Integrated cooker with automatic lampblack sensing and stepless air speed adjusting system and control method

A wind speed adjustment and integrated stove technology, which is applied in the direction of oil fume removal, household stoves, heating methods, etc., can solve the problems of inconvenient operation, inability to better adjust the wind speed, and smoke leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

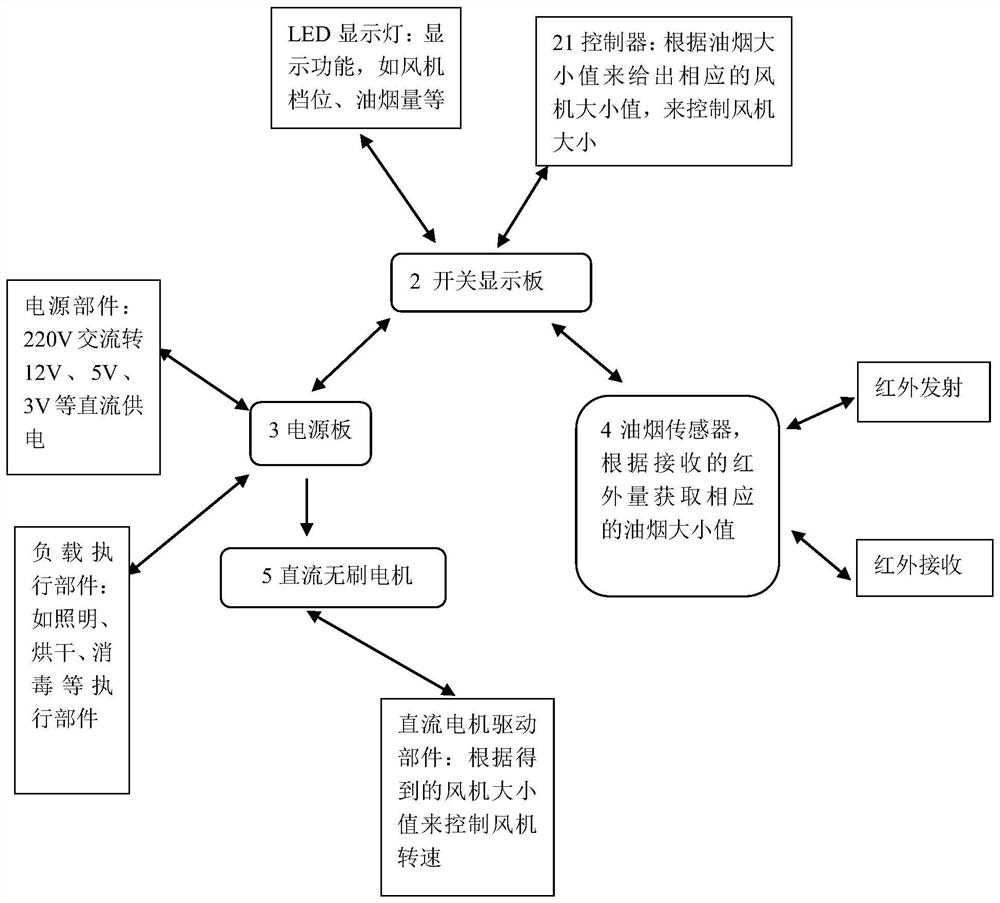

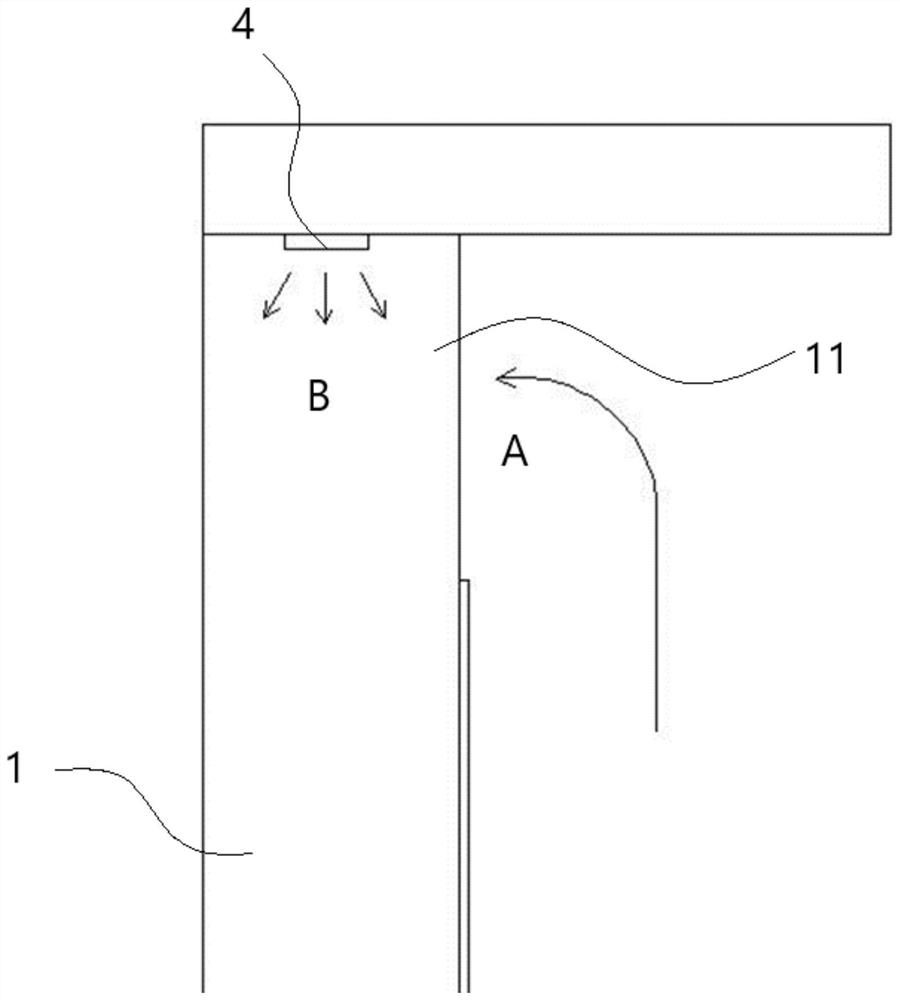

[0031] Embodiment 1 As shown in the figure, the integrated stove with automatic oil fume sensing and stepless wind speed adjustment system according to the present invention includes an integrated stove body 1 and an automatic oil fume sensing and stepless wind speed adjustment system arranged on the integrated stove body 1 , the automatic oil fume sensing and stepless wind speed adjustment system includes a switch display board 2 for controlling the operation of the hood in the integrated stove body, a power supply board 3 for supplying power to the switch display board, and a fume sensor assembly 4 for detecting the size of the oil fume ;

