A Parallel Mechanism Containing Multiple Slide Rails and Composite Branch Chains

A multi-slide, parallel technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of inability to guarantee high-precision work execution, reduce the working space of the mechanism, and low flexibility, and achieve convenient processing, manufacturing and replacement. The effect of saving resources and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The parallel mechanism provided by the present invention containing multiple sliding rails and composite branch chains will be described in detail below in conjunction with the accompanying drawings.

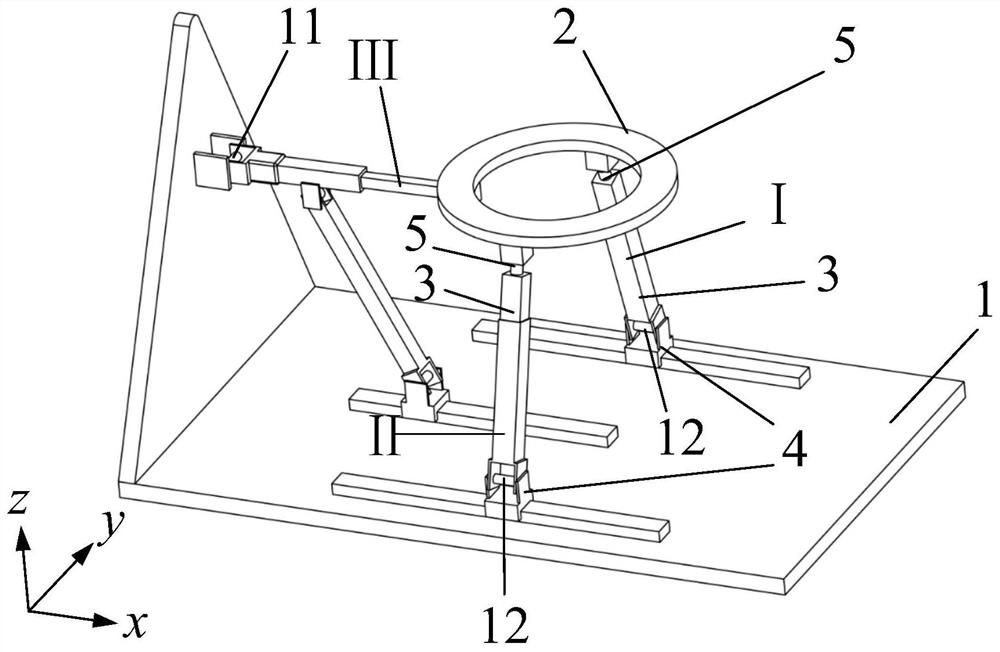

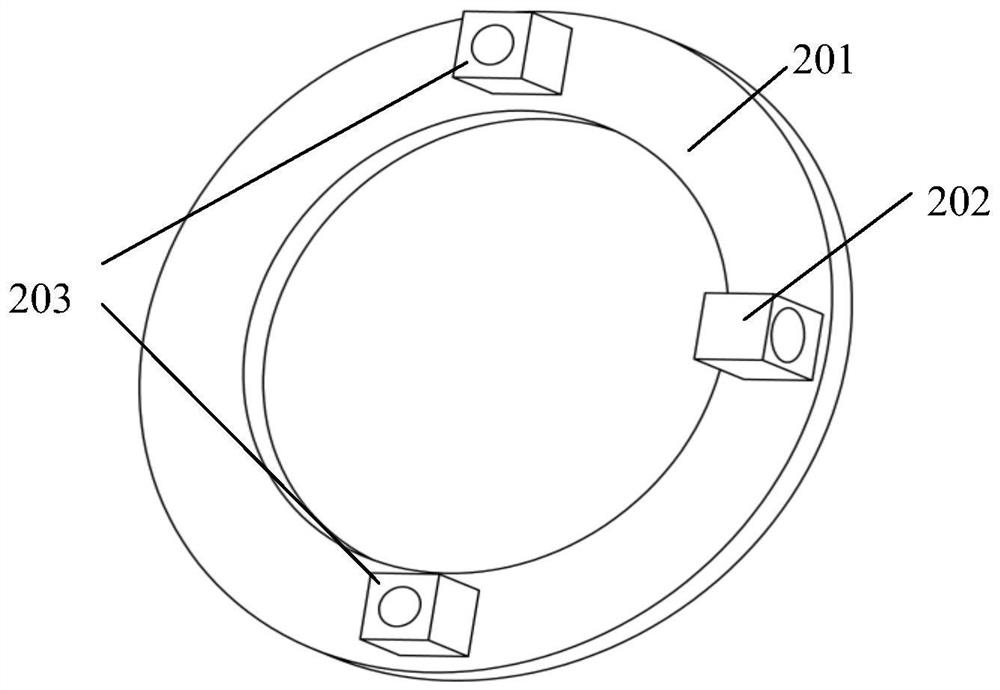

[0024] Such as Figure 1-Figure 5 As shown, the parallel mechanism with multiple sliding rails and compound branches provided by the present invention includes a base 1, a moving platform 2, a first compound drive branch I, a second compound drive branch II and a third compound branch III;

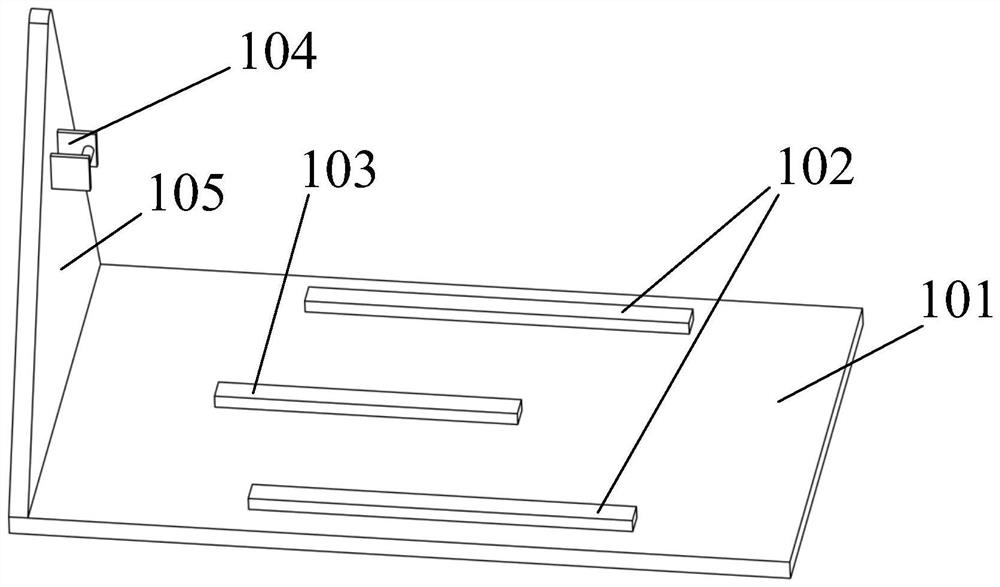

[0025] The base 1 includes a base plate 101, two first slide rails 102, a second slide rail 103, a first hinged support 104 and a frame 105; wherein the two first slide rails 102 are fixed on the Both sides of the upper surface of the base plate 101; the second slide rail 103 is fixed on the middle part of the upper surface of the base plate 101, and is parallel to the first slide rail 102; the frame 105 is vertically fixed on one end of the upper surface of the base plate 101 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com