Advanced plan scheduling system based on finished vehicle production

A technology of planning and scheduling and production planning, applied in manufacturing computing systems, calculations, instruments, etc., can solve the problem of long time-consuming manual production scheduling, and achieve the effect of improving market responsiveness and ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

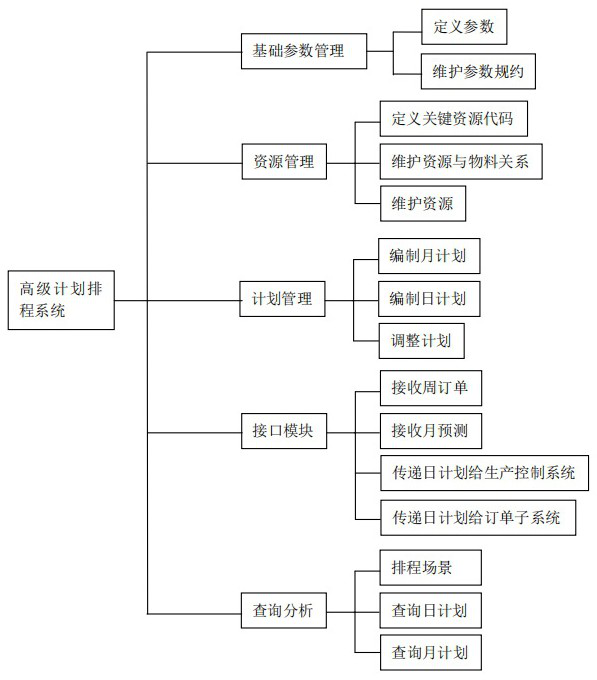

[0028] Such as figure 1 As shown, in this embodiment, an advanced planning and scheduling system based on vehicle production, the advanced planning and scheduling system based on vehicle production includes:

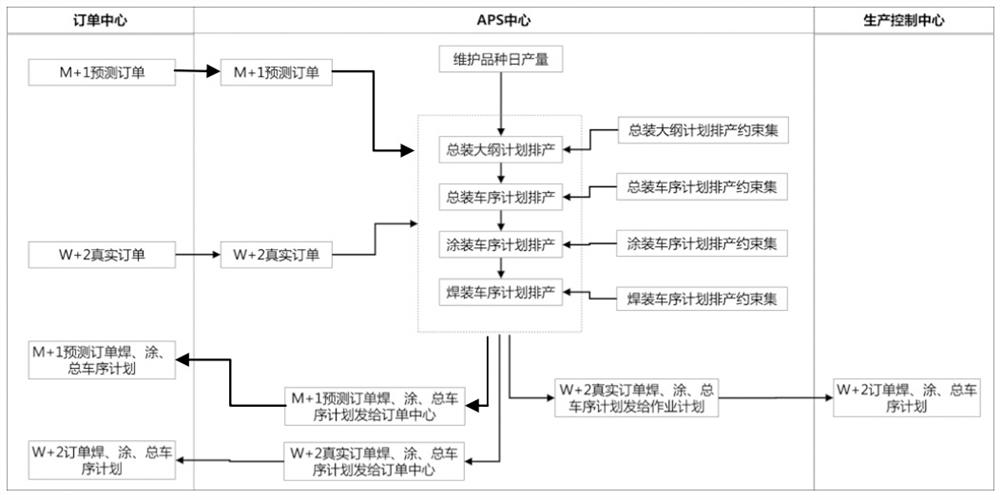

[0029] Order subsystem: used to receive externally input order information, generate forecast orders and real orders, and send the forecast orders and real orders to the APS subsystem, and at the same time receive the forecast order vehicle sequence planning schedule table and real orders returned by the APS subsystem Order vehicle sequence planning and production schedule table for users to view order information;

[0030] APS subsystem: used to receive the forecasted order and real order sent by the order subsystem, gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com