Structure for ensuring output precision of split-type rotary transformer

A rotary transformer and sub-package technology, which is applied in the direction of transformer, output power conversion device, AC power input conversion to AC power output, etc., can solve the problems of low installation accuracy, low reliability, and reduced output accuracy of the resolver. Achieve the effect of strengthening anti-interference performance and ensuring dynamic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

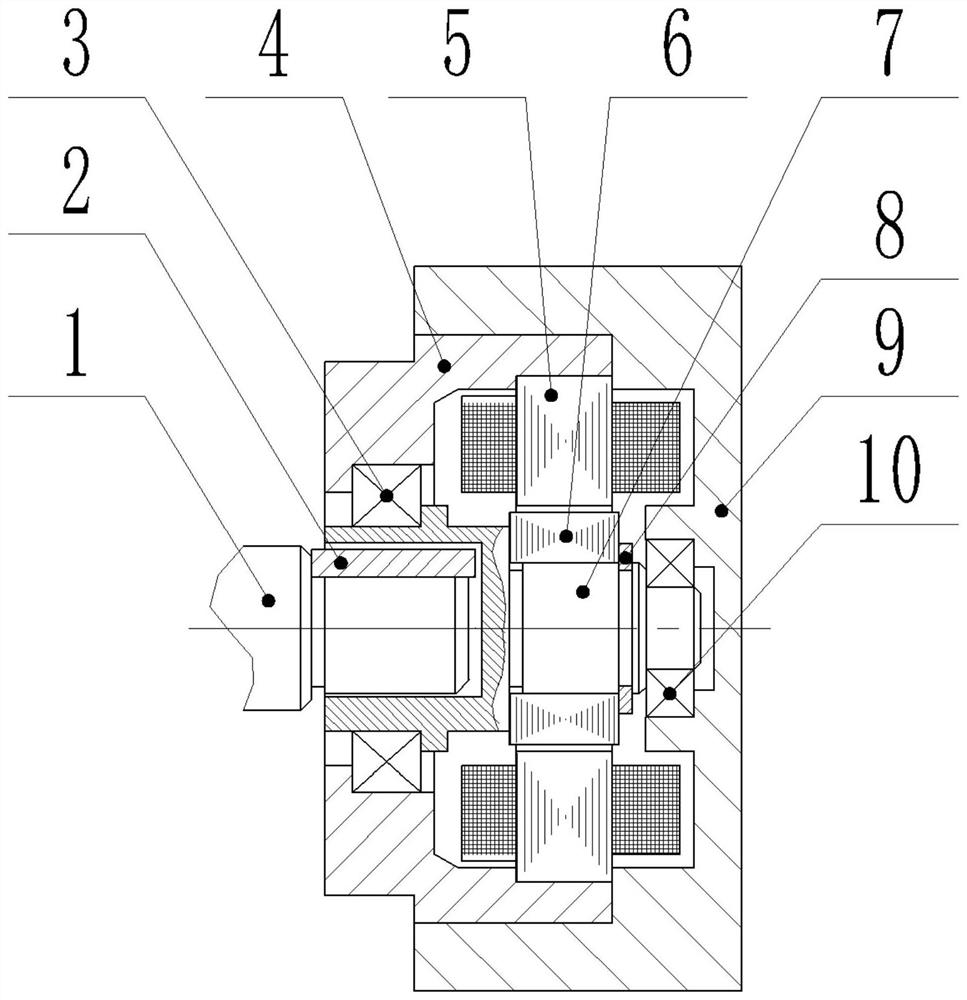

[0019] This embodiment discloses a structure for ensuring the output accuracy of a sub-package resolver, including a main shaft 1, a key 2, a bearing I3, a resolver mounting frame 4, a resolver stator 5, a resolver rotor 6, a resolver installation shaft 7, Back cover 9 and bearing II10.

[0020] The two sides of the resolver mounting frame 4 are marked as A side and B side respectively, and the cavity S inside the resolver mounting frame 4 runs through the A side and the B side. The main shaft 1 is arranged on the A side of the resolver mounting frame 4, and the back cover 9 is fastened on the B side of the resolver mounting frame 4 by using a seam, which can ensure the concentricity between the back cover 9 and the resolver mounting frame 4.

[0021] see figure 1 , the resolver stator 5, the resolver rotor 6 and the resolver mounting shaft 7 are all installed in the cavity S, the resolver mounting shaft 7 is connected to the inner wall of the resolver mounting frame 4 throug...

Embodiment 2

[0024] This embodiment discloses a structure for ensuring the output accuracy of a sub-package resolver, including a main shaft 1, a key 2, a bearing I3, a resolver mounting frame 4, a resolver stator 5, a resolver rotor 6, a resolver installation shaft 7, Back cover 9 and bearing II10.

[0025] The two sides of the resolver mounting frame 4 are marked as A side and B side respectively, and the cavity S inside the resolver mounting frame 4 runs through the A side and the B side. The main shaft 1 is arranged on the side A of the resolver mounting frame 4 , and the back cover 9 is fastened on the side B of the resolver mounting frame 4 .

[0026] see figure 1 , the resolver stator 5, the resolver rotor 6 and the resolver mounting shaft 7 are all installed in the cavity S, the resolver mounting shaft 7 is connected to the inner wall of the resolver mounting frame 4 through the bearing I3, and the resolver mounting shaft 7 Be connected on the inner wall of back cover 9 by bearin...

Embodiment 3

[0029] The main structure of this embodiment is the same as that of Embodiment 2, further, refer to figure 1 , the resolver rotor 6 is fixed on the resolver installation shaft 7 through a retaining ring 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com