Anti-impact dense ball static pressure proportion control mixing bearing

A technology of proportional control and dense beads, which is applied in the field of measuring tools to achieve the effect of solving the problem of easy damage of dense beads, high measurement accuracy and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

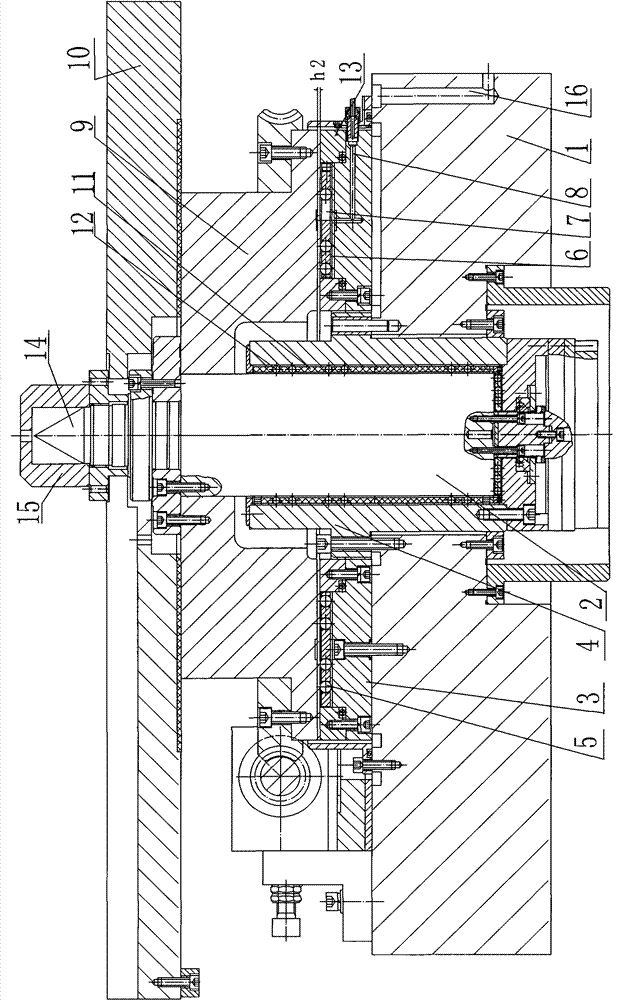

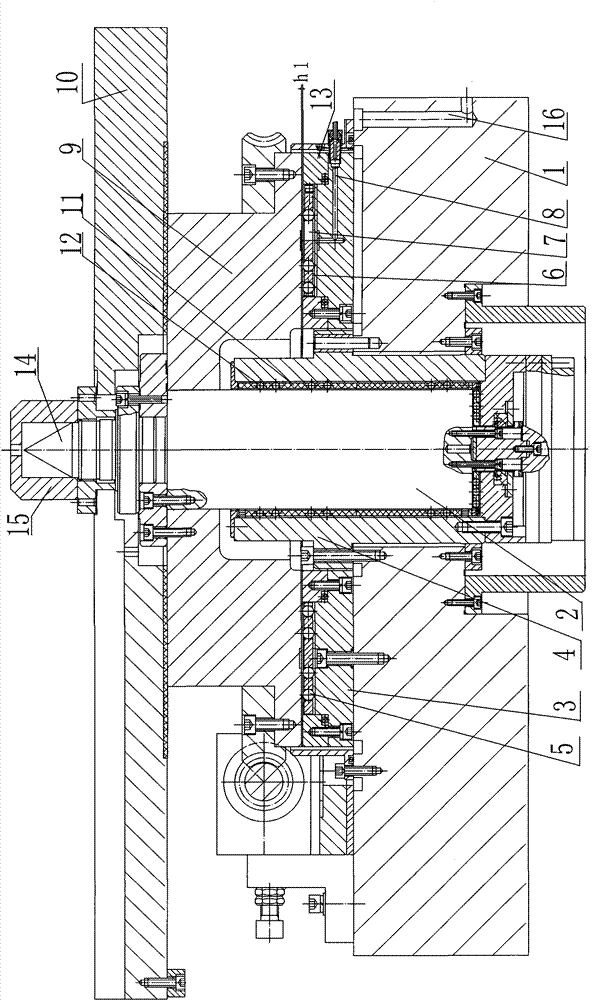

[0024] Anti-shock dense ball static pressure proportional control hybrid bearing, its composition includes: base 1, said base 1 is equipped with main shaft 2 and static pressure ball table 3, said main shaft 2 is covered with shaft sleeve 4, said The static pressure ball table 3 is equipped with a rolling dense ball bearing 5 and a ball cage 6. There is a space 7 for hydraulic oil between the rolling dense ball bearing 5 and the ball cage 6. The lower end of the ball cage 6 is It is connected to the hydraulic oil inlet hole 8, the upper end of the static pressure ball table 3 is connected to the turntable 9, the turntable 9 is connected to the pressure receiving tray 10, and the rolling dense ball bearing has one set.

[0025] The anti-shock dense bead static pressure proportional control hybrid support, the dense bead cage 11 is installed between the main shaft 2 and the bushing 4, and the dense bead cage 11 is equipped with a rolling dense bead bearing 12.

[0026] The anti-...

Embodiment 2

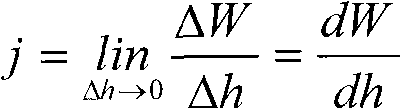

[0030] According to the anti-shock dense ball static pressure proportional control hybrid bearing described in Embodiment 1, the hydraulic oil inlet hole connected to the lower end of the ball cage is vertical, and the vertical hydraulic oil inlet hole is connected to the horizontal The hydraulic oil inlet hole; the hydraulic system has a variety of pressure and flow, which is completed by the frequency conversion motor to drive the hydraulic pump. Different pressures are set by the proportional control relief valve. Before measurement or processing, as long as the weight of the workpiece is input into the computer, the computer will give corresponding instructions to the proportional control valve, and the proportional control valve will automatically adjust the pressure to the corresponding gear, so that the hydraulic pressure generated The upward buoyancy overcomes a part of the weight (this upward buoyancy varies with the weight of the workpiece), so that the force on the r...

Embodiment 3

[0032] According to the anti-shock ball static pressure proportional control hybrid support described in Embodiment 1, the upper end of the base is provided with an oil return hole 16 vertically connected to the horizontal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com