Exhaust structure of nuclear fuel processing mold

A technology for processing molds and nuclear fuel, applied in the field of exhaust structure of nuclear fuel processing molds, can solve the problems of easily damaged molds, inability to compact, difficult to grasp the size of the gap, etc., and achieves the effect of enhancing structural strength and facilitating disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

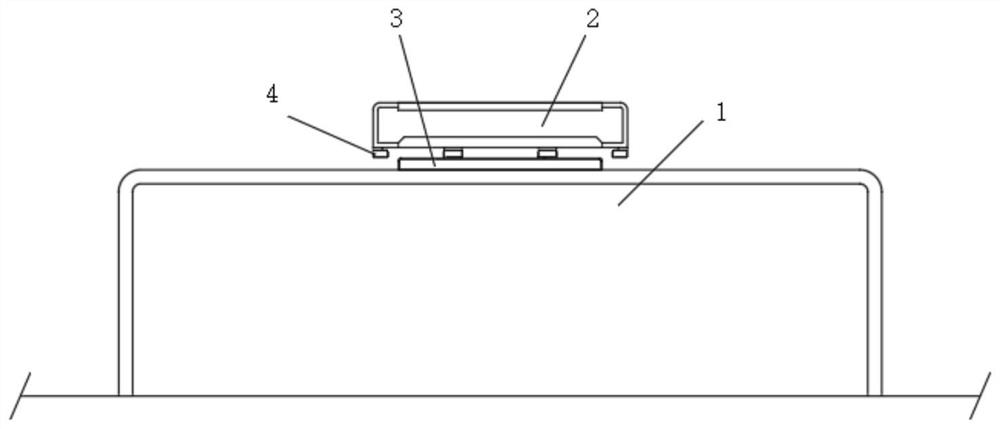

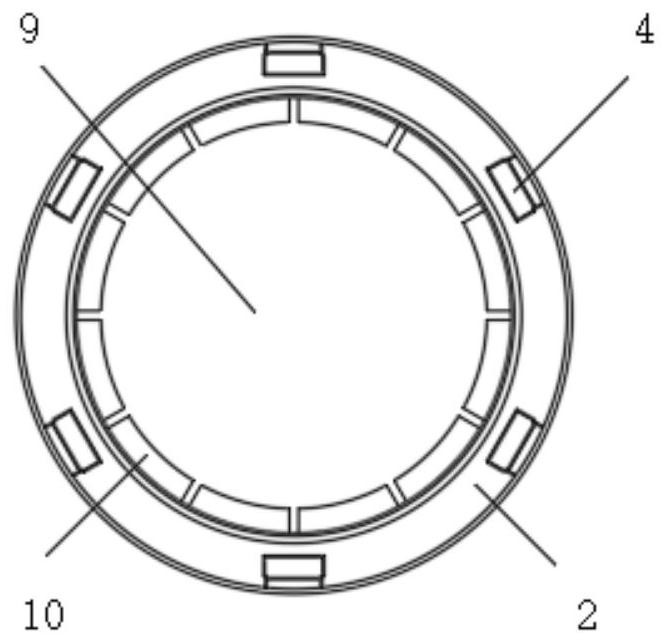

[0028] Please refer to figure 1 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a kind of exhaust structure of nuclear fuel processing mold, comprises mold body 1, and the top surface of mold body 1 is provided with mold hole 5, and the top port of mold hole 5 is covered and fixed with cover sleeve 2, and cover sleeve 2 The top surface is provided with a circular hole 9, which communicates with the inside of the die hole 5, and the inner wall of the port of the circular hole 9 is provided with a storage groove 11, and the inside of the storage groove 11 is provided with a rubber sheet 10, and the inside of the rubber sheet 10 The braided layer 14 is intertwined and fixed, and the outer surface of the rubber sheet 10 is fixedly connected with a wearing layer 15. The wearing layer 15 is designed to have at least two layers, and the colors between adjacent wearing layers 15 are different. A fixed shaft 12 is fixedly connected, and a return spring ...

Embodiment 2

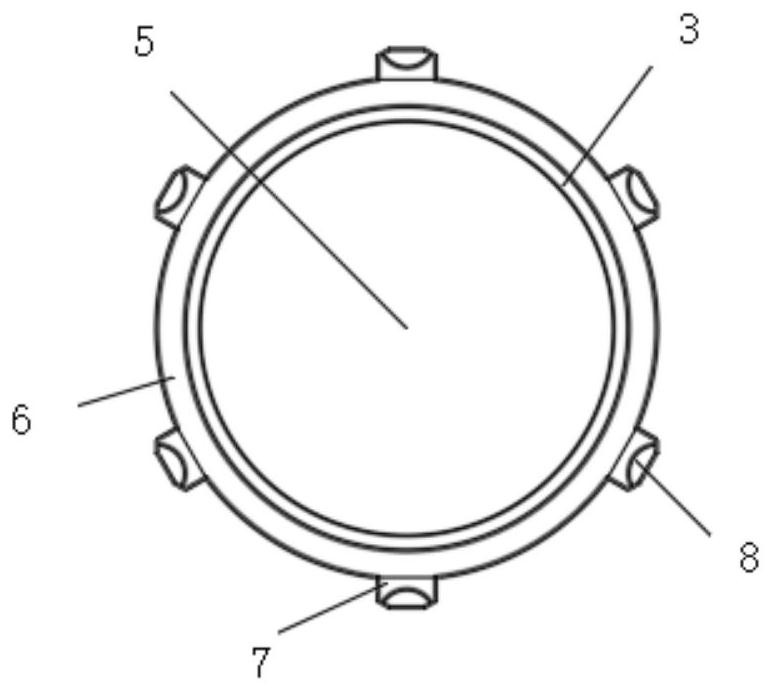

[0031] Please refer to figure 1 , figure 2 , image 3 and Figure 6 As shown, the present invention provides a kind of exhaust structure of nuclear fuel processing mould, comprises mold body 1, and the top surface of mold body 1 is provided with mold hole 5, and the port inner wall of mold hole 5 is fixedly connected with seal ring 3, and the mouth of mold hole 5 The outer wall of the port is provided with an annular groove 6, and the inner wall of the port of the annular groove 6 is provided with a bayonet 7, and the port of the bayonet 7 is fixed on the top surface of the mold body 1, and the inner wall of the bayonet 7 is fixedly connected with a limit buckle 8, and the limit buckle The outer contour of 8 is an arc-shaped structure, the top port of the die hole 5 is covered and fixed with a cover 2, and the bottom outer end of the cover 2 is fixedly connected with a fixing buckle 4, which corresponds to the bayonet 7, and the fixing buckle 4 The penetrating bayonet 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com