used to absorb SO 3 , the primary spray uses high-temperature acid with a mass fraction of 99.1% and 200°C, and the secondary spray uses low-temperature acid with a mass fraction of 98.5% and 70°C;

[0052] (2) High-temperature acid with a mass percentage of not less than 99.5% output from the primary spray tower is passed into the mixer and diluted with water to obtain high-temperature acid at about 250°C;

[0053] (3) The high-temperature acid diluted with water is sent to the evaporator, where it exchanges heat with the water in the evaporator to generate steam. The temperature of the high-temperature acid after heat exchange is 200°C. According to the concentration and the liquid level of each circulation tank, part of it is sent back to the first stage Spraying, part of which is cooled down step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com