Planetary combined cleaning ball

A technology for cleaning balls and planets, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small applicability of cleaning balls, and achieve the effect of saving water source, preventing shaking and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

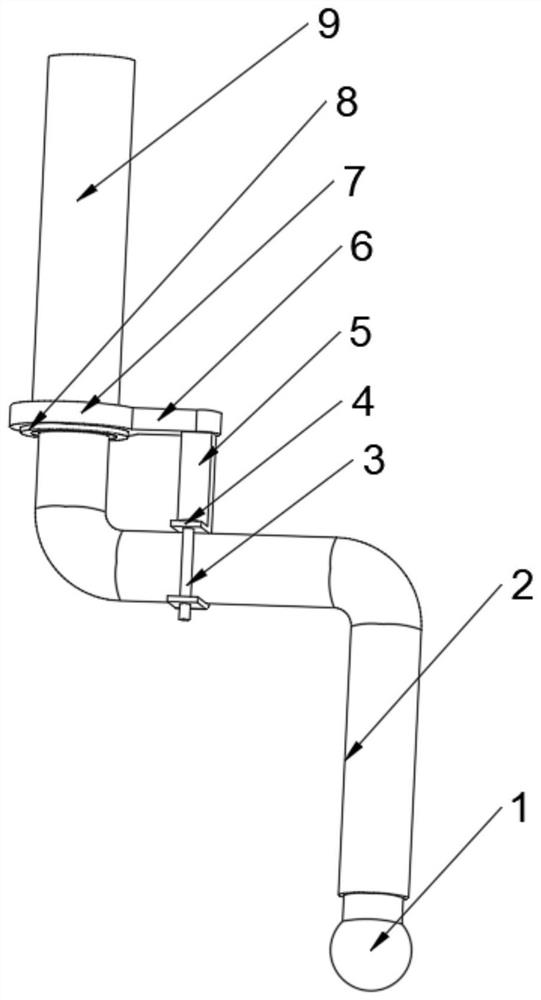

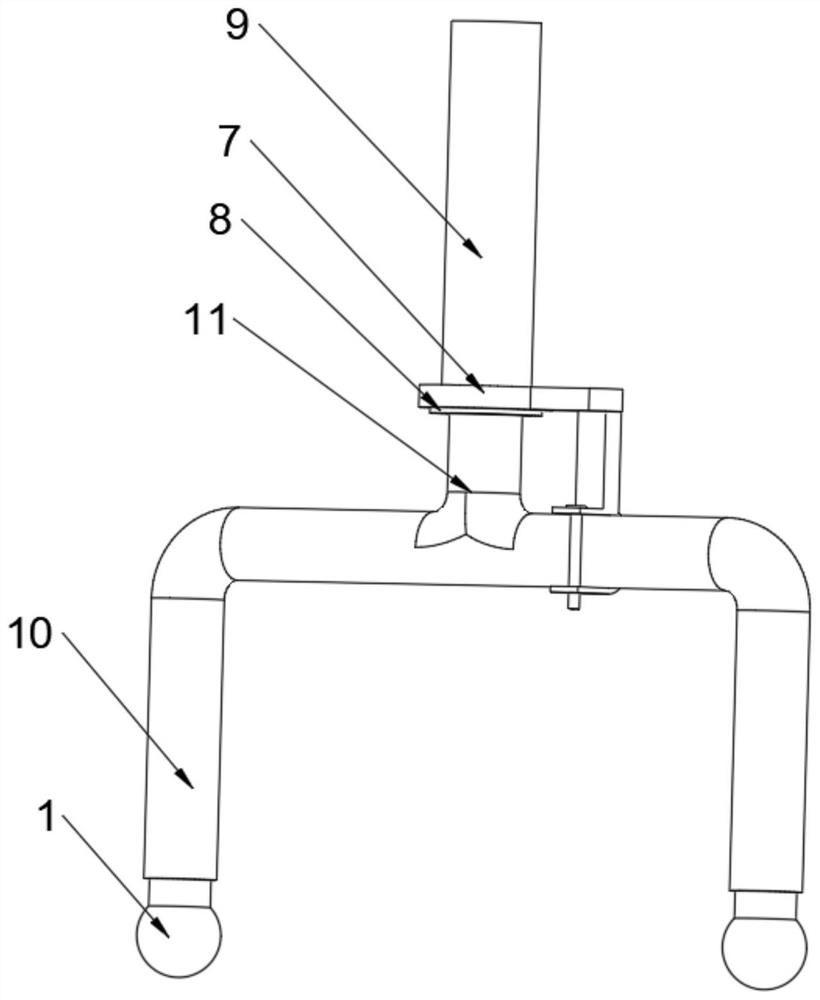

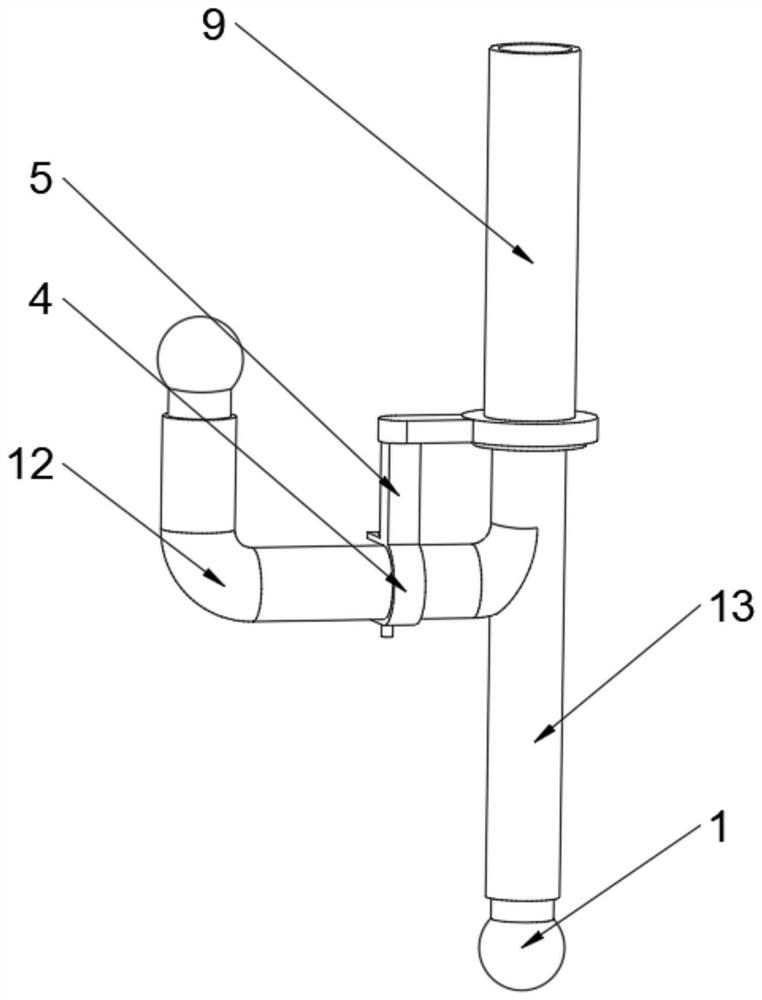

[0023] Please refer to Figure 1-Figure 4 As shown, the present invention provides a planetary combination cleaning ball, including a water inlet pipe 9, the bottom end of the water inlet pipe 9 is provided with a water outlet pipe that is movably connected with the water inlet pipe 9, and the other end of the water outlet pipe is provided with a cleaning device that is connected to the water outlet pipe through a fixed part. Ball 1, the water outlet pipe includes the first rotating pipe 2, the second rotating pipe 10, the third rotating pipe 12, the vertical pipe 13 and the fourth rotating pipe 14, and the outer side of the water inlet pipe 9 is provided for supporting the third rotating pipe 12 support mechanism;

[0024] When it is necessary to clean the tank environment, different types of outlet pipes are selected to be combined with the cleaning ball 1, so that it is suitable for tank environments of different steels, and the rotation power of the outlet pipe itself come...

Embodiment 2

[0034] Please refer to figure 1 As shown, the other parts of this embodiment 2 are the same as the implementation of embodiment 1. The difference is that the present invention provides a planetary combination cleaning ball. The support mechanism includes a support ring 8, and the support ring 8 is fixedly installed on the outer surface of the water inlet pipe 9. At the edge, the outer side of the water inlet pipe 9 is provided with a collar 7 that is movably connected to the water inlet pipe 9. The outer side of the collar 7 is provided with a cross bar 6, and the bottom surface of the other end of the cross bar 6 is provided with a connecting rod 5. The other end is provided with a snap ring 4 engaged with the outlet pipe, and the other end of the snap ring 4 is pierced with a positioning pin 3;

[0035] When the support mechanism of this device is used, the collar 7 is set on the outside of the water inlet pipe 9, the collar 7 is supported by the support ring 8, the collar 7...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap