Self-luminous display panel

A display panel, self-luminous technology, applied in the direction of organic semiconductor devices, electrical components, diodes, etc., can solve the problem of difficulty in fully reducing chromaticity changes, and achieve the effect of refinement, reduction of chromaticity changes, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

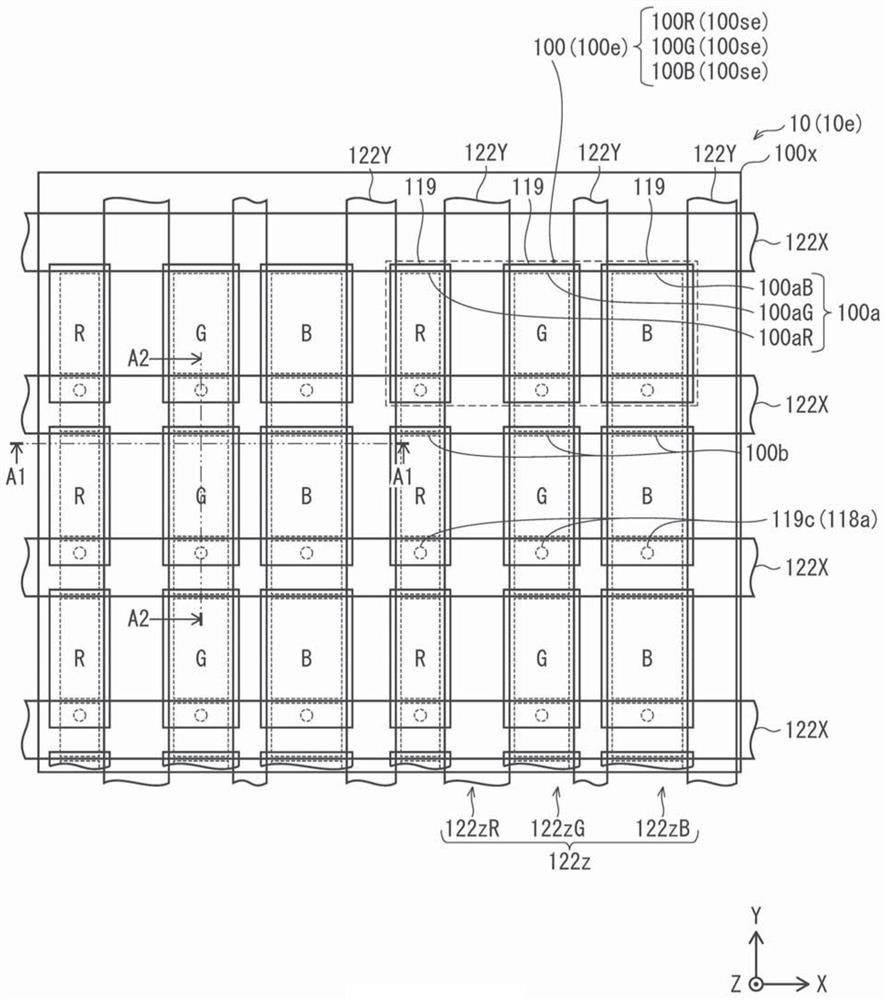

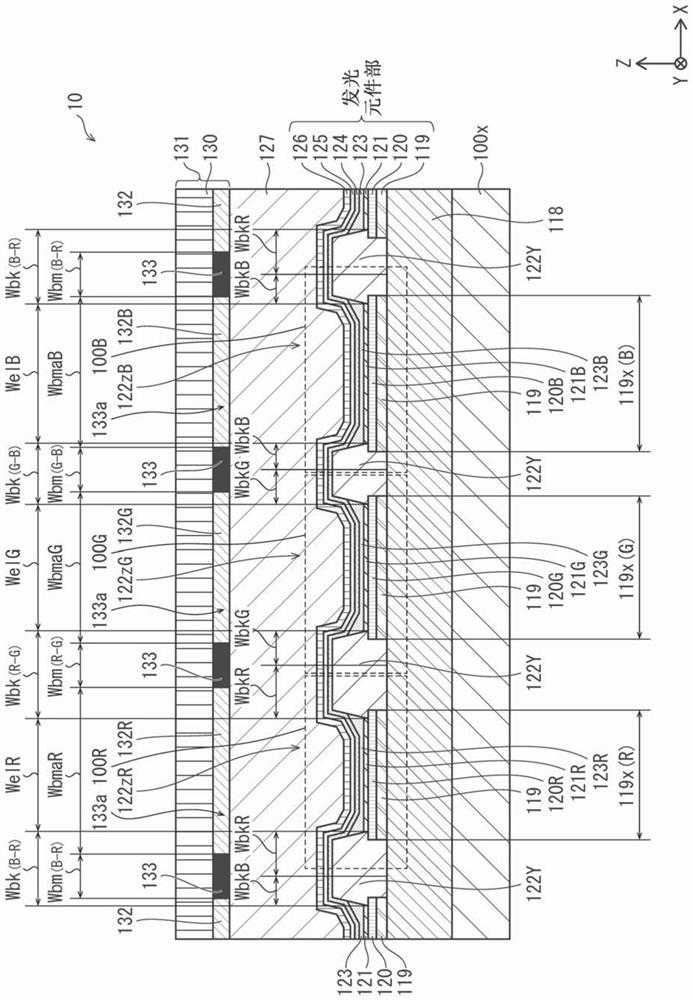

[0250] In the display panel 10 according to the embodiment, the row widths Wbma(R-G), Wbma(G-B), and Wbma(B-R) of the openings 133a in the light-shielding film 133 are related to the light emission of the light-emitting element 100 . Regardless of the color, the row direction width Wbm(R-G), Wbm(G-B), Wbm(B-R) of the gate part between the openings 133a is also independent of the light-emitting color of the light-emitting element 100, etc. price composition. In the display panel 10A according to Modification 1, the widths Wbm(R-G), Wbm(G-B), and Wbm(B-R) in the row direction of the portion configured as the gate between the openings 133 a are also determined by the light-emitting element 100 As a result, the row-wise widths Wbma(R-G), Wbma(G-B), and Wbma(B-R) of the openings 133a in the light-shielding film 133 differ depending on the light-emitting color of the light-emitting element 100, This point is different from the embodiment.

