Full-automatic assembling equipment for electric saw chains

An assembly equipment, fully automatic technology, applied in the direction of metal chains, etc., to achieve the effect of low cost, strengthen the fixing function, and prevent shaking and shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

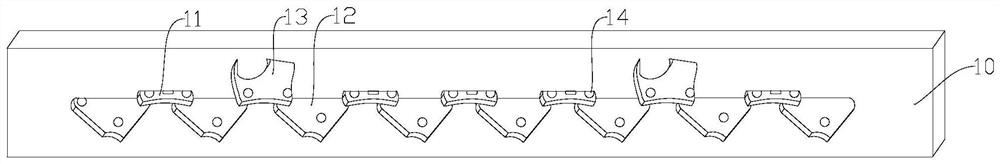

[0030] Such as Figure 1~6 As shown, it is a three-dimensional structural schematic diagram of a fixed plate in a fully automatic chainsaw chain assembly equipment. The automatic chainsaw chain assembly equipment of this embodiment includes a bottom chain plate 10, an upper chain plate 20, and a chain 40. One side of the lower chain plate 10 is provided with a connecting piece groove 11, a driving piece groove 12, and a blade groove 13. The inside of the lower loading chain plate 10 is provided with a first connecting hole 14, and the first connecting hole 14 runs through the Install the chain plate 10 below, the first connection hole 14 passes through the transmission piece groove 12, the blade groove 13, the described connection piece groove 11 is connected with two groups of transmission piece grooves 12 through the first connection hole 14, the described The drive slot 12 passes through the first connecting hole 14 and connects the blade slot 13. The drive slot 12 is distr...

Embodiment 2

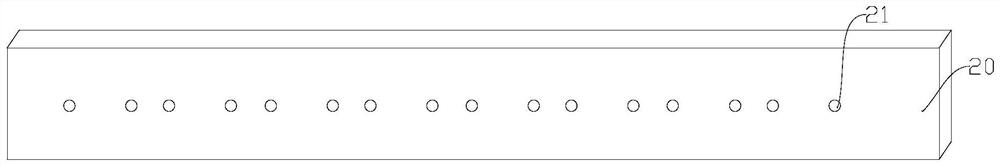

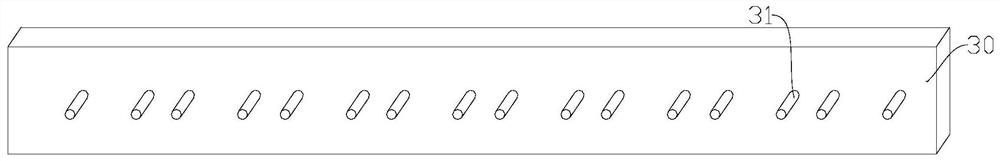

[0036] Such as image 3 As shown, it is a three-dimensional structural schematic diagram of a fully automatic assembly equipment for chainsaw chains in another preferred embodiment of the present invention. On the basis of Example 1, the construction safety protection improvement device of this example includes a fixing plate 30, so The fixed plate 30 is connected with the lower chain plate 10 through the clamping rod 31 and the first connecting hole 14, and the fixed plate 30 is connected with the upper chain plate 20 through the clamping rod 31 and the second connecting hole 21. There are sixteen groups of rods 31, and the clamping rods 31 are linearly arranged on one side of the fixing plate 30, and the positions of the clamping rods 31 correspond to the positions of the first connecting holes 14 one by one;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com