Three-phase separator

A three-phase separator and main body technology, which is applied in the field of water treatment, can solve the problems of easy mud running, poor solid and liquid separation effect, etc., and achieve the effect of complete separation, reduced impact and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be used herein, not to be construed as limiting the invention.

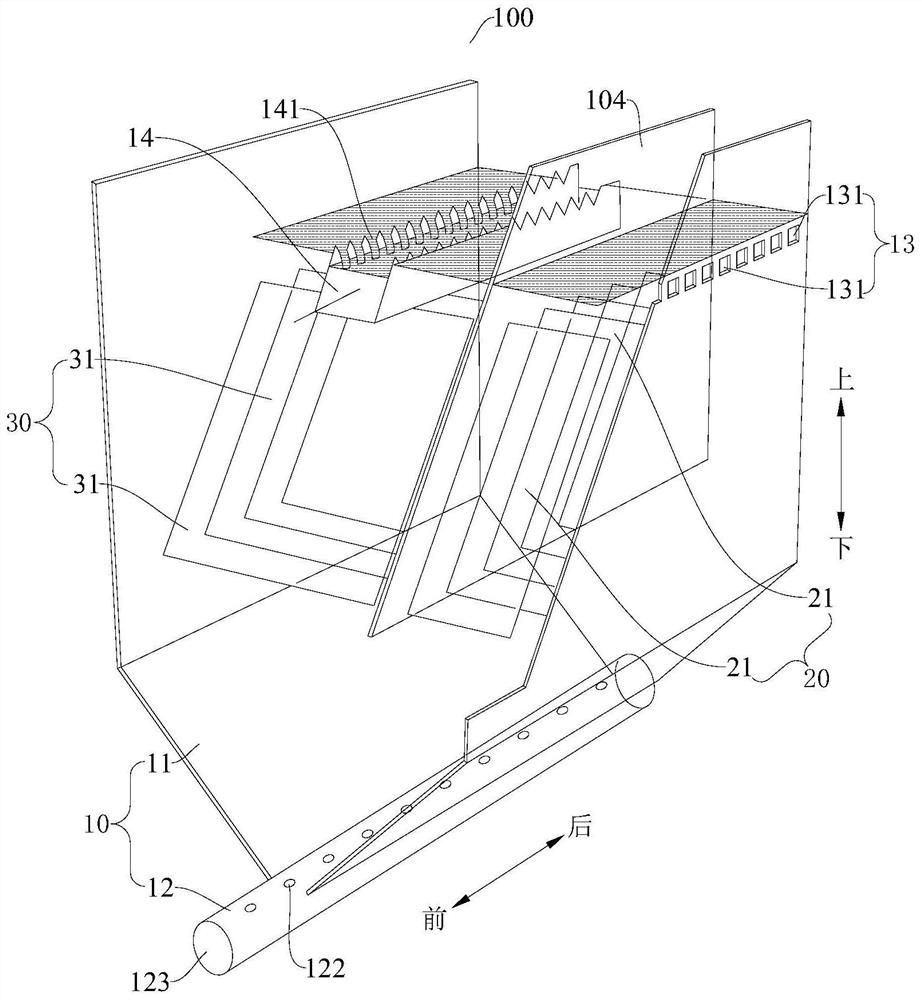

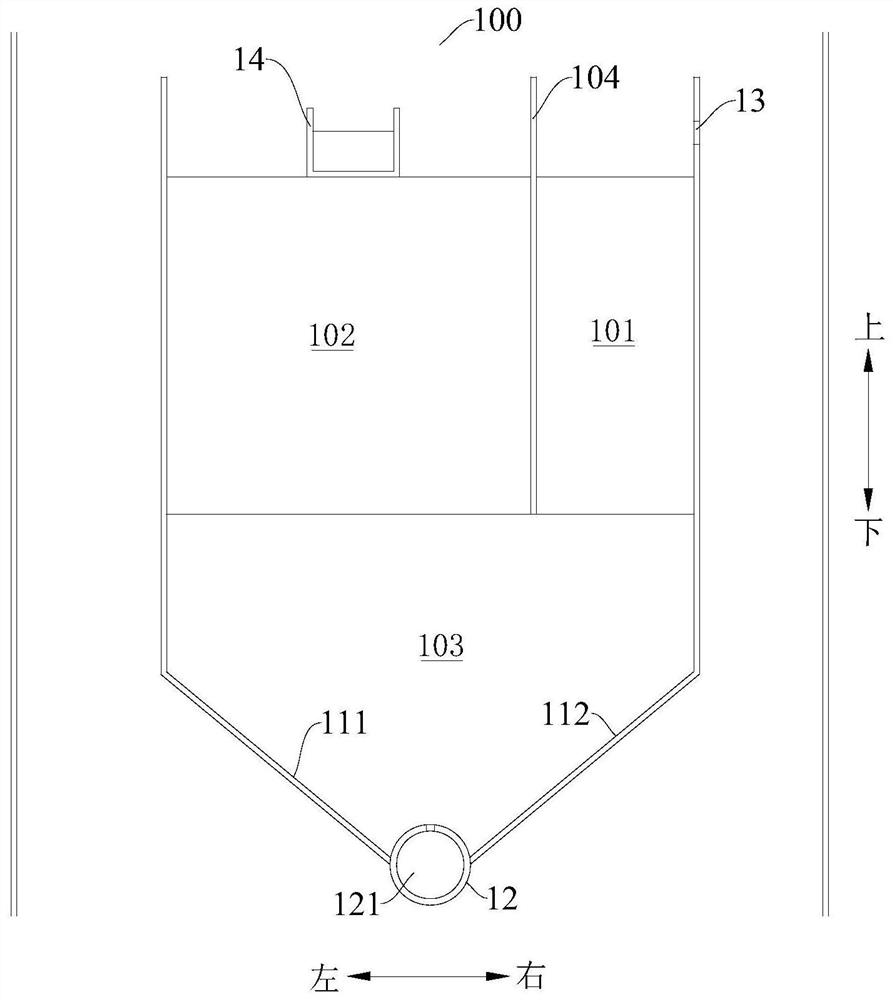

[0037]BelowFigure 1 - Figure 2A three-phase separator 100 in accordance with an embodiment of the present invention is described.

[0038]Such asfigure 1 withfigure 2 As shown, the three-phase separator 100 according to an embodiment of the present invention includes a main body 10, and the body 10 defines a degassing chamber 101, a precipitation chamber 102, and a storage chamber 103, and the storage chamber 103 is located below the degasser 101 and the precipitation chamber 102. The degasser 101, the sedimentation chamber 102 is arranged at the horizontal direction, and the storage chamber 103 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com