A connection method and connection mechanism of a stainless steel hose and a radio frequency connector

A technology of radio frequency connector and connection method, applied in electrical components and other directions, can solve the problems of inability to perform fixed buried wire protection, damage to cable components, signal shielding failure, etc., so as to reduce cable damage, extend service life, and avoid cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

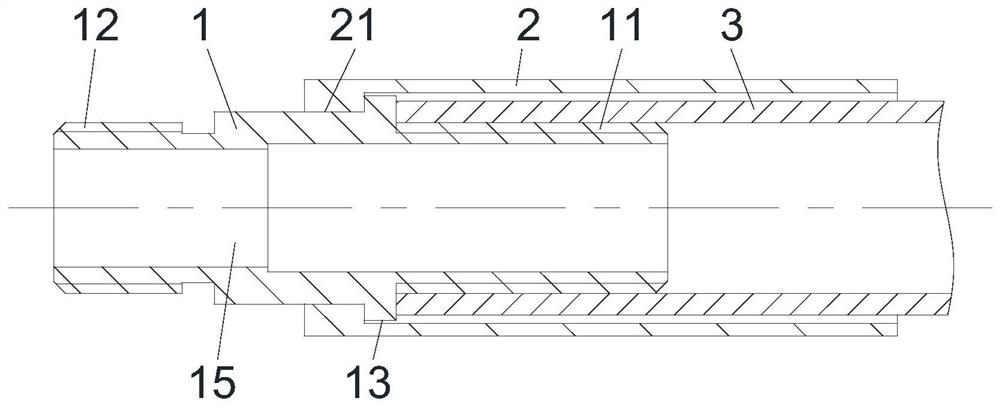

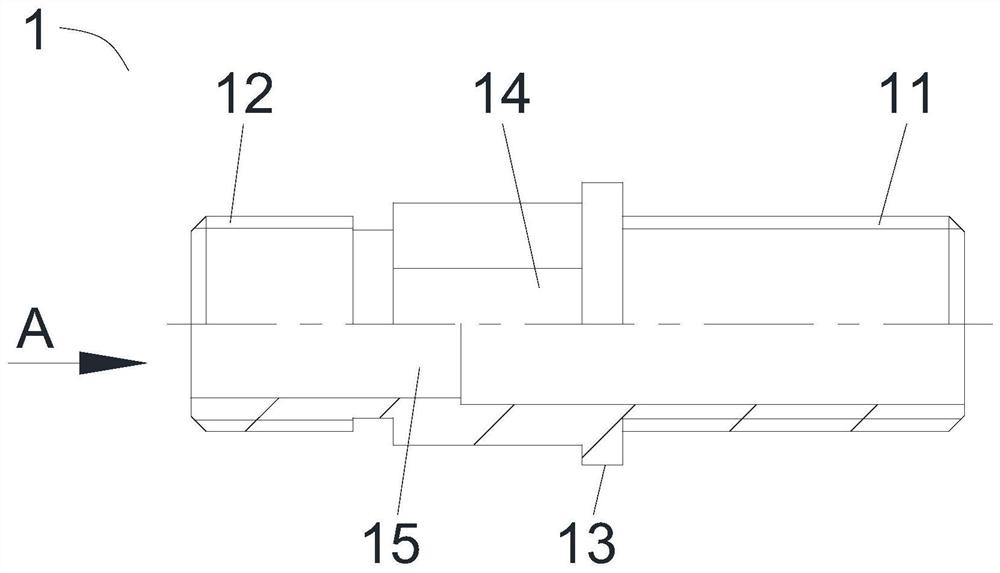

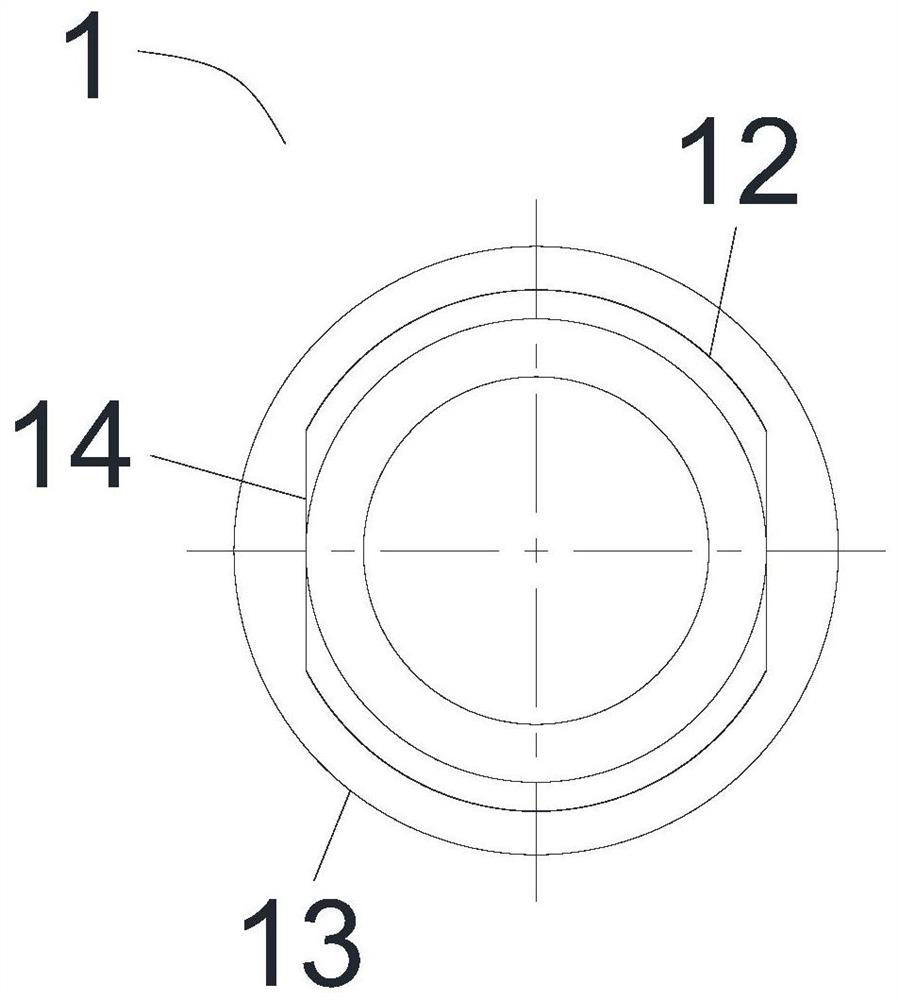

[0029] Such as Figure 1 to Figure 5 As shown, a connection method of a stainless steel hose and a radio frequency connector and its connection mechanism, including the following steps:

[0030] Step 1: Set the stainless steel hose 3 on the non-slip thread 11 of the connecting nut 1;

[0031] Step 2: Install the pressure ring 2 from the end of the connection thread 12 of the connection nut 1, and set it on the stainless steel hose 3, and align the inner locking step 21 of the pressure ring 2 with the flat position 14 of the connection nut 1, and press it in The pressure ring 2 fits the end face of the inner locking step 21 with the limit flange 13, and the end face of the inner hole of the pressure ring 2 exceeds the end face of the connecting thread 12;

[0032] Step 3: Flatten at the position corresponding to the anti-slip thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com