Cable separating and stripping device

A technology for cables and cable sheaths, which is applied in the field of cable separation and stripping devices, can solve problems such as violent operations and scratches on the limbs of staff, and achieve the effects of improving efficiency, avoiding damage, and improving rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

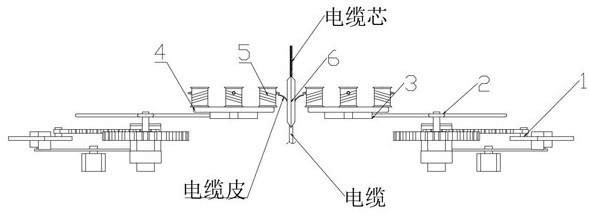

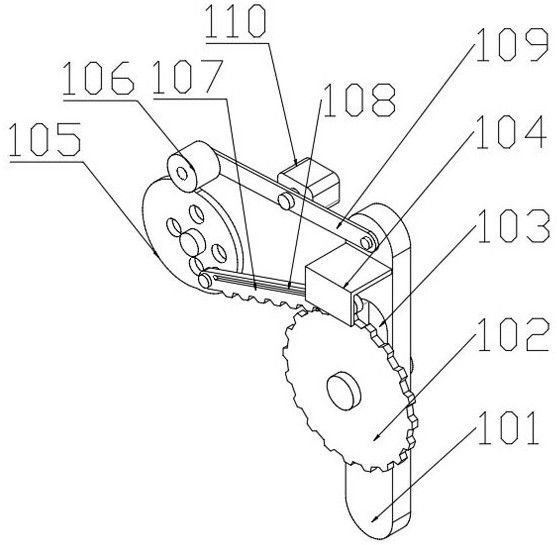

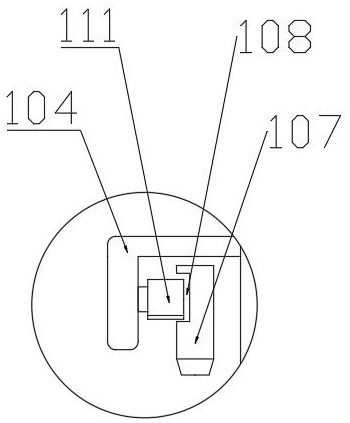

[0022] see Figure 1-2 , as an embodiment, a cable separation and stripping device, including a ring stripping knife 6 for cutting the cable sheath, the side of the ring stripping knife 6 is provided with a winding mechanism and a driving mechanism 1, and the winding mechanism includes A plurality of reels 5, the bottom of the reel 5 is provided with a drive mechanism 1 for driving the reel 5 to convert the working position; the number of the drive mechanism 1 is two, and the drive mechanism 1 With regard to the symmetrical arrangement of the cables, the drive mechanism 1 includes a moving plate 101, a gear 102, a rack 107 and a cam 105. A limiting groove 103 is provided on the moving plate 101, and a rotating shaft is pierced in the limiting groove 103. One end of the rotating shaft is fixedly connected to the gear 102, and the other end is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com