Electric motors, powertrains and equipment

A technology of oil passages and nozzles, applied in the field of motors, can solve the problems of poor heat dissipation of the stator core and coil windings, and excessive temperature of the coil windings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

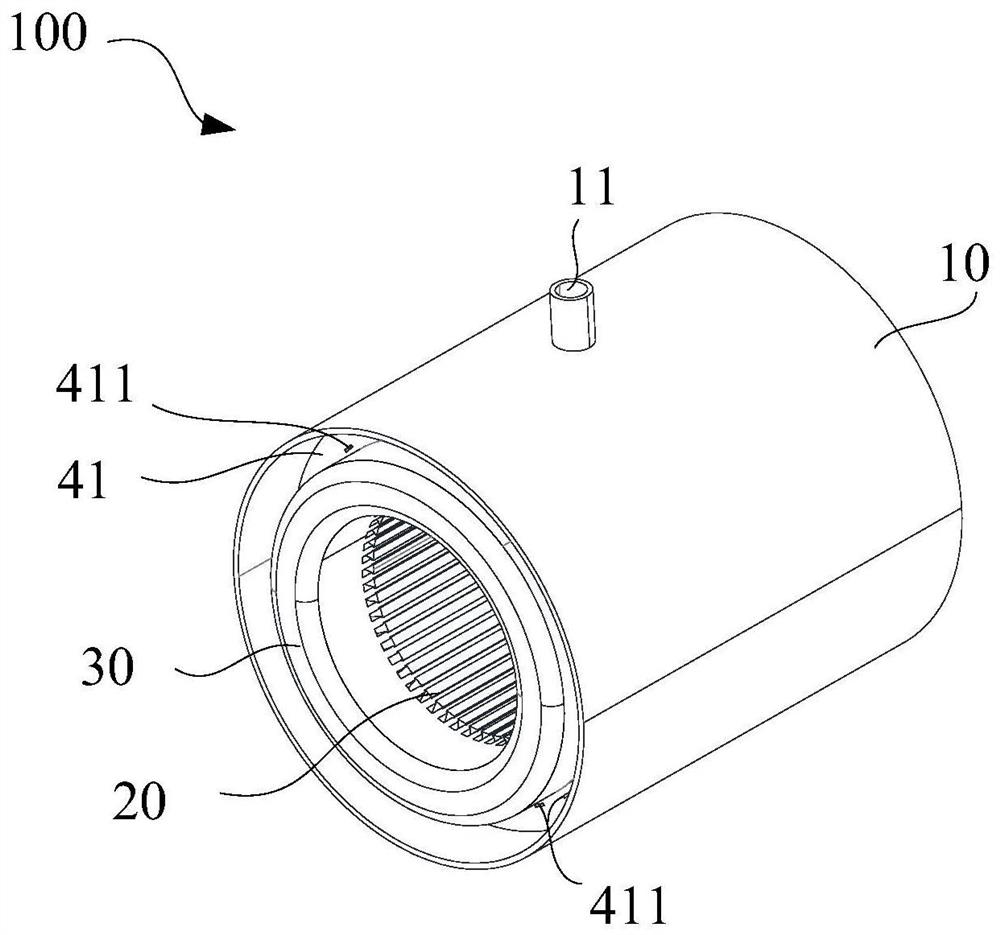

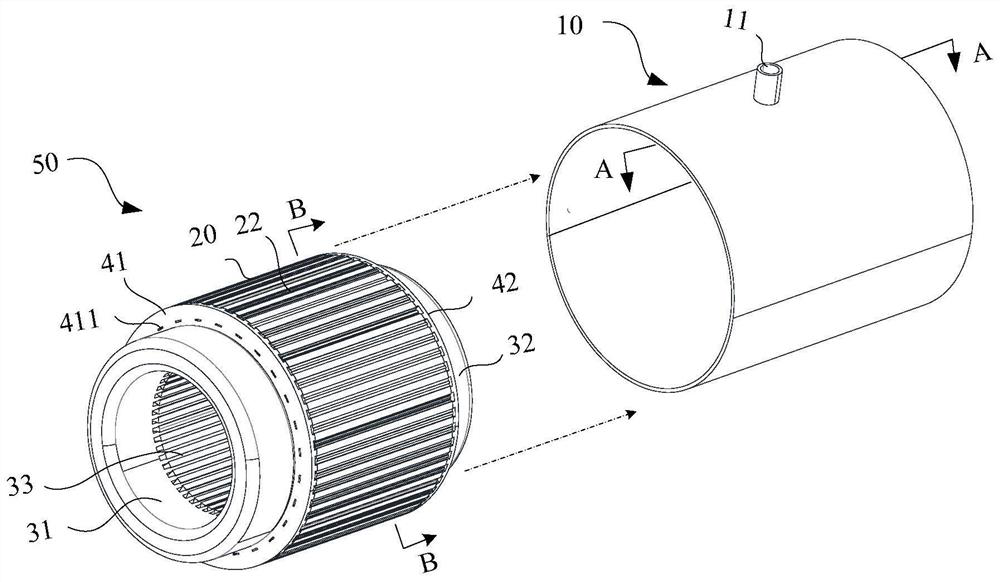

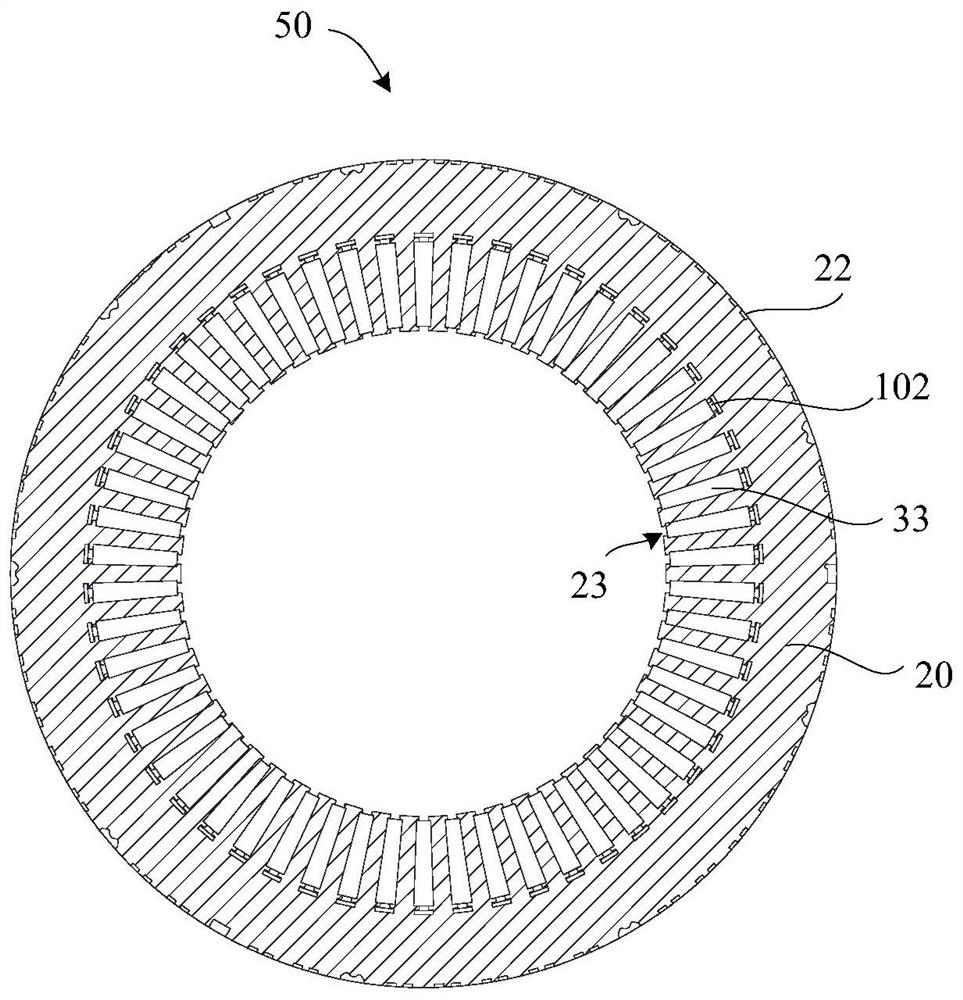

[0184] In the embodiment of this application, see Figure 17 As shown, the first end cover 41 at least includes: a first annular end plate 401, and a third oil passage 103 is formed between the first annular end plate 401 and one end surface of the stator core 20 (see the following Figure 25 ). see Figure 21 The second end cover 42 shown at least includes: a second annular end plate 402, and a fourth oil passage 104 is formed between the second annular end plate 402 and the other end surface of the stator core 20 (see the following Figure 25 ).

[0185] see Figure 17 As shown, a plurality of first nozzles 411 are arranged at intervals along the circumferential direction of the first annular end plate 401, see Figure 20 As shown, a plurality of second nozzles 421 are arranged at intervals along the circumferential direction of the second annular end plate 402 . In this way, the cooling oil ejected from a plurality of first nozzles 411 can evenly dissipate heat in the ...

Embodiment 2

[0196] The difference between the embodiment of the present application and the first embodiment above is: in the embodiment of the present application, see Figure 27 with Figure 28A As shown, the first nozzle 411 is a circular nozzle, see Figure 28B As shown, the second nozzle 421 is a circular