A high-temperature negative pressure ventilation disinfection machine and its disinfection method

A technology of disinfection machine and negative pressure fan, which is applied in the direction of disinfection, heating methods, mechanical equipment, etc., can solve the problems of infection and virus inclusion of people in close contact, and achieve the goal of improving equipment safety, killing viruses quickly, and increasing lifespan Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

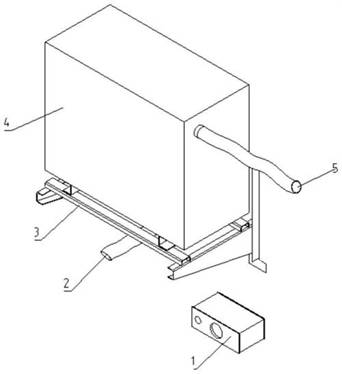

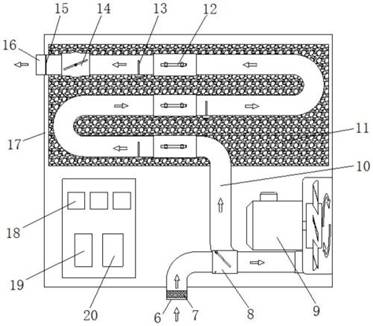

[0034] Specific implementation mode one: see Figure 1-8 This embodiment will be described. The high-temperature negative pressure ventilation disinfection machine described in this embodiment includes a differential pressure control valve 1, an air inlet 6, an inlet filter 7, a check valve 8, a negative pressure fan 9, a pipeline A10, a pipeline B, a heat preservation Material 11, several heating rods 12, several temperature sensors 13, butterfly valve 14, outlet filter screen 15, air outlet 16 and waterproof casing 17, the pressure difference control valve 1 is installed on the wall to control outdoor air entering the room,

[0035] The bottom of the waterproof casing 17 is provided with an air inlet 6, and an inlet filter 7 is installed at the air inlet 6, and the gas entering the air inlet 6 is divided into two paths at the check valve 8, and one path passes through the pipeline B and the negative The compressor 9 is connected, and the other is connected to the air outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com