Material arranging device used for sheath visual inspection machine

A detection machine and material sorting technology, which is applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve problems such as the inability to arrange sheaths, achieve the effects of avoiding losses, reducing production costs, and ensuring the accuracy of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

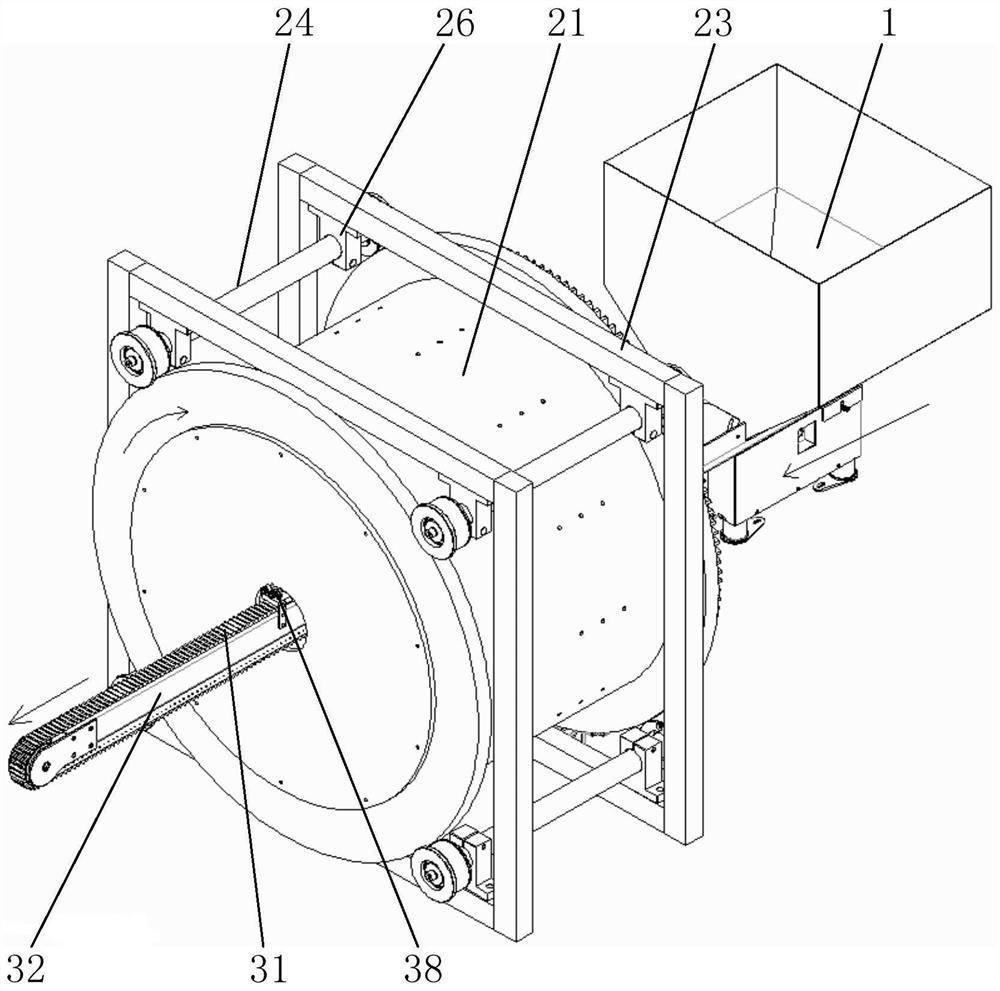

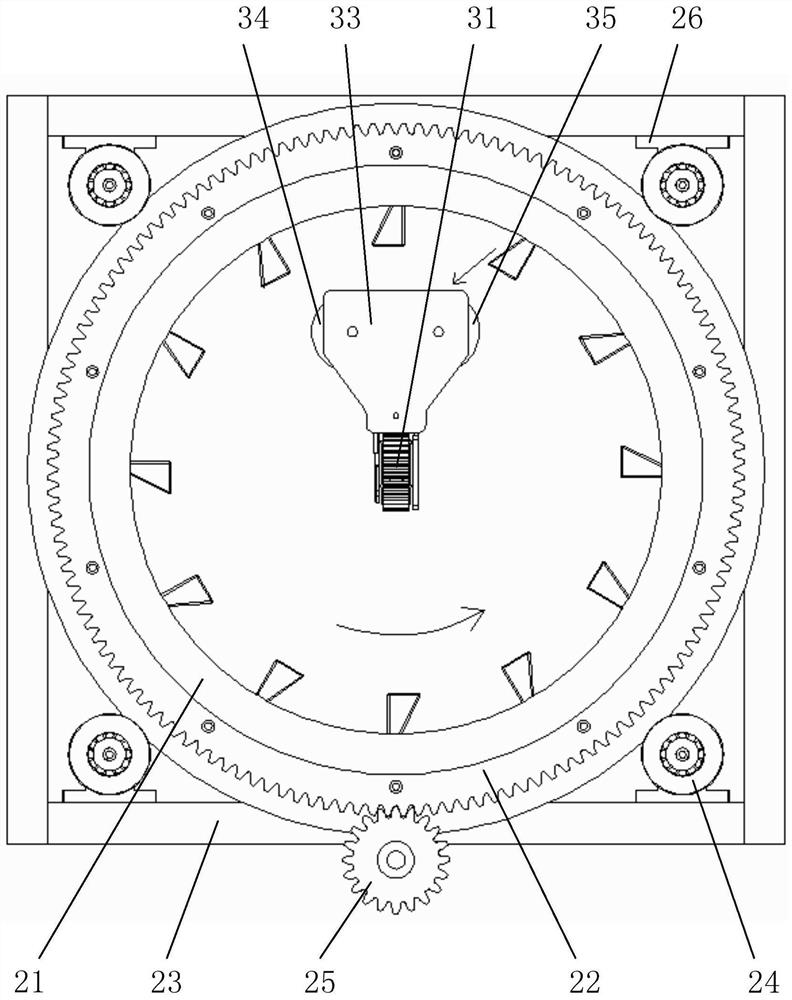

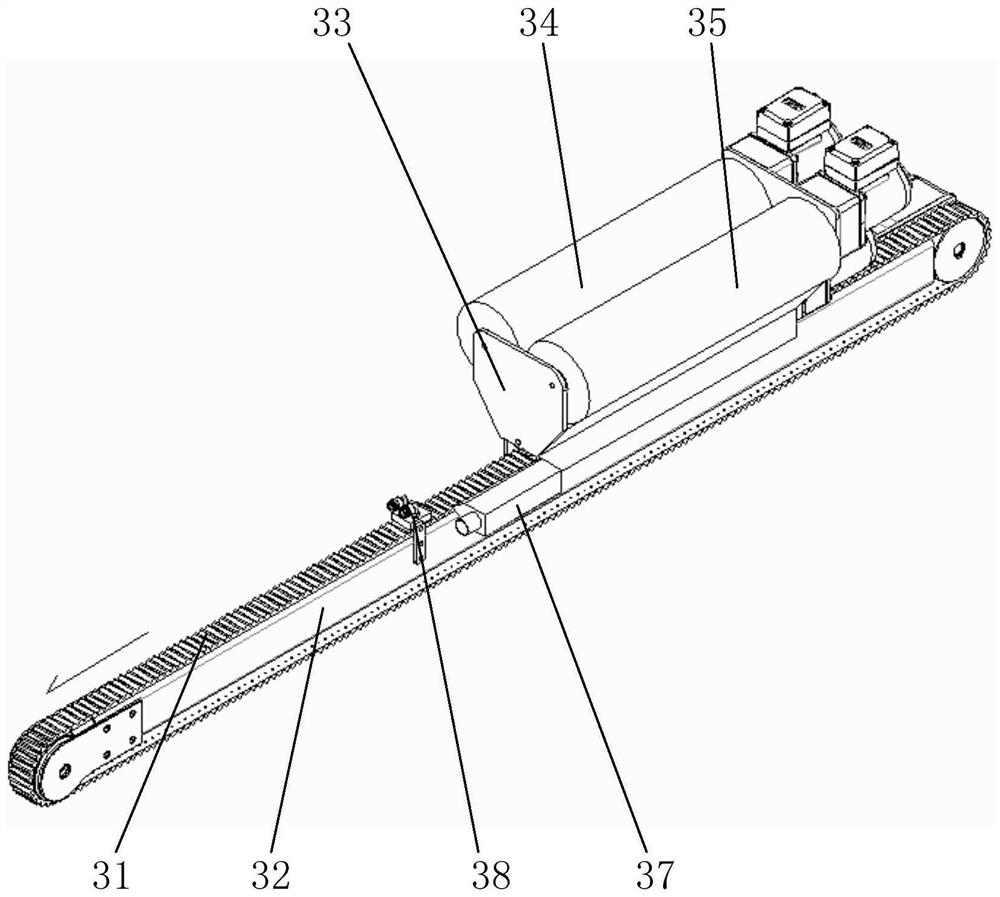

[0033] Through the following examples, combined with the attached Figure 1-5 , the technical solution of the present invention will be further specifically described.

[0034] as attached figure 1 Shown, the present invention is a kind of material management device for sheath visual inspection machine, and this material management device comprises feed module 1, drum material management module and material management conveying module; Wherein, feed module 1 and drum material management Module connection, the sheath is input into the drum sorting module, and the drum sorting module is connected with the sorting and conveying module, and the sheaths are sorted and then input into the sorting and conveying module for subsequent detection.

[0035] The feeding module 1 includes a feeding bin, a flow limiting plate, a feeding channel and a linear vibrator; the feeding bin is in an inverted trapezoidal shape, and the top is provided with a feeding port for inputting the sheath to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com