Wafer defect identification method and device

A recognition method and recognition device technology, applied in image data processing, instruments, calculations, etc., can solve problems such as complex manufacturing process and wafer defect loss, and achieve the effect of improving defect recognition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

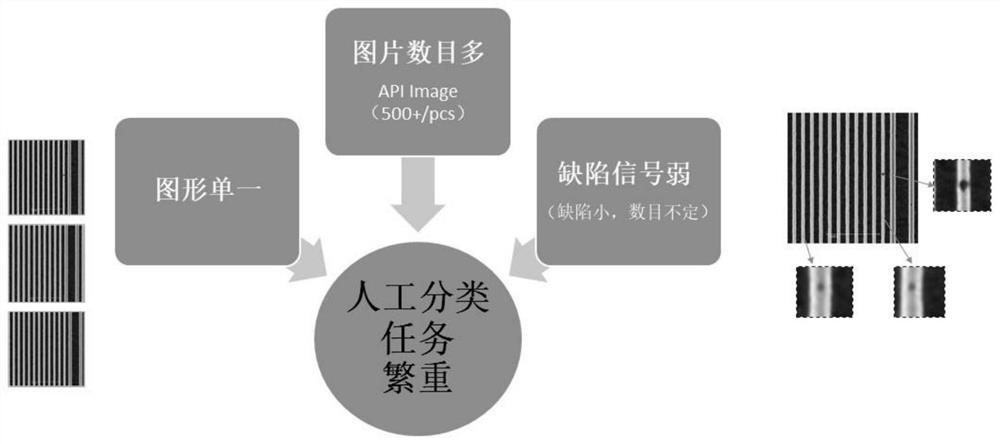

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

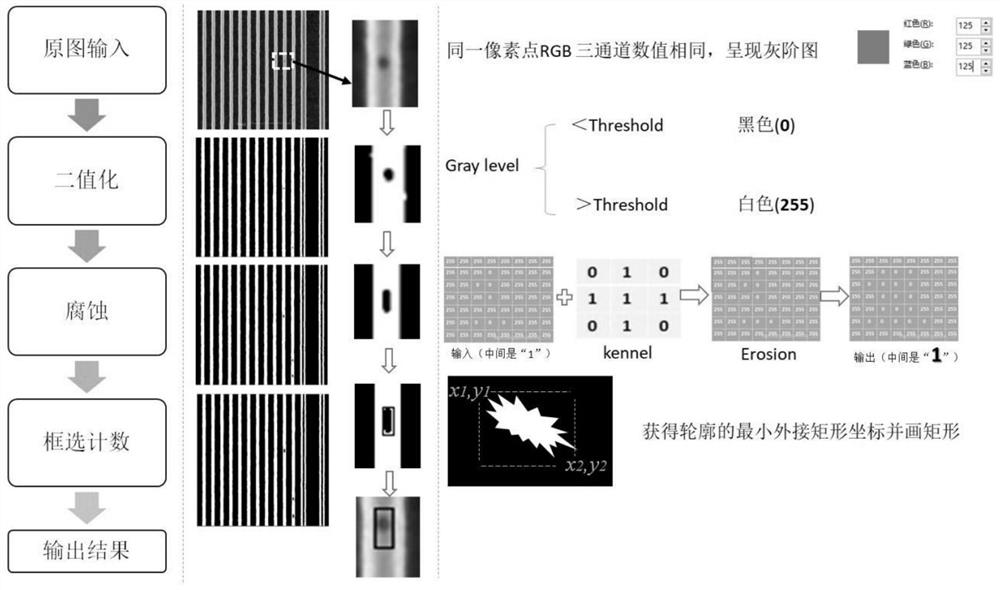

[0040] The identification method of wafer defect described in the present invention comprises:

[0041] A wafer defect image is acquired, and the wafer defect image includes a grayscale image.

[0042] performing weak signal discrimination processing on the wafer defect image to obtain a processed wafer defect image; the weak signal discrimination processing is used to distinguish the wafer defect in the wafer defect image from the background.

[0043] Perform positioning and frame selection on the wafer defects, count the wafer defects selected by the positioning and frame, and obtain the number of wafer defects in the wafer defect image.

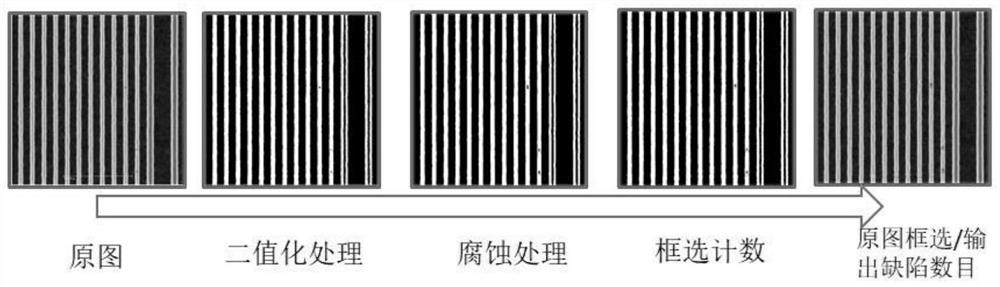

[0044] For specific times, refer to figure 2 and image 3 shown, including the following steps:

[0045] First obtain the original image of the wafer defect image, such as a grayscale image. The RGB three-channel values of the same pixel in the original image are the same, presenting a grayscale image. image 3 The value of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com