An Industrial Pulverized Coal Boiler with Dual Horizontal Furnaces Contrasted Arrangement

A pulverized coal boiler, double-level technology, applied in the direction of using multiple fuel combustion, burning powder fuel burners, burning block fuel and powder fuel, etc., can solve the problem of outage maintenance, long-term continuous operation, etc. problem, to achieve the effect of guaranteed load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

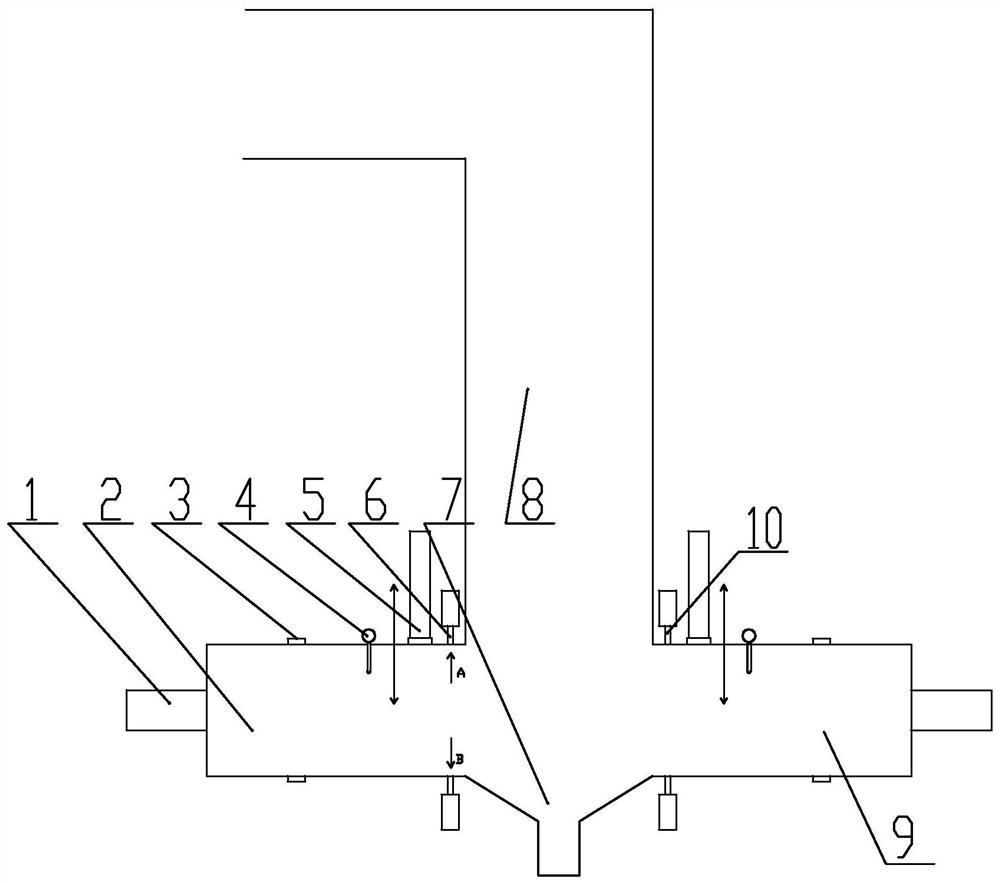

[0032] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, an industrial pulverized coal boiler with dual horizontal furnaces facing each other in this embodiment includes a burner 1, a No. 1 horizontal furnace 2, a flue gas baffle 5, a No. 1 flue gas recirculation tube bundle 6, a rising Furnace 8, No. 2 horizontal furnace 9, No. 2 flue gas recirculation tube bundle 10 and steam-water circulation unit;

[0033] One side of the rising furnace 8 is provided with a No. 1 horizontal furnace 2, and the other side of the rising furnace 8 is provided with a No. 2 horizontal furnace 9. Both the No. 1 horizontal furnace 2 and the No. 2 horizontal furnace 9 are connected to the rising furnace 8. Furnace 2 and No. 2 horizontal furnace 9 are arranged opposite to the ascending furnace 8, and the joints of No. 1 horizontal furnace 2 and No. 2 horizontal furnace 9 and ascending furnace 8 are provided with flue gas baffles 5, and the flue gas baff...

specific Embodiment approach 2

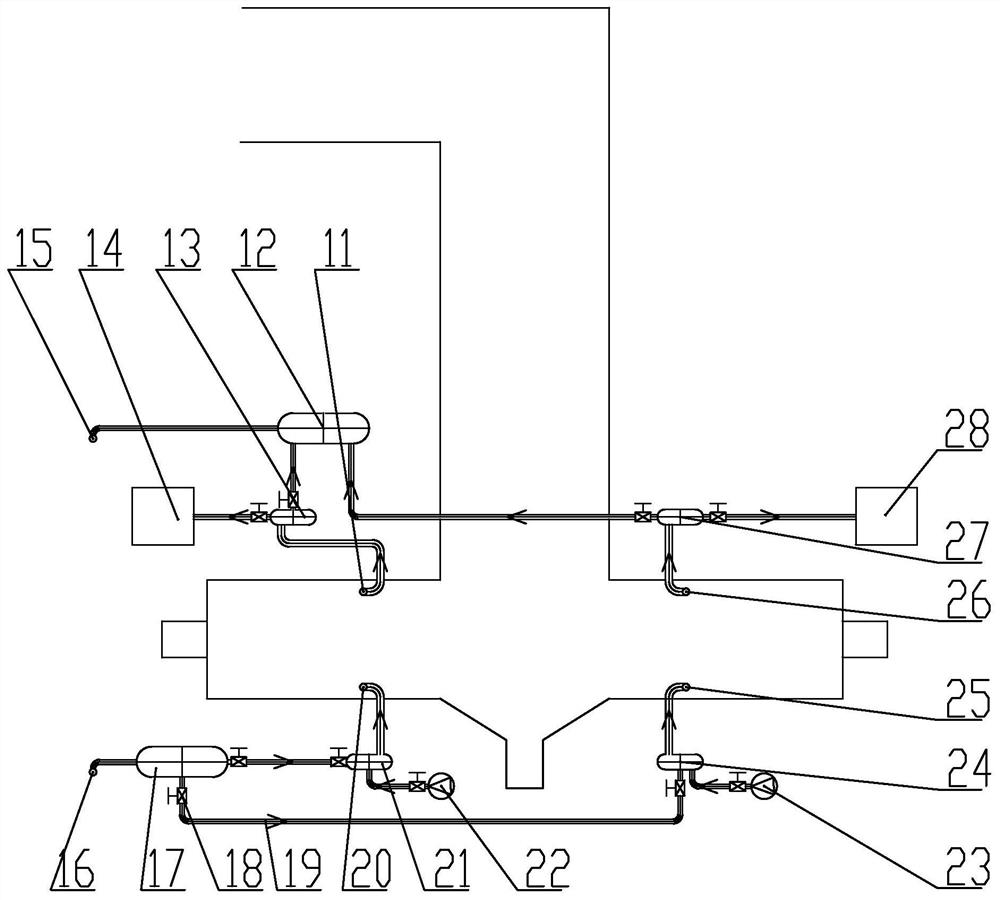

[0035] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further limitation on the industrial pulverized coal boiler described in the first specific embodiment. An industrial pulverized coal boiler with a double-level furnace opposed arrangement described in this embodiment. The steam-water cycle The unit includes No. 1 water wall outlet pipe 11, upper header 12, No. 1 upper grading header 13, No. 1 cooling water tank 14, upper header outlet pipe 15, lower header inlet pipe 16, lower header 17, and connecting branch pipe 19 , No. 1 water wall inlet pipe 20, No. 1 lower stage header 21, No. 1 cooling water pump 22, No. 2 cooling water pump 23, No. 2 lower stage header 24, No. 2 water wall inlet pipe 25, No. 2 water cooling Wall outlet pipe 26, No. 2 upper grading header 27 and No. 2 cooling water tank 28;

[0036] The upper part of the No. 1 horizontal furnace 2 is connected to the input port at the bottom of t...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. This embodiment is a further limitation of the industrial pulverized coal boiler described in the second specific embodiment. An industrial pulverized coal boiler with a double-level furnace opposed arrangement described in this embodiment. The steam-water cycle Each pipeline in the unit is provided with a valve 18;

[0041] In this specific embodiment, a valve 18 is arranged on each pipeline in the steam-water circulation unit to facilitate the control of the steam-water circulation unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com