Anti-freezing spiral juice squeezer used for juice production

A screw juicer, juice technology, applied in application, juice extraction, cleaning methods and utensils, etc., can solve the problems of sticking to the discharge port, damage, congestion, etc., to reduce vulnerability, facilitate maintenance, avoid The effect of sticky congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

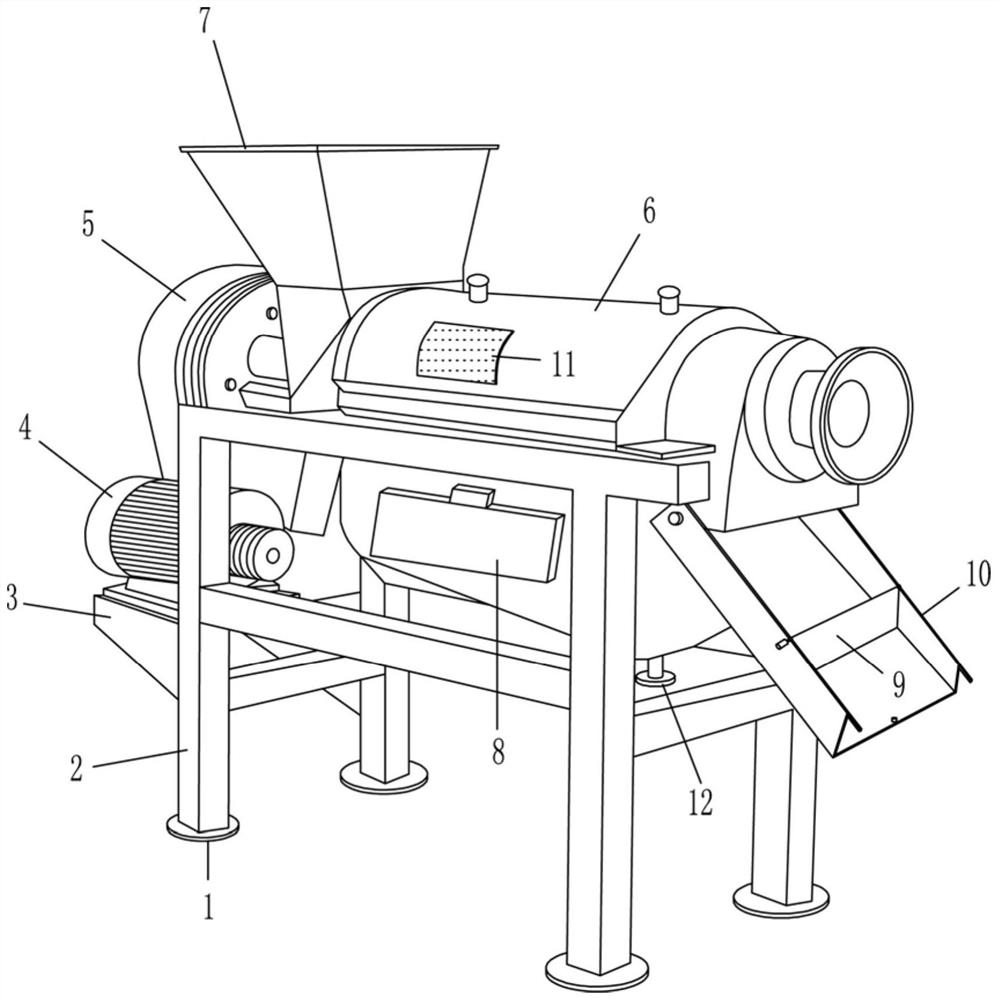

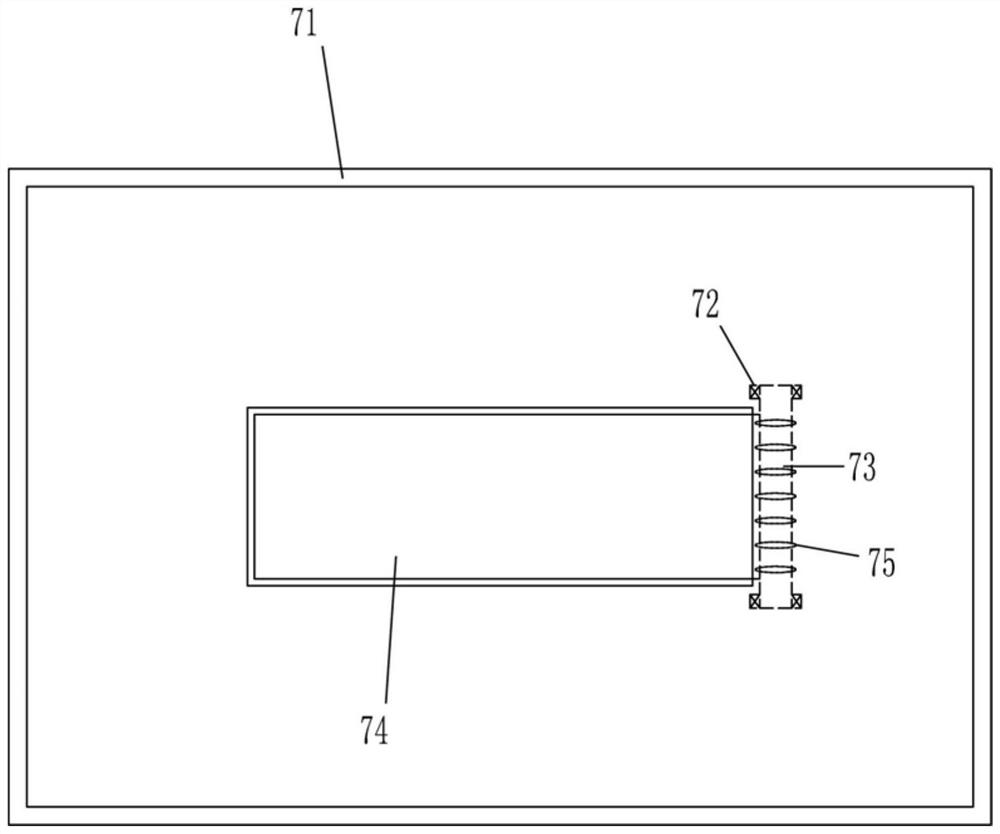

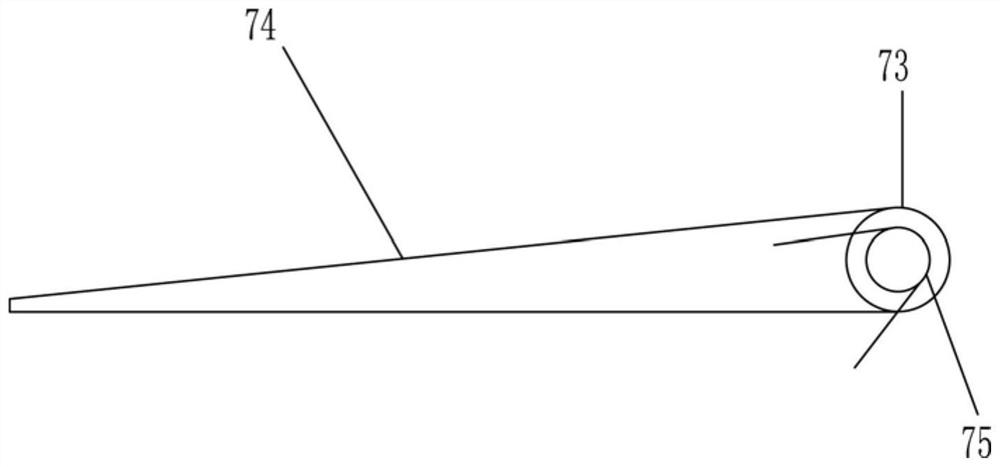

[0026] An antifreeze type screw juicer for fruit juice production, such as Figure 1-8 As shown, it includes a foot pad 1, a support frame 2, a load-bearing frame 3, a drive motor 4, a linkage unit 5, a crushing device 6, a feeding component 7, an antifreeze component 9, a scraping component 8, a discharge trough 10, and an observation The glass 11 and the juice outlet pipe 12; the support frame 2 is fixed on the top of the foot pad 1; the load-bearing frame 3 is fixed on the support frame 2; the driving motor 4 is fixed on the load-bearing frame 3; the crushing device 6 is fixed on the support frame 2, and broken A screw shaft group 61 is installed in the equipment 6; the linkage unit 5 can crush the side wall of the equipment 6, and is connected to the output end of the driving motor 4; the screw shaft group 61 is connected to the output end of the linkage unit 5; the feed assembly 7 is fixed On the top of the crushing equipment 6, and communicated with the inside of the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com