Tool special for disassembling and assembling aircraft sensor

A special tool and sensor technology, applied in the aviation field, can solve the problems that the sleeve cannot be inserted into the slot hole of the fixing nut, the sensor space is small, and the force cannot be applied to the slot hole, so as to achieve the effect of simple structure, exquisite design and guaranteed fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

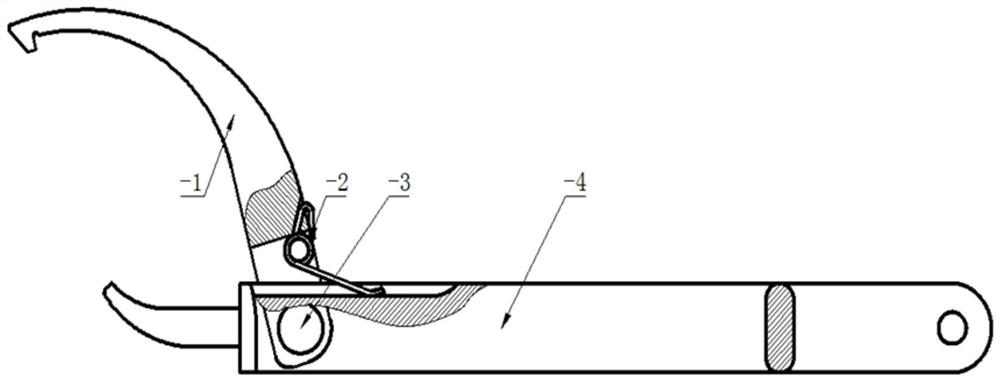

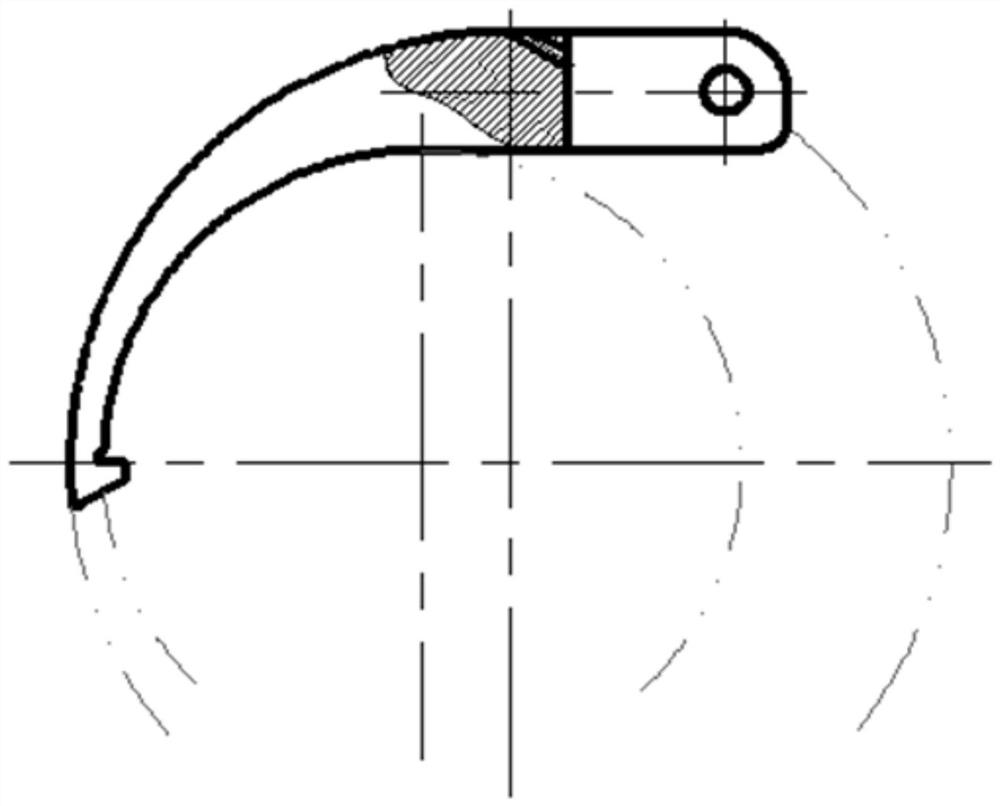

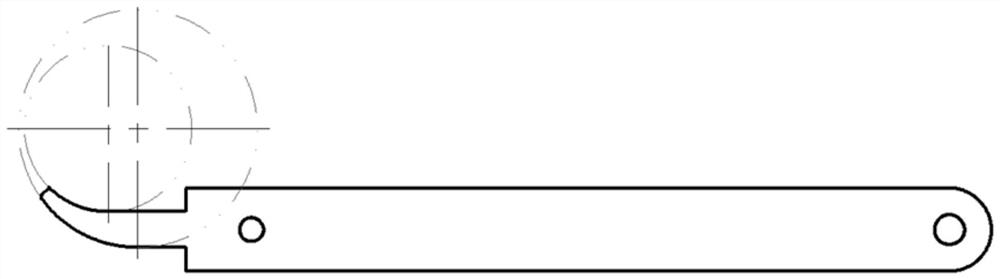

[0023] A special tool for disassembly and assembly of aircraft sensors, such as figure 1 As shown, including movable tooth 1, torsion spring 2, positioning pin 3 and fixed tooth 4; as figure 2 It is the specific figure of the active tooth, such as image 3 It is the specific figure of the fixed tooth.

[0024] The movable tooth 1 and the fixed tooth 4 are connected by a positioning pin 3, and the opening and closing angle of the two is adjusted by a torsion spring 2;

[0025] The fixed tooth 4 is an integral structure composed of the left end and the right end handle, on which there are positioning pin holes and torsion spring fixing holes near the left end; the left end is used for fixing the nut, and the arcs of the inner and outer edges are different Center, the arc center distance is 5mm, this design can effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com