Industrial robot remote monitoring diagnosis system and method based on 5G

An industrial robot and remote monitoring technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high maintenance costs, long time, economic losses, etc., and achieve the effect of improving maintenance progress and good scalability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0017] Using ModbusTCP communication, the industrial robot is connected to the cloud server through Ethernet, and remote online fault diagnosis can be performed through the industrial APP, so as to realize remote analysis and diagnosis of robot faults, remote guidance, and assist maintenance personnel to perform local maintenance on industrial robots Operations, thereby greatly reducing the downtime of industrial robots and equipment on-site troubleshooting time, while reducing the cost of equipment maintenance. In addition, a series of functions such as remote upgrade service of industrial robot software and remote control of industrial robots can be realized through remote operation.

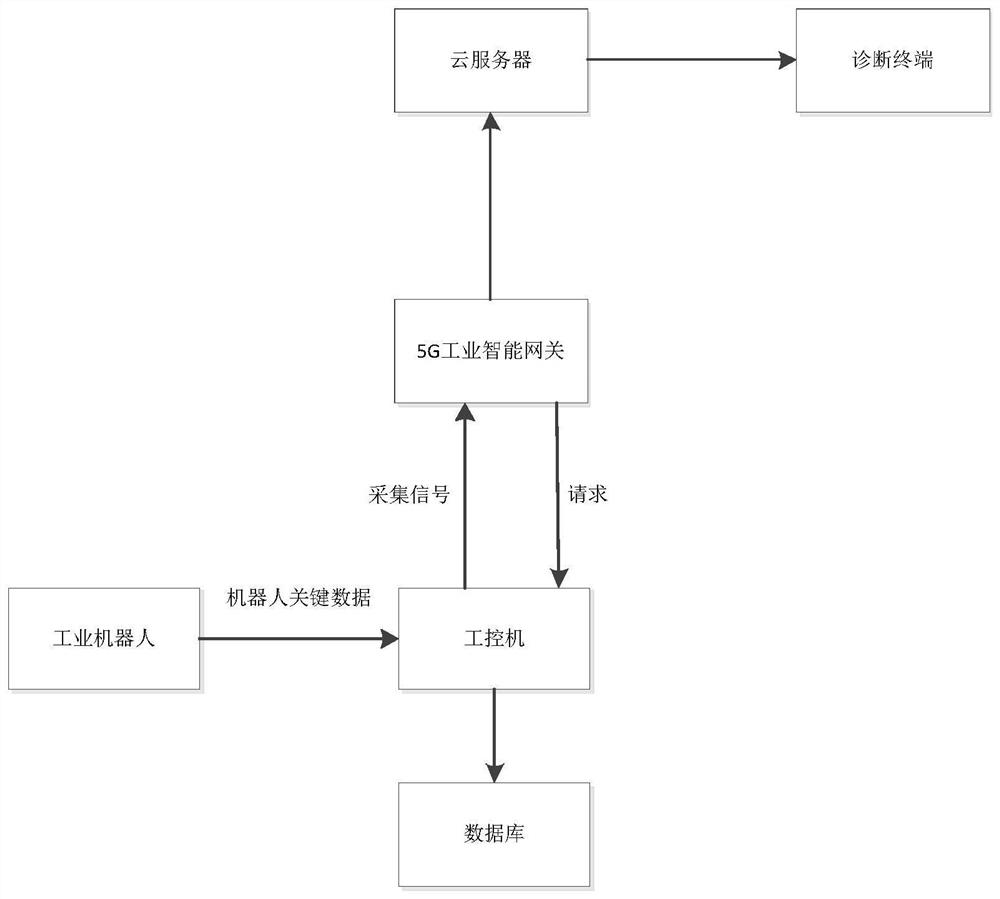

[0018] A 5G-based remote monitoring and diagnosis system for industrial robots, including a 5G industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com