[0251] Figure 14 is the display panel ...

Deformed example 2

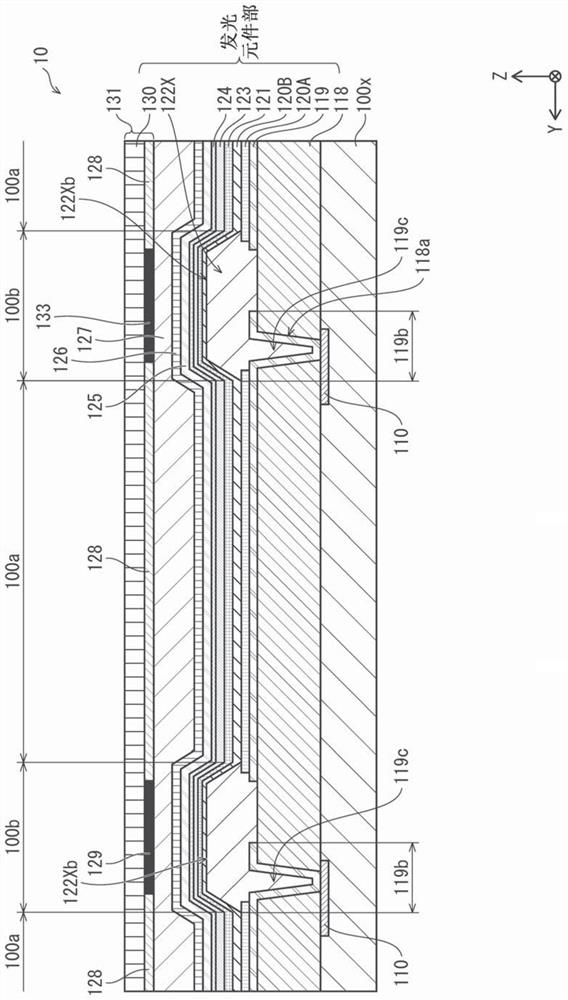

[0254] In the display panel 10 according to the embodiment, as an example, the maximum distance in the emission direction between the light emission reference point of the light emitting element 100B and the edge of the opening 133a of the light shielding film 133 is used as compared with the light emitting elements 100R and G. LB explains the implementation in a longer way. In this embodiment, as described above, the lengths 119 x (B), (G), and (R) in the row direction of the pixel electrodes 119 in the light-emitting elements 100B, 100G, and 100R are configured in the order of the light-emitting elements 100B, 100G, and 100R. From large to small, the light-shielding rate of the light-emitting element 100B is the smallest. On the other hand, by adopting the above structure in the display panel 10, the light-shielding ratio of the light-emitting element 100 whose pixel electrode 119 has the largest length in the row direction is increased, thereby effectively compensating for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com