Method for evaluating macroscopic residual stress of steel wire

A technology of residual stress and steel wire, applied in force/torque/work measuring instruments, using stable tension/pressure to test material strength, measuring devices, etc., can solve problems such as complex measurement procedures, expensive equipment, and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、1860

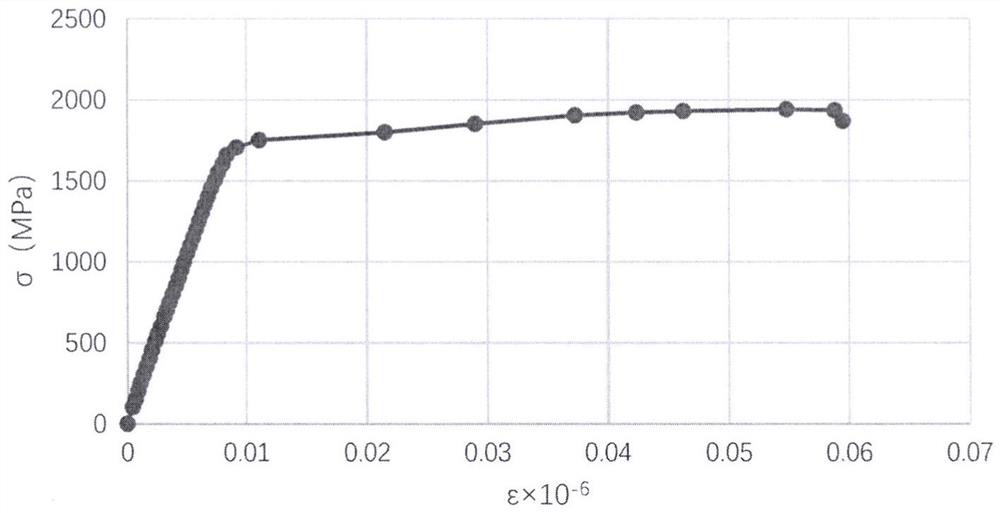

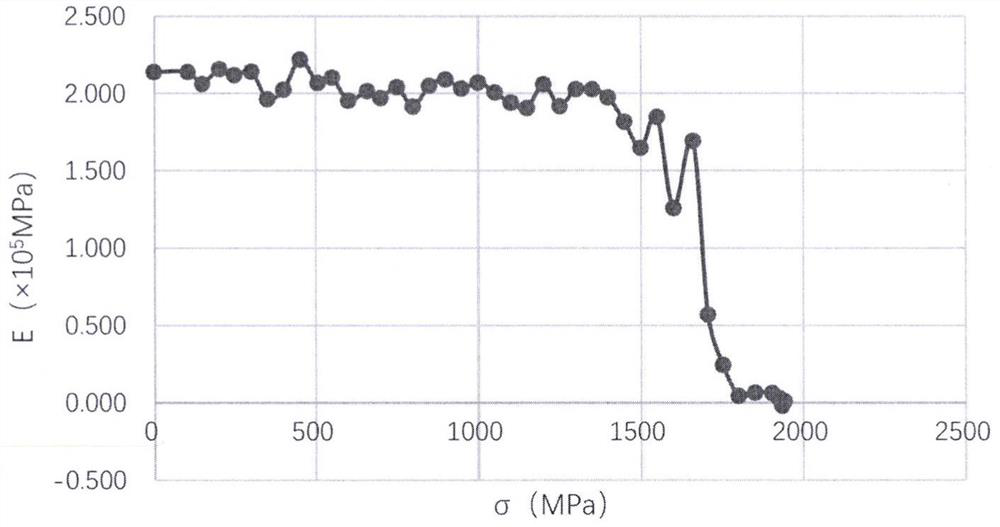

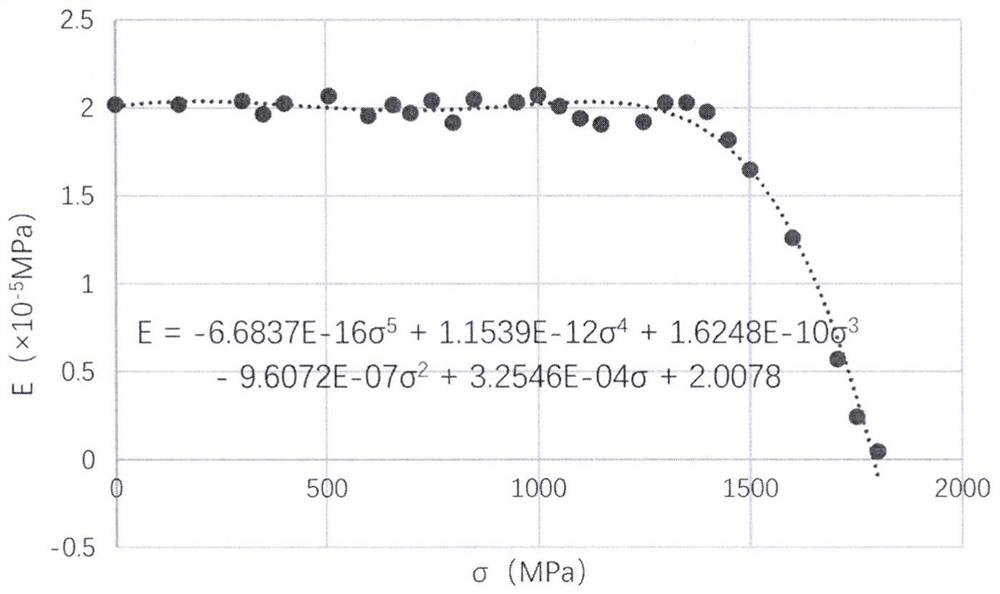

[0042] Embodiment 1, 1860 grade high-strength low-relaxation carbon steel wire

[0043] A high-strength low-relaxation carbon steel wire with a diameter of 5.2mm and a standard strength of 1860MPa is loaded in stages at 50MPa. Under the nominal stress of 1400MPa, use a 50mm gauge length extensometer to measure the strain under each load; after exceeding 1400MPa, use a universal testing machine The displacement of the moving beam is used to estimate the strain at each loading level. The measured stress-strain curve is attached figure 1 , the instantaneous elastic modulus of each level of loading point (approximately replaced by the secant elastic modulus of each level of loading) see the attached figure 2 . attached by figure 2 It can be seen that when the nominal tensile stress is not greater than 1000MPa, the instantaneous elastic modulus basically remains unchanged in a straight line, so the average value of the secant elastic modulus under loading at various levels below...

Embodiment 2、1250

[0045] Embodiment 2, 1250 grade high-strength stainless steel wire

[0046] A high-strength stainless steel wire with a diameter of 5.6mm and a standard strength of 1250Mpa is loaded in stages at 50MPa. Below 1000MPa, use a 500mm gauge extensometer to measure the strain under each load; after exceeding 1000MPa, use a universal testing machine to move the beam displacement to estimate each Strain under load. The measured stress-strain curve is attached Figure 5 , the instantaneous elastic modulus of each level of loading point (approximately replaced by the secant elastic modulus of each level of loading) see the attached Image 6 . attached by Image 6 It can be seen that when the nominal tensile stress is not greater than 500MPa, the instantaneous elastic modulus remains basically unchanged in a straight line, so the average value of the secant elastic modulus under loading at various levels below 500MPa or the secant elastic modulus of 0-500MPa can be used to approximate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com