nozzle, see Figure 29 As shown, a plurality of first nozzles 411 are evenly spaced in the circumferential direction. see Figure 30 As shown, the first nozzle 411 is opened on the first recess 417 of the first blocking block 416 , and the first nozzle 411 is close to the outer ring of the first end cap 41 .

[0197] In the embodiment of the present application, when the first nozzle 411 and the second nozzle 421 are set as circular nozzles, under the same oil pressure, the circular nozzles can make the cooling oil spray to the two sides of the coil winding 30 at a faster speed. on one end.

[0198] In the embodiment of the present application, the nozzle is an inclined nozzle ...

Embodiment 3

[0202] The difference between the embodiment of the present application and the above two embodiments is: in the embodiment of the present application, the first nozzle 411 and the second nozzle 421 can be arranged face to face with the first end 31 and the second end 32, Figure 35 for Figure 34 The perspective view of the stator after the middle housing 10 is removed, see Figure 35 As shown, the first end cover 41 also includes: a first extension plate 403 protruding axially and connected to the outer edge of the first annular end plate 401 , that is, one end of the first extension plate 403 is connected to the first annular end plate 401 The outer edges of the first extension plate 403 protrude outward along the axial direction of the stator core 20 . The second end cover 42 also includes: a second extension plate 404 protruding axially and connected to the outer edge of the second annular end plate 402 , that is, one end of the second extension plate 404 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com