Battery box

A battery box and protective box technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of affecting battery installation efficiency, shortening battery service life, poor battery protection performance, etc., and achieve the effect of improving heat dissipation and ventilation , Improve the efficiency of heat dissipation and improve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

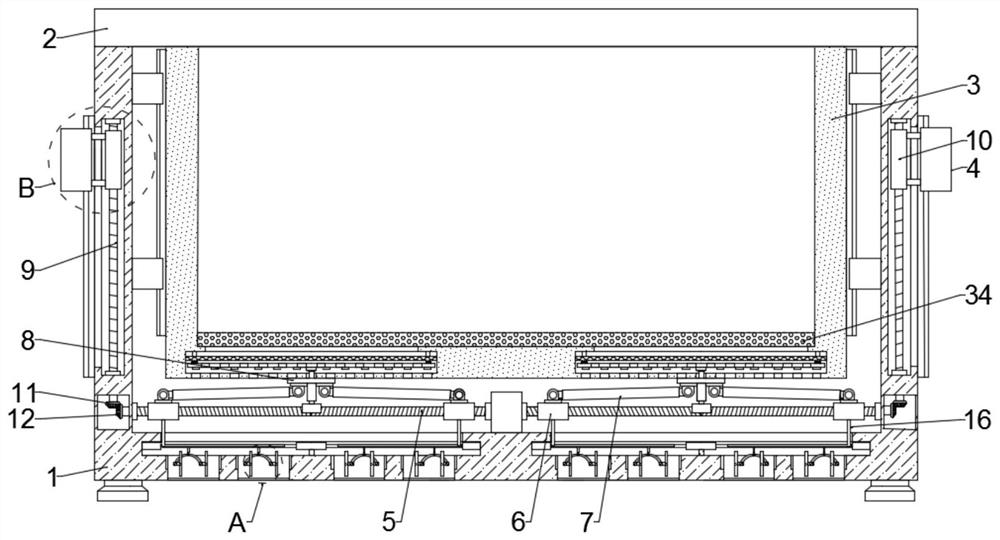

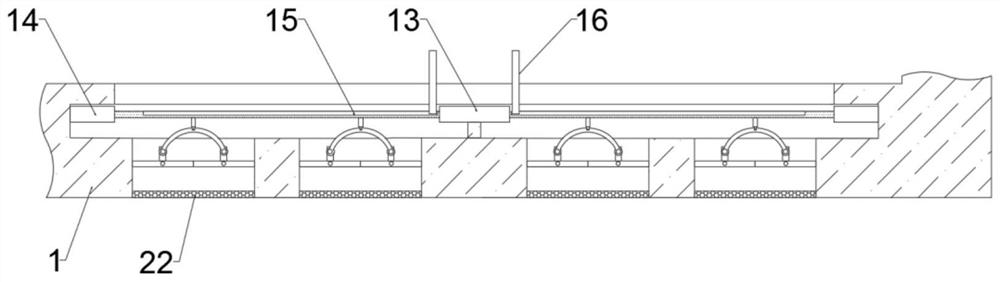

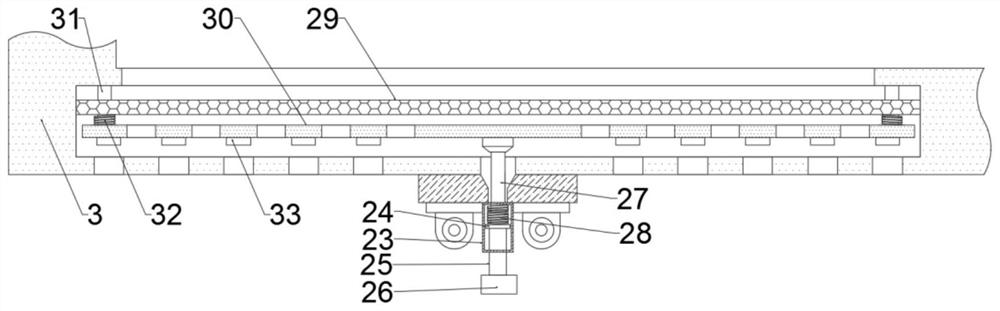

[0028] Embodiment 1: see Figure 1-7, a battery box, including a protective box 1, a jacking mechanism, an adjustment assembly, a ventilation mechanism, a transmission assembly, a heat dissipation mechanism and a reset assembly, the protective box 1 is a horizontally arranged rectangular box, and the top opening of the protective box 1 passes through the rear end The hinge is hinged with a box cover 2, and the protective box 1 is horizontally provided with an installation box 3 with the opening facing upwards. The bottom of the installation box 3 is horizontally provided with a shock-absorbing and heat-dissipating pad 34, and the inner bottom of the protective box 1 is provided with a jacking mechanism. Both sides of the protective box 1 are provided with adjustment chambers vertically in the middle of the box body, and adjustment components are arranged in the adjustment chambers; both sides of the middle part of the bottom surface of the protective box 1 are horizontally prov...

Embodiment 2

[0033] Embodiment 2: In this embodiment, the present invention also proposes a method for using the battery case, including the following steps:

[0034] Step 1, when it is necessary to install the battery, first open the box cover 2, and drive the jacking mechanism to rotate through the adjustment component, and the jacking mechanism is used to facilitate the lifting of the installation box 3; so that the operator can install the battery in the installation box 3;

[0035] Step 2: The operator simultaneously pushes down the slide plate 4 to descend on the T-shaped guide rail. The slide plate 4 descends to drive the threaded cylinder 10 at the inner end of the connecting rod to descend, and the threaded cylinder 10 is connected to the screw rod 9 , it is convenient to make the screw rod 9 rotate during the descending process of the threaded cylinder 10, the rotation of the screw rod 9 is convenient to drive the active bevel gear 11 to rotate, and the meshing transmission betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com