multifunctional scissors

A scissor machine and multi-functional technology, applied in the field of spring processing, can solve the problems of cutting control, small stitching gap, huge cost, etc., and achieve the effect of ensuring the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

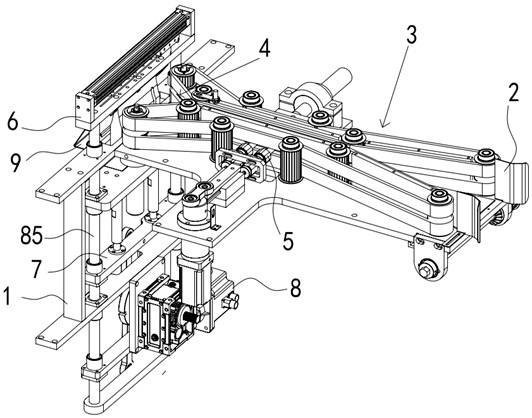

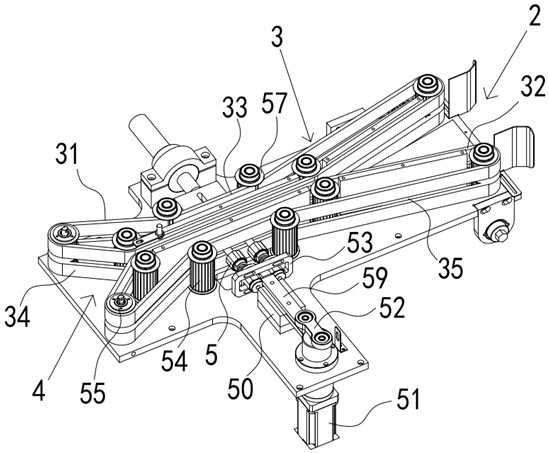

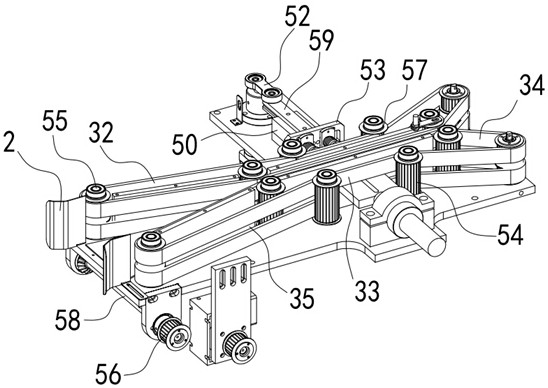

[0034] Such as Figures 1 to 5 As shown, the multifunctional scissors machine includes a short spring welding device and a scissors device.

[0035] Such as figure 2 , 3 As shown, the short spring welding device includes a spring feed inlet 2, a feed guide rail 3 and a spring discharge outlet 4 arranged in sequence. The feed guide rail 3 includes two symmetrically arranged feed conveyor belts 31, and a feed conveyor belt 31 is formed between the two feed conveyor belts 31. Space, feeding conveyor belt 31 comprises conveyor belt infeed part 32, conveyer belt processing part 33 and conveyer belt discharge part 34, two conveyer belt infeed parts 32 are arranged in the shape of bell mouth, and conveyer belt infeed part 32 bell mouth small mouth ends and conveyer belt processing part 33 Connection, the conveyor belt feeding part 32 is matched with the spring feeding port 2, the two conveyor belt processing parts 33 are arranged in parallel, the two conveyor belt discharge parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com