Efficient and environment-friendly stainless steel product polishing technology

A stainless steel, environmentally friendly technology, applied in the direction of fixed filter elements, filter separation, membrane filters, etc., can solve the problems of lack of auxiliary feeding mechanism, reduce the polishing quality of stainless steel workpieces, lack of auxiliary stirring structure, etc., to achieve optimal placement and mixing process, the process of placing and fixing is convenient, and the effect of improving the polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

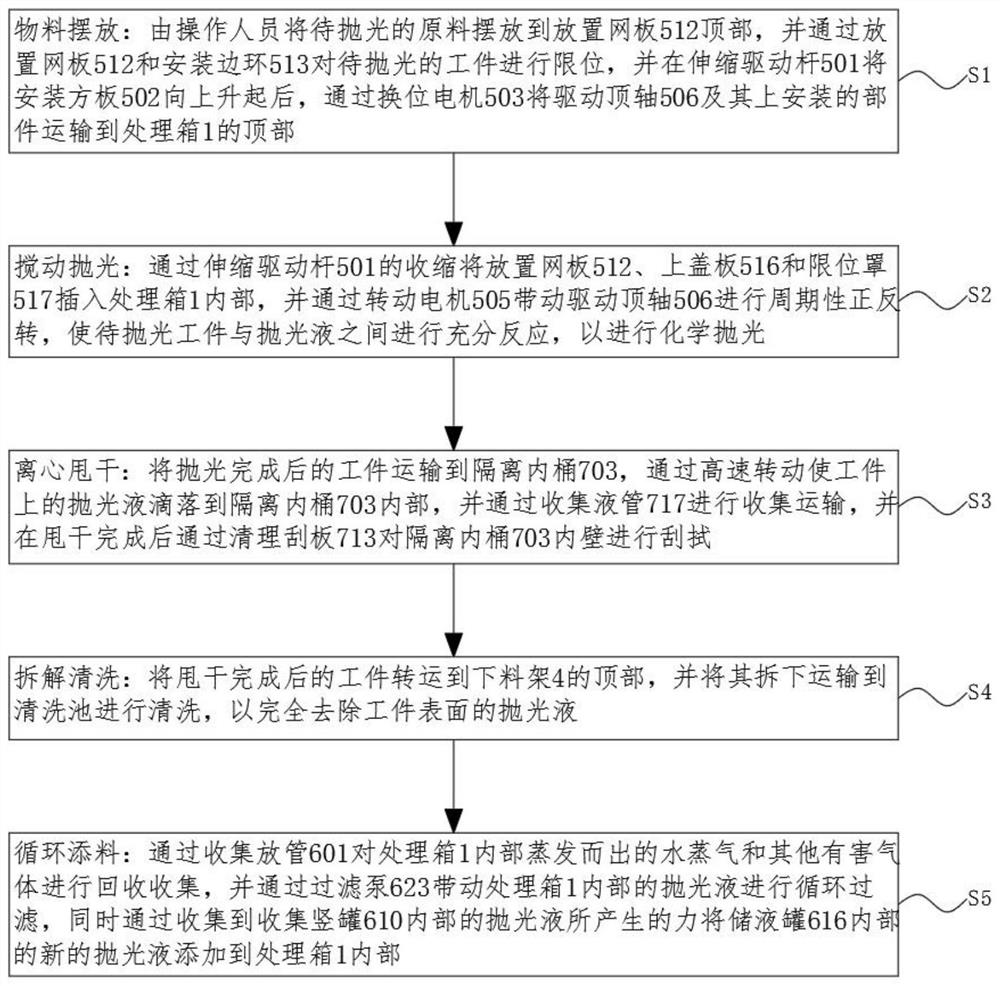

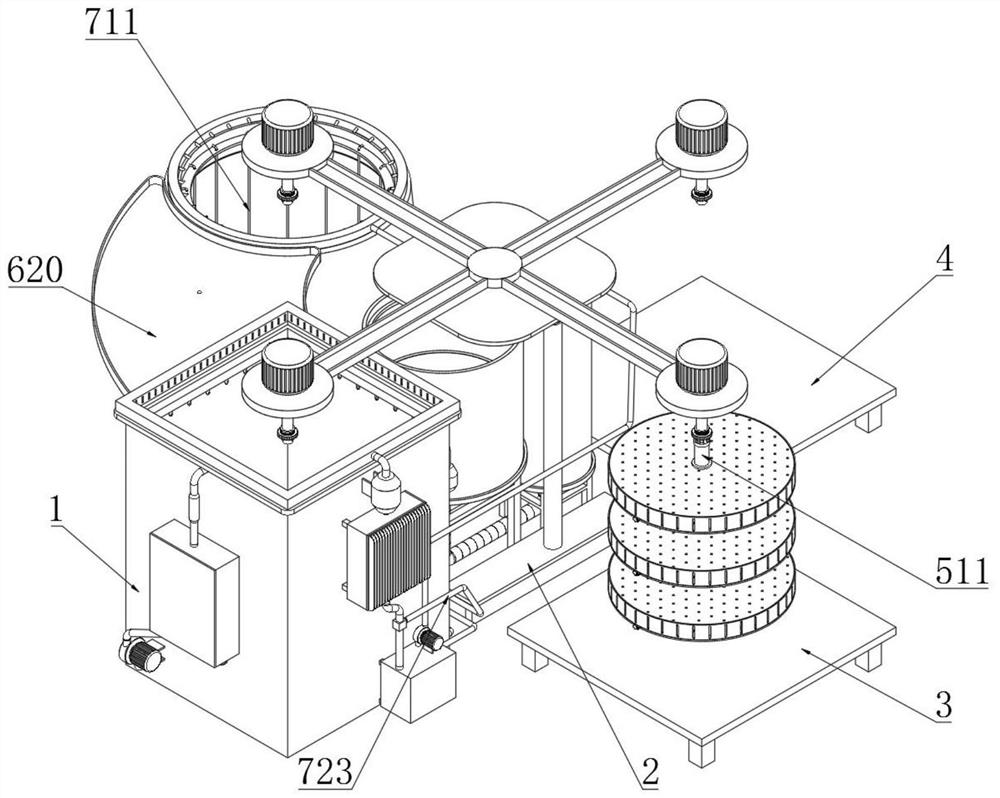

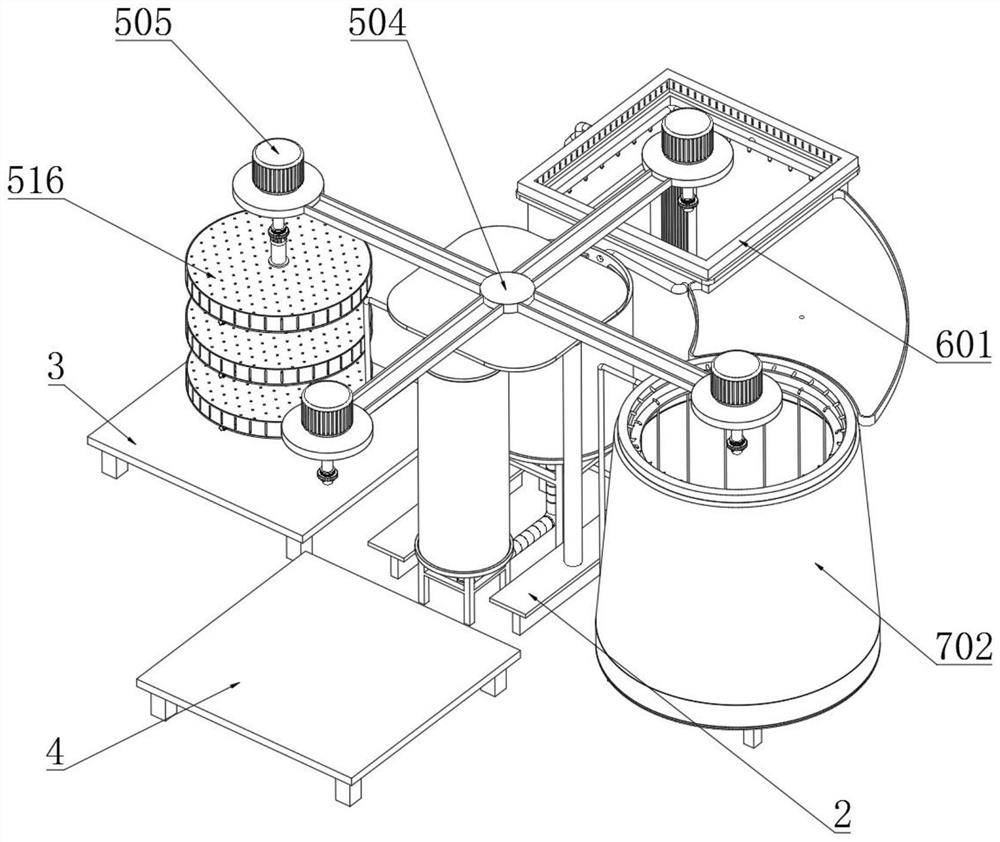

[0044] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a highly efficient and environmentally friendly polishing process for stainless steel products, comprising the following steps:

[0045] S1. Material placement: the operator puts the raw materials to be polished on the top of the placement screen 512, and limits the workpiece to be polished by placing the screen 512 and installing the edge ring 513, and installs it on the telescopic drive rod 501. After the square plate 502 rises upwards, the top shaft 506 and the parts installed on it are transported to the top of the processing box 1 by the transposition motor 503;

[0046] S2. Stirring and polishing: Insert the screen plate 512, upper cover plate 516 and limit cover 517 into the processing box 1 through the contraction of the telescopic drive rod 501, and drive the top shaft 506 to perform periodic forward and reverse rotation through the rotating motor 505, Fully react betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com