Full-paving periodic cushion layer vibration reduction ballast bed

A technology of cushion and full laying, which is applied to the field of full laying period cushion vibration damping track bed, can solve the problems of increasing the maintenance and repair workload of the wheel-rail system, affecting the driving stability and safety, and increasing the vibration participation quality, etc. The effect of rail system burden, saving vibration reduction cost investment, and good low frequency vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment

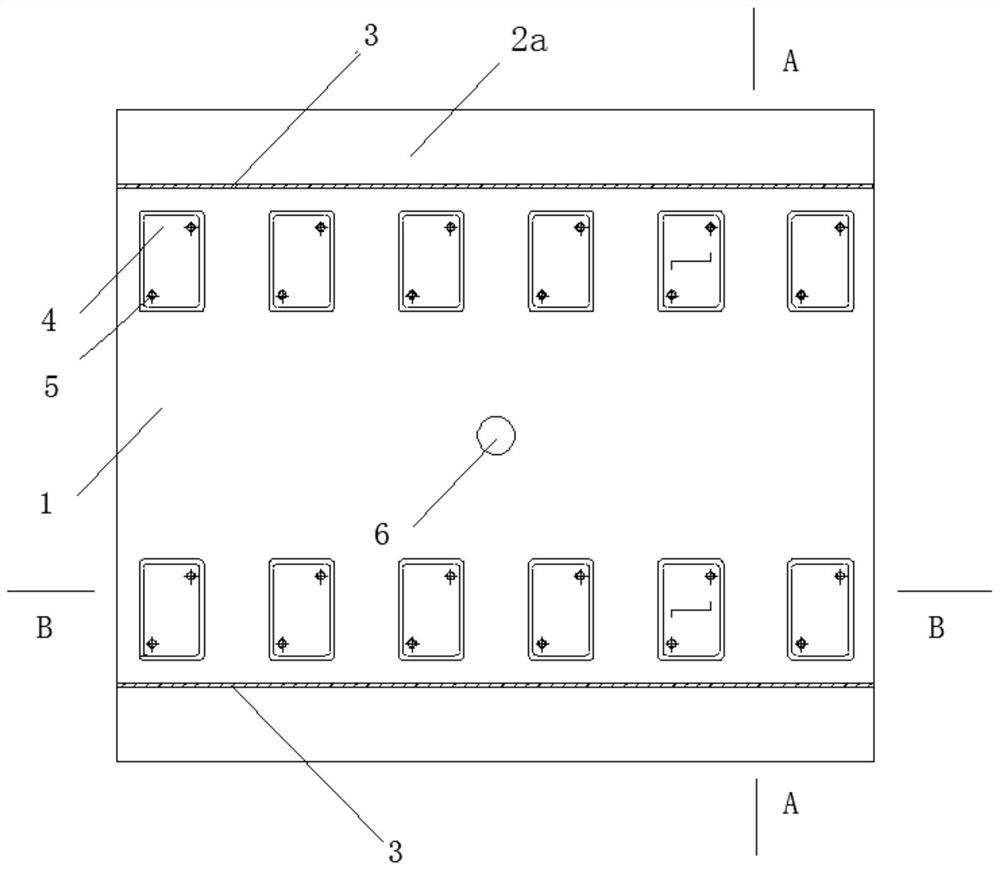

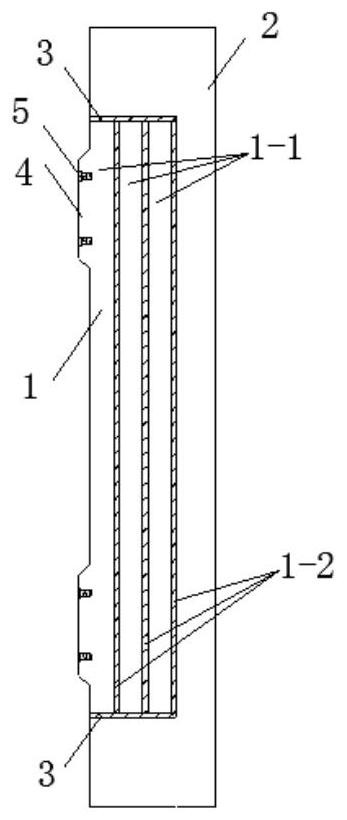

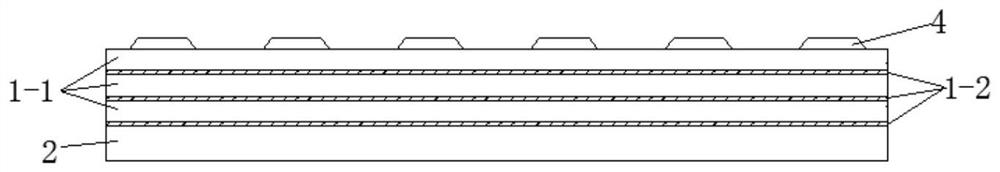

[0049] The width of the concrete slab 1-1 and the periodic cushion 1-2 is 2.2m, the thickness of the concrete slab 1-1 is 0.1m, the periodic cushion 1-2 is made of rubber material with a thickness of 0.01m, and the concrete The slab (1-1) and the periodic bedding layer 1-2 are alternately repeated from top to bottom, each repeated three times to form a periodic composite track bed slab 1 with a thickness of 0.33m. The thickness of the base of the concrete base and the limit structure 2 is 0.15m, and the height of the protrusion is 0.33m.

[0050] Figure 1-3 In the illustrated embodiment, the cross-sectional dimension of the discrete protrusions is 0.4m×0.5m (0.5m is the dimension along the running direction of the line). Figure 4-6 In the shown implementation, the longitudinal cross-sectional dimension of the continuous protrusion is 0.33m×0.4m (0.4m is the dimension perpendicular to the running direction of the line).

[0051] The elastic pad 3 is rubber with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com