Preparation method of aluminum alloy material for flux-free gas-shielded brazing

An aluminum alloy material, gas shielding technology, applied in welding/cutting medium/material, welding equipment, metal processing equipment, etc., can solve the problems of the influence of heat dissipation performance parameters, the influence of connection strength, etc., to improve the milling surface accuracy and milling surface Efficiency, improved finished product quality, the effect of accelerating foil rolling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

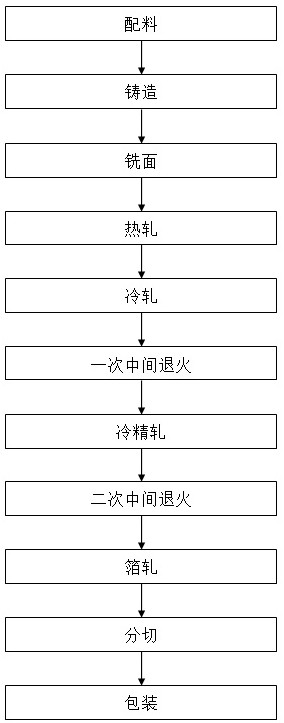

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] Such as figure 1 Shown is a preparation method of an aluminum alloy material for flux-free gas shielded brazing provided by the present application, which includes the following steps:

[0033] 1) Ingredients: Prepare the raw materials for making gas shielded brazing materials according to the preset mass ratio, and record the corresponding mass ratio of each component selected in this batch;

[0034] 2) Casting: cast the prepared raw materials into castings;

[0035] 3) Face milling: Rough milling and fine milling on the surface of the casting to remove burrs and particles attached to the surface of the casting:

[0036] 4) Hot rolling: the milled c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com