[0032] The switch display panel 2 includes a controller 21, a touch button and an LED display lamp, the control signal input port of the controller is electrically connected to the signal output port of the touch button; the signal output port of the controller is connected to the The control port of the LED display lamp is electrically c...

Embodiment 2

[0040] Embodiment 2 According to Embodiment 1, the control method of the integrated cooker with automatic oil fume sensing and stepless wind speed adjustment system includes the following steps:

[0041] S1 touch switch The touch button on the display board makes the whole integrated stove body and automatic oil fume sensing and stepless wind speed adjustment system in the power-on state;

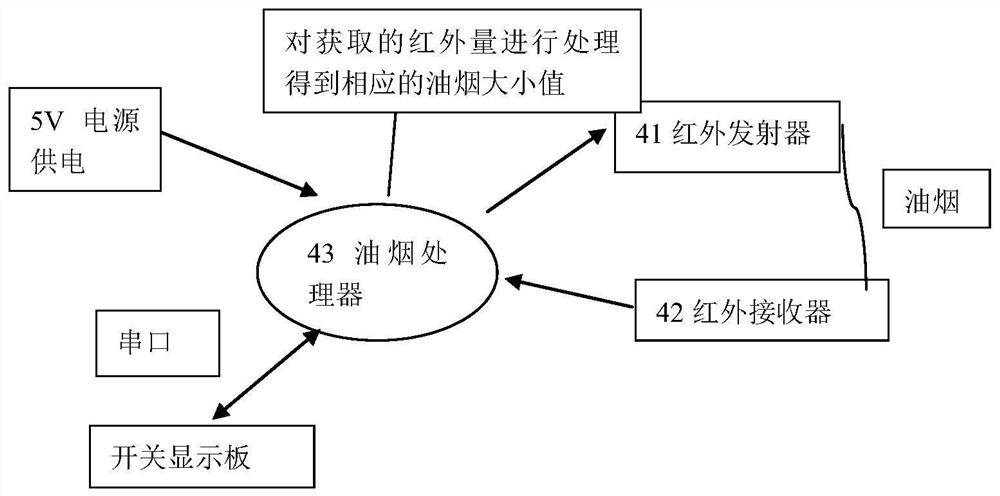

[0042] The oil fume discharged from the S2 cooker passes through the oil fume sensor assembly, and the infrared emitter of the oil fume sensor assembly emits infrared signals from top to bottom, and the infrared signal is partially reflected to the infrared receiver after being interfered by the oil fume;

[0043] The S3 infrared receiver transmits the received infrared signal to the oil fume controller, and the oil fume controller processes the infrared signal and converts it into an oil fume value signal recognizable by the controller, and transmits the obtained oil fume value signal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com